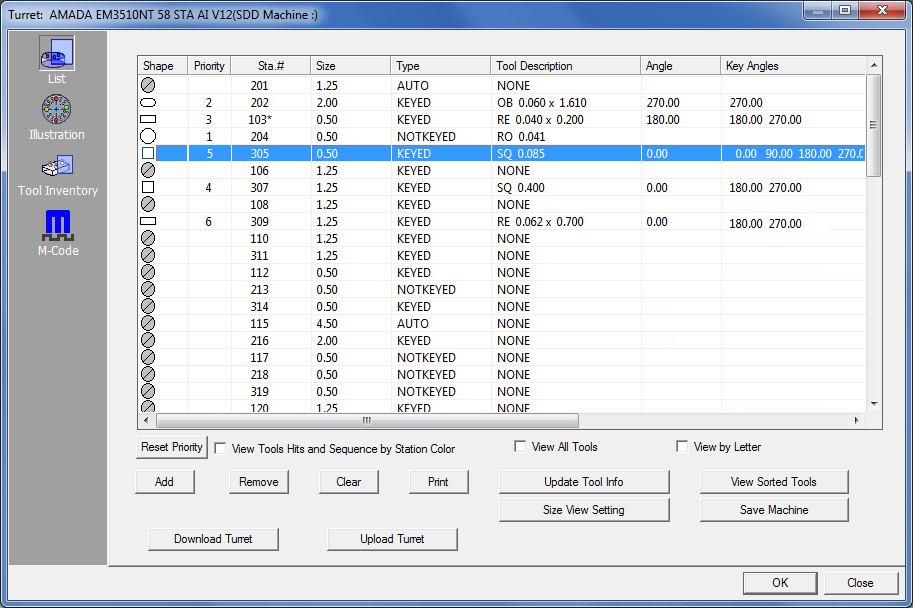

Turret Window

The

Turret window is a graphical representation of all the stations in your

machine. Scroll bars along the side and bottom allow you to navigate through

the window. A set of command buttons along the bottom also allows you

to manage your turret setup. The window is divided into these panels:

List View,

Illustration View,

Tool Inventory View

and M-Code View.

|

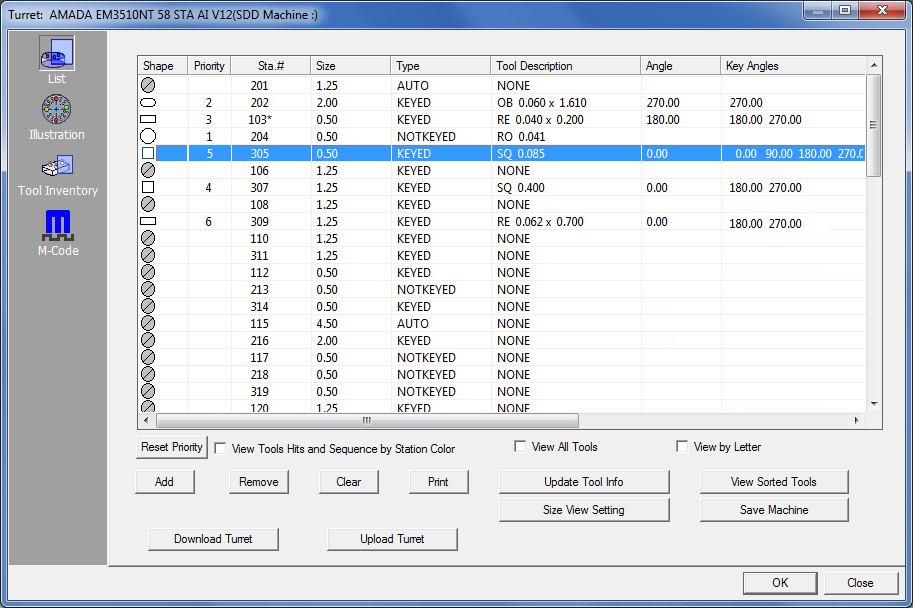

The

system will display the List view by default when you open

the Turret window. Columns are: Shape, Sta. # (Station Number),

Size, Type, Tool Description, Angle, Key Angles, Min Over Travel,

Max Over Travel, No Punch Zone and Tool Comment.

|

|

Column

Title |

Description |

Shape |

A

graphical icon that represents the tool shape appears in this

column. Double-click a station/row with a tool in it to open the

Station dialog to create and edit stations.. |

Priority

|

By

entering a value in the Priority option, the user can assign a

sequence priority to individual tools in the system in a standard

machine setup. (Compare this to the Sequence Priority feature

in Preferences>Tooling, which

can prioritize certain tool types

in a sequence, but not specific tools.) Double-click the tool/row

to open the Station window

and enter a value in the Priority field.

A

value of "1" assigned to a tool will cause that tool

to be sequenced first. The user may prioritize the tools as desired.

See Creating &

Editing Stations for more info on assigning priorities to

tools. Click the Reset Priority

button to return all priority values to the default setting, which

is pulled from the Sequence Priority feature in Preferences>Tooling.

When

the user hits the Save Machine

button in this window the tool sequence priorities are then saved

with the machine and become the default

for this machine. (This will NOT affect the original Sequence

Priorities in Preferences>Tooling.)

When

a sheet using this machine is sequenced, these priority values

will be passed on to the Tool

Sequence Priority Window in Sequence Features. Tool priorities

can then be adjusted in that window on a per-session basis. |

Sta.

# |

The

station or tool ID number.

A

letter displaying next to the Station number indicates that the

tool has been designate for special use. These letters include:

T (Trimming), R

(Remnant), L (Reliefs),

P (Pierce), S

(Scribing), M (Microjoints).

