(Specifying

Tool Shapes and Parameters)

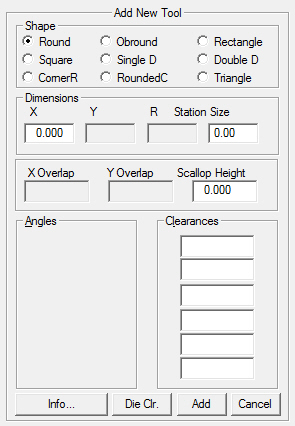

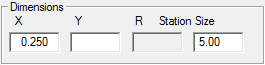

Specify the actual shape

or name of the new tool. Select one of the following names in

the Shape section of the Add New Tool window and then type

the values in the appropriate Dimension and Station Size text

boxes. The following table outlines the required parameters for

each tool shape.

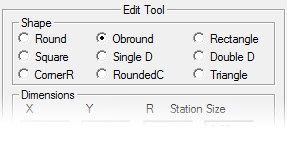

Note: When the Edit Tool dialog is

open, it is not possible to choose a new shape for an existing

tool. However, any other values may be configured for an existing

tool. If the Edit Tool dialog is open, begin Editing at Dimensions and Station

Size. |

Shape |

Parameters |

Round

(RO) |

A

round punch. You must specify an X dimension and Station

Size. |

Square

(SQ) |

A

square punch. You must specify an X dimension, Station

Size, and any angles allowed for the tool. |

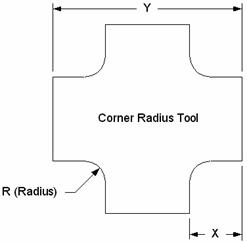

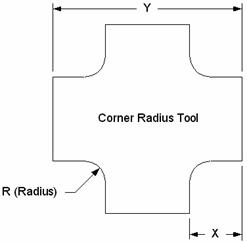

CornerR

(CR) |

A

four-way corner radius. The Y dimension is the overall

width of the tool, while the X dimension is the radius

and the extension of the web beyond the radius. The radius refers

to the actual radius of the four radii. See the Corner Radius

Tool diagram below. |

|

|

Obround

(OB) |

An

Obround punch. Specify an X dimension, a Y dimension,

and any angles allowed for the tool. |

Single

D (SD) |

A

Single D punch. Specify an X dimension, a Y dimension,

and any angles allowed for the tool. |

RoundedC

(RC) |

A

rounded-corner rectangle. This describes a rectangle punch that

consists of radius corners. Specify an X, Y, and

R dimension (the radius of each corner), and any keyed

angles. |

Rectangle

(RE) |

A

rectangular-shaped punch. Specify an X dimension, Y

dimension, Station Size and any angles allowed for the

tool. |

Double

D (DD) |

A

Double D punch. Specify an X dimension, a Y dimension,

and any angles allowed for the tool. |

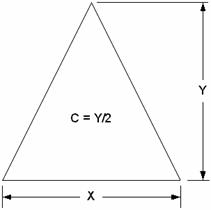

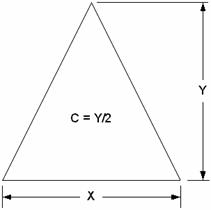

Triangle

(TR) |

A

triangle-shaped punching tool. The X dimension is the overall

width, the Y dimension the overall height, and the C

value is the distance from the base of the triangle to the center

point of the tool. The C value replaces the R when

Triangle is selected as the shape. The system automatically divides

Y by one-half to calculate C. For example, if you

specify Y = 1.5, the system returns the value of 0.750

for C by default. If necessary, you can overwrite this

value. |

|

|

|

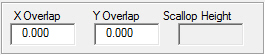