An

asterisk (*) indicates that the tool has already been assigned

and is in use.

(See

Station Tool Information Dialog.) |

Size |

The

size of the station. This column displays the actual size, in

inches, or the letter size equivalent. |

Type |

The

station type -

KEYED The station is keyed to

hold the tool in a given angle; NOTKEYED

The station has no key and is used with ROUND tools; MANUAL

Allows the user to override the original key position; AUTOINDEX Tool can freely rotate

to any angle as needed;

CLAMP Used for staging a clamp

with the tool holder (for Trumpf-style clamp holders). |

Tool

Description |

A

description of the tool currently installed in the station. If

a station is empty, then “NONE” appears in the field. |

Angle |

The

angle of the tool when it is assigned to a turret station. |

Key Angles |

Additional

angles that the turret station can allow if needed. |

Min.

Overtravel |

The

minimum amount of allowed overtravel. |

Max.

Overtravel |

The

maximum amount of allowed overtravel. |

No Punch

Zone |

The

area around the clamps that cannot be punched. |

Tool

Comment |

Enter

information about the tool, for example the location where the

tool itself is stored. When saved, this read-only information

is viewable in the Tool

Comment column in the Tool Inventory - List

View and Tool Inventory

panels.

Note: When

generating NC code, data from the Tool Comment column will be

added to the setup sheet and will be viewable in the NC Sequence

Viewer.

For

info on entering a comment see the Tool

Information Dialog. |

Option |

Description |

View

Tool Hits and Sequence by Station Color |

This is a toggle switch. If you activate the option, the tool hits

appear on the part or sheet in the colors you assigned using the

Station Color List or Station Color Button in the Station window.

|

View

All Tools |

This

is a toggle. If you activate the option, the system only lists

those tools in the Tool List that are available when the selected

turret station is of the same size and type. |

View

by Letter |

This

is a toggle. If you place a check mark in the check box, the system

will display the station sizes as letters in the Turret and Station

windows. If you remove the check mark, then the actual stations

sizes display. |

Command Buttons |

Reset

Priority |

Click

to return the Priority values in each cell to the default setting.

See Priority above for full info. |

Add |

To place

tools in the turret click the Add button and the Turret

window displays the Tool List on the right side. Tool List will

display the tools in the currently loaded Tool Inventory. The

tools are grouped by type, i.e., Round, Double D, Single D, Obrounds,

Squares, etc.

You

can save tools with the machine setup to create a standard turret

load.

Notes:

1) When you use the Auto Sheet, Auto Part or Assign options for

tool assignments, the system automatically adds the tools to the

turret.

2) You can only place tools in empty turret stations, i.e. stations

having the Tool Description of “None”.

3) When you select a tool in the Tool List that matches a station

size in the turret, the system will highlight the corresponding

station(s) in List View to indicate those stations that will accept

the selected tool.

4) The system remains in Add Tool mode until you select another

option.

5) The special tools appear at the very end of the Tool List. Note:

Changes made to a Special Tool in the Special

Tool Designer module will automatically be passed to the Tool

Inventory. |

Remove |

To

remove a tool from a station, select the station containing the

tool and then click the Remove button in the turret window. |

Clear |

Click

the Clear button if you want to completely change your turret

setup, or remove all of the unused tools from the turret. A message

window appears asking if you want to clear All Tools, or

just the Unused Tools from the turret. Select the appropriate

option and click OK. Click Cancel to exit without clearing any

tools from the turret. Remember that Clear Tools will not remove

tools from Fixed Stations.

|

Print

Turret |

Click

the Print button if you want to print your turret setup. When

the system prompts you for confirmation, press <Y> for Yes

or <N> for No. The report lists the station number, size,

type, tool, angle, over travels, key angles and no punch zones.

The report may be split over several pages, but the station numbers

appear on all the pages. |

Update

Tool Info |

If

you have loaded a machine or sheet that does not include tool

information and the Tool Inventory does include tool information,

use the Update Tool Information button to update every tool in

the turret. (See also Update Button under Station

Tool Information Window.) |

View

Sorted Tools |

The

View Sorted Tools button is a toggle. You can use this button

to display only those tools, sorted by shape and size, which are

actually used to process the part or sheet. The remaining stations

without tools are hidden from view. Click the button again to

view all the turret stations and installed tools. |

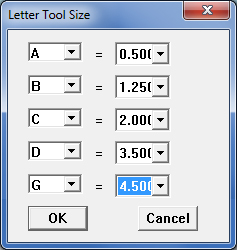

Size

View Setting |

Some

machines use a letter designation, such as A, B C, etc., to indicate

the station size and type, while other machines use the actual

tool size to define the turret station size. The Size View button

allows you to define the station size and use either a letter

designation for the station or the actual size.

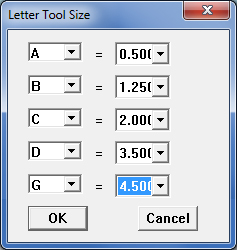

Click

on the Size View Setting button and the Letter Tool

Size dialog appears.

Clicking

on any drop-down list on the left displays the letter designation

for a particular station size in the turret. Clicking on any drop-down

list on the right displays the actual station sizes.

If

necessary, you can correct the letter designation and size for

each station type. Select a letter designation from one of the

lists on the left and then select the appropriate size from one

of the lists on the right. Click OK to save the changes

or click Cancel to exit without saving. |

Save

Machine |

Click

the Save Machine button to save any changes. If the system prompts

you to overwrite the existing machine, click OK.

Saving Changes to the Turret

The changes you make in the

turret are saved when you save the sheet. However, if you also

want to save this as a new machine file, use the Save As… option

under the File menu to assign a new name. (See Machine

File.)

Note: Changes made to a Special Tool

in the Special Tool Designer

module will automatically be passed to the Tool Inventory. |

Download

/ Upload Turret |

Download

an SDDJ Turret Layout to the AP100US Turret File and tool inventory.

(Available only if connected to an SDDJ Server.)

Upload

an AP100US Turret file to the SDDJ database.

Note:

These options are available only for AP100US users, who are connected

to an SDDJ Server. |

OK /

Close |

Click

OK to save any changes

and exit The Tool Inventory window.

Click

the Close button to exit the Tool Inventory window without

saving any changes. |

Notes: |

|

1. You

can toggle between the List, Illustration and Tool Inventory views

by clicking their respective icon buttons along the left-hand

side of the Turret window. |

2. If

your turret does not display any stations or just one station,

select the Turret Info option from the Machine menu and

define the station information before attempting to add tools

to the turret. |

3. If

you are using an existing machine, make sure the information for

each station is correct. If you are creating a new turret, you

will need to enter the information for each line. (See Creating

and Editing Stations .) |

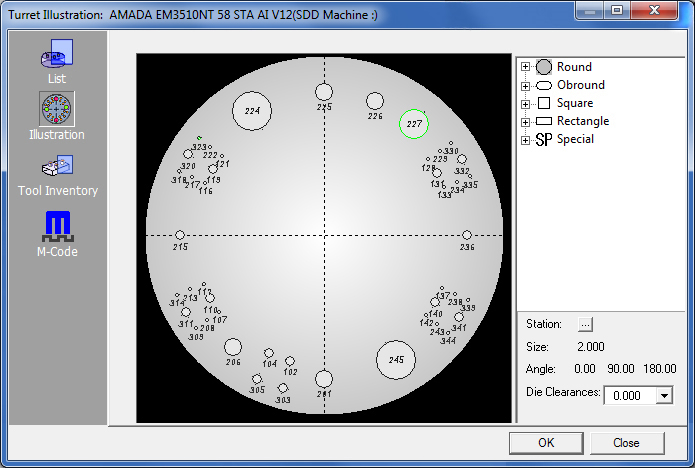

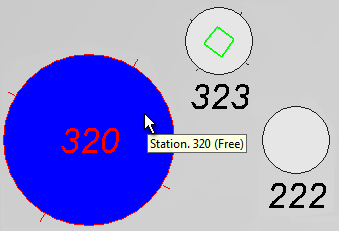

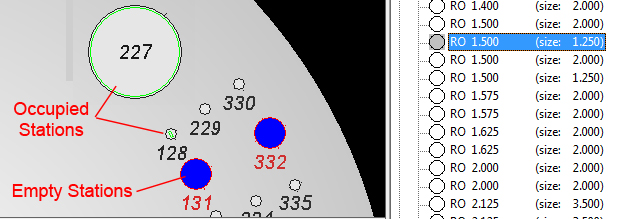

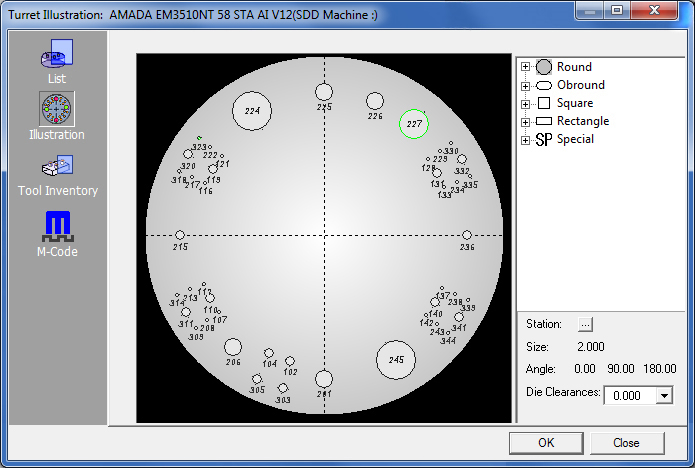

Clicking the

Illustration button will display a graphical layout of the currently

loaded turret within the Turret Illustration window. The station number

for all stations displays by default.

While

the cursor is over the display, depress and hold the center mouse wheel

and drag the entire display so that a particular station is at the center.

Roll the mouse wheel button to zoom in and zoom out.

(See

Turret

Illustration and Design and Turret

Types for more information.)

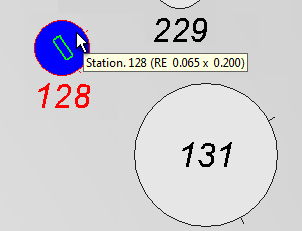

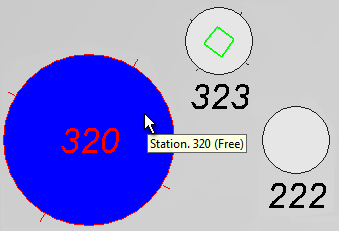

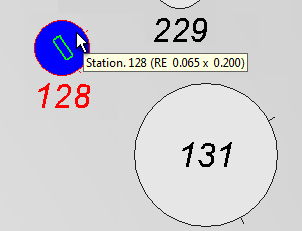

Passing

the cursor over a turret station will highlight the station in blue and

its number in red. The system will also display information for that station

in a tag. If a station has a tool assigned, the tool will be highlighted

in green, and tool information will display in the tag. See the illustrations

below.

If there is no tool currently installed in the

station the word “Free” will appear

in the tag after the station number.

When

a tool is installed the tag indicates the tool type and tool size (RE

- rectangle

-, size = 0.035 x 0.400). The tool installed in Station 128 is outlined in green.

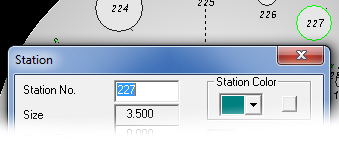

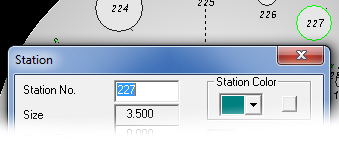

Double left-click

on any station to open the Station dialog.

From here edit station characteristics. (See

Creating and Editing Stations for more info.)

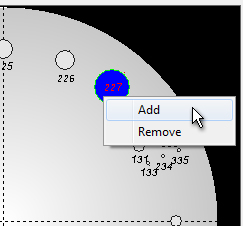

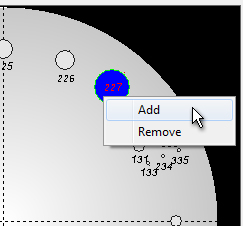

Loading tools

into the turret is permitted in this window. Right-click on a station

in the turret illustration and click on Add to open the Add panel.

From the panel drag and drop tools from the Tool Inventory into the stations

in the Illustration view. To

remove a tool from a station, right-click on the station and click Remove.

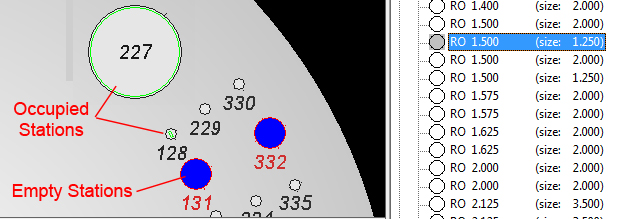

When a tool

is selected (as in the diagram above) all empty stations suitable for

the tool (according to size) will be highlighted in blue. Occupied stations

display in green. Drag and drop a tool from the Tool Inventory on the

right over to a BLUE station

in the turret illustration on the left.

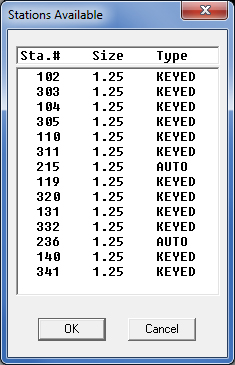

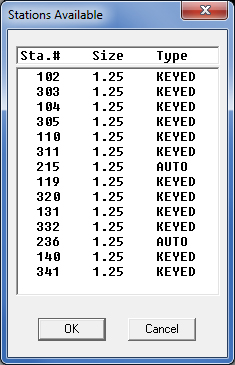

Click on

the Station

button to open the Stations Available dialog box shown on

the left. After a tool is selected in the Tool Inventory panel the button

becomes available. Select an available

station and click OK to place the tool that is already selected into the

station.

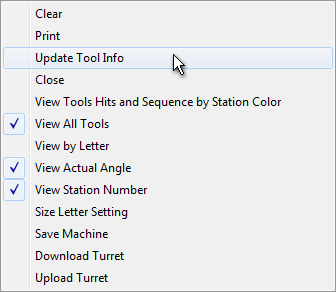

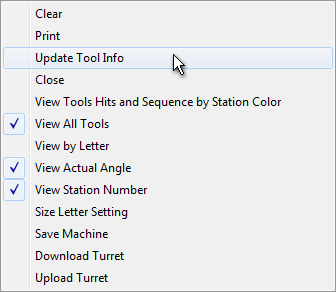

Right-click

a blank area of the turret illustration to display the flyout menu with

turret setup options as discussed above in Turret Window – List View .

|

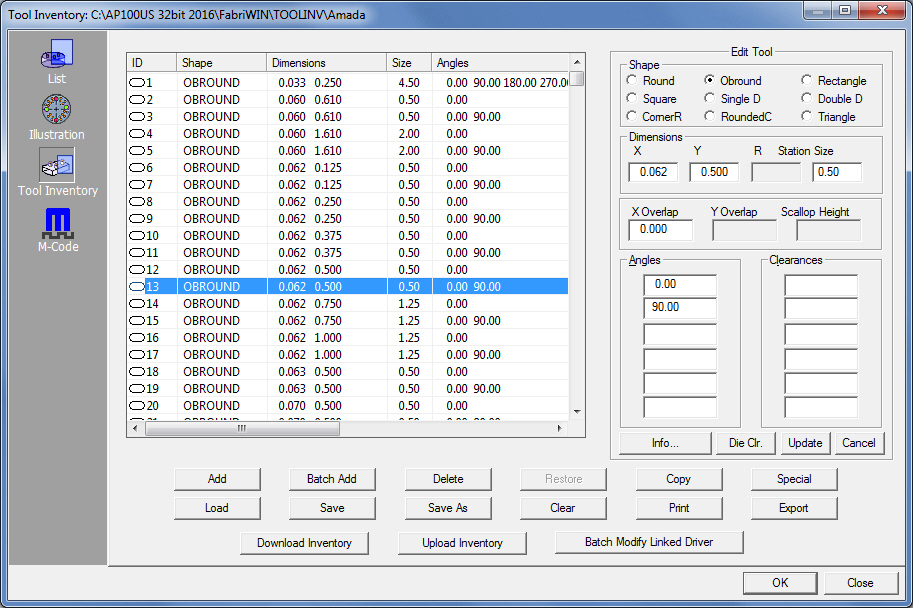

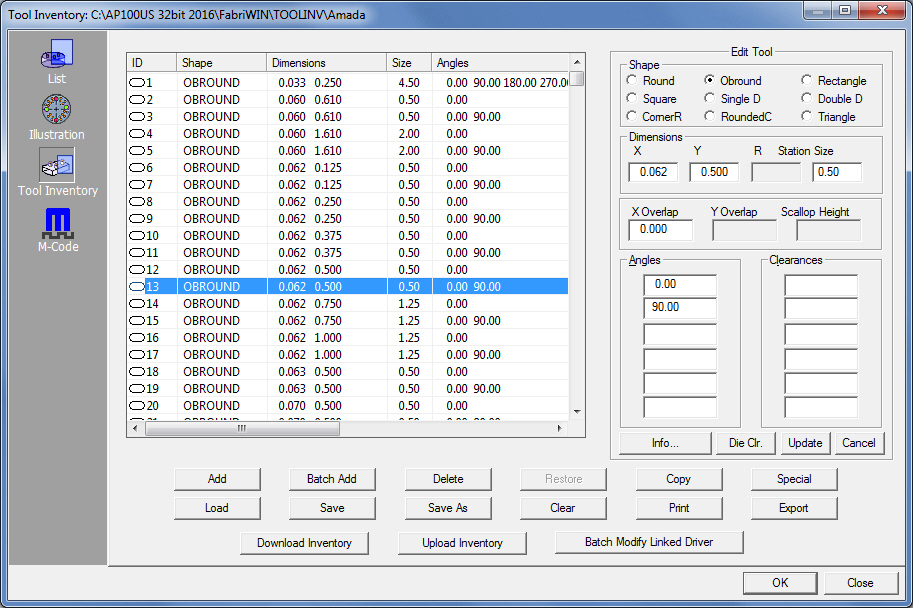

If

you click the Tool Inventory tab, the system will switch

to Tool Inventory mode and list all the tools in the currently

loaded Tool Inventory.

To

edit an existing tool, double-click any Tool/Row to open the Edit

Tool panel shown here. The panel will be populated with values

for the current tool that may be edited. |

|

Column

Title |

Description |

ID |

Displays the Tool ID. |

Shape |

The

shape of the tool (such as “Round” or “Rectangle”) is given here. |

Dimensions |

The

Dimensions of the tool is shown here. |

Size |

The

Size of the tool is shown here. |

Angles |

Displays

the angle value that was entered in the Add New Tool dialog. |

Clearances |

Displays

the Die Clearance value(s) that have been entered for the Tool.

|

Tool

Comment |

Enter any necessary information about the

tool, such as where the tool itself is stored.

Tool Comments must be added through the Tool

Information Dialog.

Note:

When generating NC code, data from the Tool Comment column will

be added to the setup sheet and will be viewable in the NC Sequence

Viewer. |

Option |

Description |

Add |

The

Add option allows the user to add a tool to a new or existing

inventory. Click the Add button and the Add New Tool

dialog displays on the right side of this window. For info on

adding new tools, see Creating and Editing

Tools.

To

display the Edit Tool dialog in this place, double-click

any existing tool in the inventory. |

Batch

Add |

Batch

Add can add multiple tools to the inventory at one time, instead

of adding individual tools one by one.

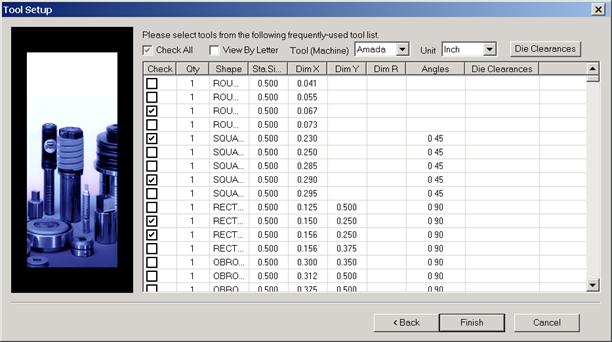

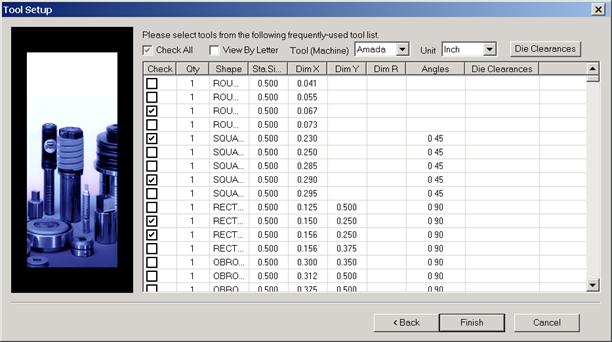

Click

the Batch Add button and the Tool Setup windows displays. Begin

by picking a tool inventory from a listed company, and then simply

check the tools you want to add and click Finish button. The tools

you selected are now added.

Tool

Setup Window

Refer

to these instructions for Batch Adding.

In

the first dialog box, select a tool inventory from a specific

manufacturer.

Click Next

to go to the main Tool Setup dialog. |

|

In

the next Tool Setup dialog, check the tools that are to

be Batch Added and click Finish to load those tools.

Click Back to return to the dialog above if necessary. |

|

|

Delete |

The

Delete option removes the currently selected tool from

the Tool Inventory. Click the line belonging to the tool you want

to delete, and then click the Delete button. The tool is

removed from the list. If you accidentally delete the wrong tool,

click the Restore button to restore

it. |

Restore |

The Restore

option reverses the Delete command and

restores a tool. Click the Restore button and the last

tool you deleted reappears in the Tool Inventory.

Note:

You must use Restore before exiting the Tool Inventory window.

Once you save your changes and exit, you cannot restore any deleted

items. |

Copy |

To add

a tool that is similar or identical to an existing tool in your

inventory, click the Copy button. Click the line belonging

to the tool you want to copy and then click the Copy button.

The

Copy Tool panel (which functions in the same way as the Add New Tool

and Edit

Tool dialogs) will appear and display information

for the original tool. Modify the information as needed. When

the information is correct, click OK and a copy of the

tool appears in the list. |

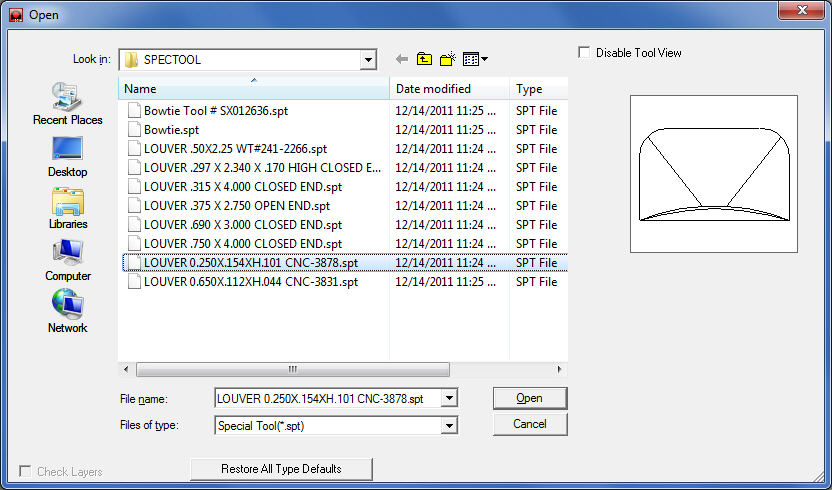

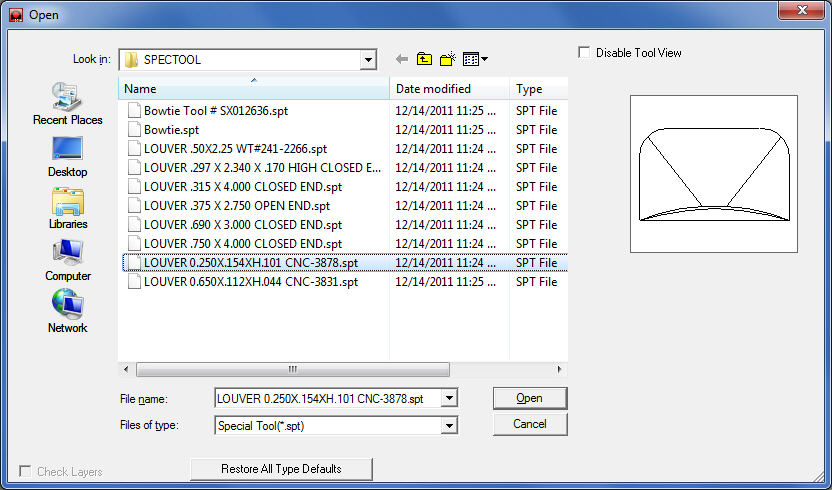

Special |

Special

tools are tools having custom shapes, rather than standard shapes.

You must draw and record the station information for your special

tools before you can add them to your Tool Inventory. (See Designing Special Tools.)

To

add an existing special tool to the inventory, click the Special

button. When the Open dialog box appears, navigate to the desired

drive and folder, and then select the file name of the special

tool. Click Open to load the special tool into the current

inventory. You can load as many special tools as needed. Click

Close to exit the Open dialog box.

|

Notes:

Special tools cannot be edited in the Tool Inventory module. To

edit a special tool, select the Design Special Tool…

option from the Tool menu to open the Special Tool window.

When a Special Tool is edited in the Special Tools Designer, changes

made will automatically be updated to the Tool Inventory.

See

Designing Special Tools.

|

Load |

The

Load button displays the Open dialog box. If you want to

change an existing tool inventory, use Open to load that tool

inventory so you can make corrections.

In

addition to standard inv files, the user may choose to load from

Tool Inventory files in .XLS or .CSV formats. From here it is

also possible to create and edit .xls and .csv files. See Export below for more info on

this. |

Save |

You

must save the Tool Inventory after modifying it. If you have created

a new tool inventory, click the Save As button.

Navigate to the desired drive and folder, and then type a name

in the File name: text box. Click Save and then Close

after the system saves your tool inventory.

For

an existing tool inventory that you want to save under the same

name, click the Save button.

Note:

The system prompts you save the changes before you exit. Press

<Y> for Yes, <N> for No, or <Escape> to cancel.

If you press <N>, any changes you made are permanently lost.

If you want to save the inventory under a different name, press

<Escape>, and then use Save As. |

Save

As |

You

must save the Tool Inventory after modifying it. If you have created

a new tool inventory, click the Save As button. |

Clear |

The

Clear button allows you to clear the current inventory

and start a new inventory. You may want to do this if you are

creating several tool inventories. However, if you use Clear,

make sure to save the tool inventory under a different name before

you exit the Tool Inventory. Otherwise, you will overwrite the

contents of the original tool inventory. |

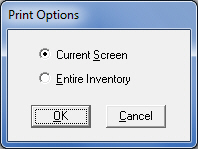

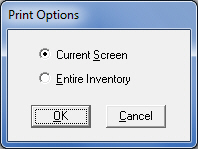

Print |

If you

want to print a list of the Tool Inventory, click the Print

button. The Print Options window appears. Select either Current

Screen or Entire Inventory, and then click

OK.

Select

Current Option if you

only want to print those tools that are currently visible within

the Tool Inventory window.

Select

Entire Inventory if you

want to print every record in the Tool Inventory. |

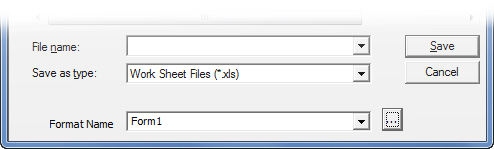

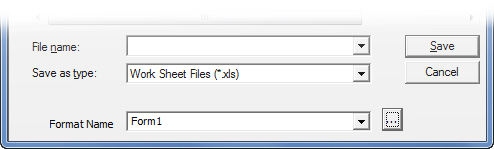

Export |

To

export Tool Inventory files in .XLS or .CSV formats, click Export. The Save As dialog will

open allowing the user to save directly to the TOOLINV folder

in the AP100US installed folder in either .xls or .csv format.

The

Save As folder contains a Format

Name and button. The user may select from existing formats,

or click the button to open the Format Options window to create

or edit formats.

See

Exporting Files in XLS or CSV formats

in the Material Files folder for more info on creating and editing

.xls and .csv files. |

Download

/ Upload Inventory |

Download

an SDDJ Tool Inventory to the AP100US Tool Inventory File. Upload

a Tool Inventory to update the SDD Tool Inventory. (Available

only if connected to an SDDJ Server.) |

Batch

Modify Linked Driver |

If a user

needs to map a Standard Item to an item that needs a value input,

this button may be selected to open the Punch

Condition Mapping window. Here the

user will see current M-Codes and make changes to the M-Codes

mapping as needed. |

OK /

Close |

Click

the OK button when you have recorded all the additional tool information.

Click Cancel to exit the Tool Information window without saving

any changes. |

Turret Window - M-Code View

AP100US

supports MCA files that contain conditions for Special Tools. Used with

Combo and Punch machines, this read-only MCA info can help the user to

maximize special tool actions, which will speed up special tool processing

and result in an improved Run Time. See View

Run Time for more info.

AP100US

supports MCA files that contain conditions for Special Tools. Used with

Combo and Punch machines, this read-only MCA info can help the user to

maximize special tool actions, which will speed up special tool processing

and result in an improved Run Time. See View

Run Time for more info.

When a newer

model Amada punch or combo machine is loaded, along with an MCA file (see

Machine>Description window for

more info) the MCode icon displays. Click the button to display the M-Code

panel.

.

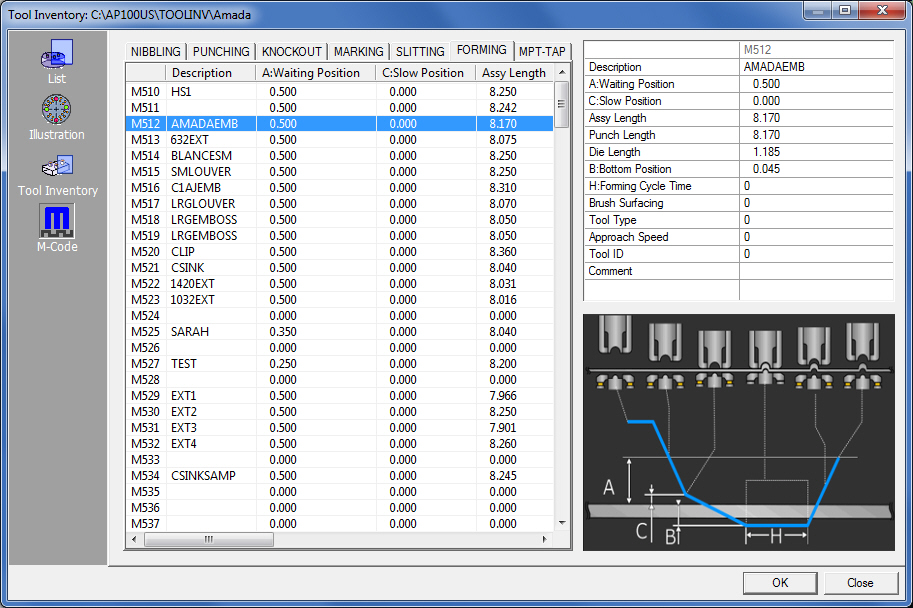

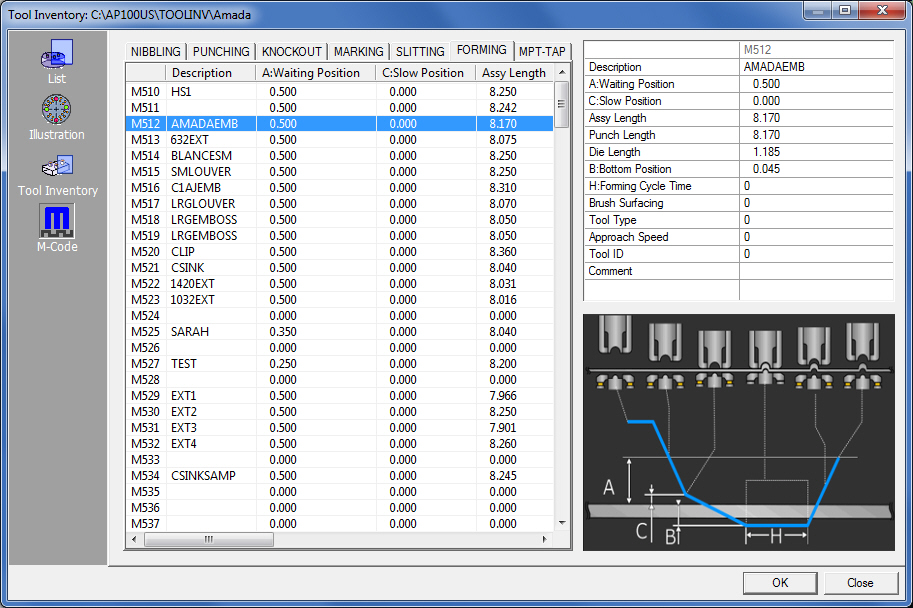

When a tab is selected (such as Forming shown

here) the image

at lower right shows an explanation of columns in that tab

Importing MCA Files

MCA files that are created by an operator on the machine controller can

be imported into AP100US. Using a portable memory device attached to the

machine controller, export a copy of the MCA file and then place that

copy in the C:\AP100US\ConditionFile folder. The imported MCA file can

then be opened in AP100US by clicking the Add

button next to the Machine Settings>MCA File field. When the Open dialog appears, double-click

a .mca file to add it to the field. See the Machine>Description window for

more info.

Tabs and Column Headers

NIBBLING

(Punching out a part or slug using many tool hits in rapid succession.)

Description: The description or

name assigned to the tool by the operator/user when the tool was first

added to the inventory.

A: Waiting Position: Position of

a tool above the sheet when the sheet is in motion.

B: Bottom Position: Maximum depth

of the tool after the hit when it has passed through the sheet towards

the die.

Comment: Comment added to the tool

by the operator/user.

PUNCHING

(Use of punching tools to process a sheet as opposed to laser cutting.)

Description: The description or

name assigned to the tool by the operator/user when the tool was first

added to the inventory.

A: Waiting Position: Position of

a tool above the sheet when the sheet is in motion.

C: Slow Position: Position of the

tool when it slows down just prior to the actual hit.

B: Bottom Position: Maximum depth

of the tool after the hit when it has passed through the sheet towards

the die.

Comment: Comment added to the tool

by the operator/user.

KNOCKOUT

(Removing a slug with a single hit from a tool.)

Description: The description or

name assigned to the tool by the operator/user when the tool was first

added to the inventory.

A: Waiting Position: Position of

a tool above the sheet when the sheet is in motion.

C: Slow Position: Position of the

tool when it slows down just prior to the actual hit.

Assembly Length: Overall length

of actual tool.

Punch Length: Length of the actual

punch that is inside the tool.

Die Length: Length or overall thickness

of the die itself.

B: Bottom Position: Maximum depth

of the tool after the hit when it has passed through the sheet towards

the die.

High Speed Knockout: Actual speed

of the tool when making the hit. The user may choose Normal or High.

Tool ID: The ID number assigned

to the tool.

Comment: Comment added to the tool

by the operator/user.

MARKING

(Use of a special tool to stamp a name or logo on a part.)

Description: The description or

name assigned to the tool by the operator/user when the tool was first

added to the inventory.

A: Waiting Position: Position of

a tool above the sheet when the sheet is in motion.

C: Slow Position: Position of the

tool when it slows down just prior to the actual hit.

Assembly Length: Overall length

of actual tool.

Punch Length: Length of the actual

punch that is inside the tool.

Die Length: Length or overall thickness

of the die itself.

B: Bottom Position: Maximum depth

of the tool after the hit when it has passed through the sheet towards

the die.

High Speed Marking: Select Normal

or High to control the speed of a marking hit.

Tool ID: The ID number assigned

to the tool.

Comment: Comment added to the tool

by the operator/user.

SLITTING

(Similar to shearing, a tool and die work together to create a

"scissor" effect to make a slit in the material.)

Description: The description or

name assigned to the tool by the operator/user when the tool was first

added to the inventory.

A: Waiting Position: Position of

a tool above the sheet when the sheet is in motion.

Assembly Length: Overall length

of actual tool.

Punch Length: Length of the actual

punch that is inside the tool.

Die Length: Length or overall thickness

of the die itself.

B: Bottom Position: Maximum depth

of the tool after the hit when it has passed through the sheet towards

the die.

Bottom Position End: The final

position of a tool when the hit is completed.

Tool ID: The ID number assigned

to the tool.

Comment: Comment added to the tool

by the operator/user.

FORMING (The use of a tool to

modify the geometry of a part rather than removing a portion of the material.)

Description: The description or

name assigned to the tool by the operator/user when the tool was first

added to the inventory.

A: Waiting Position: Position of

a tool above the sheet when the sheet is in motion.

C: Slow Position: Position of the

tool when it slows down just prior to the actual hit.

Assembly Length: Overall length

of actual tool.

Punch Length: Length of the actual

punch that is inside the tool.

Die Length: Length or overall thickness

of the die itself.

B: Bottom Position: Maximum depth

of the tool after the hit when it has passed through the sheet towards

the die.

Forming Cycle Time: The time required

to complete one complete forming hit.

Brush Surfacing: This switch (1=on,

0=off) enables the Floating Brush Table, which raises or lowers a brush

table under or near the turret. The machine in use must be equipped with

an FBT.

Tool Type: Select from Normal,

Ram Hold Down (With the tool at the final bottom position it will briefly

hold in place to complete the deformation of the material.) or High-Speed

forming.

Approach Speed: Speed of the tool

as it nears the material to execute a hit.

Tool ID: The ID number assigned

to the tool.

Comment: Comment added to the tool

by the operator/user.

MPT-TAP (Multi-Purpose Tool for

Tapping or drilling out a threaded hole.)

Description: The description or

name assigned to the tool by the operator/user when the tool was first

added to the inventory.

A: Waiting Position: Position of

a tool above the sheet when the sheet is in motion.

B: Bottom Position: Maximum depth

of the tool after the hit when it has passed through the sheet towards

the die.

Comment: Comment added to the tool

by the operator/user.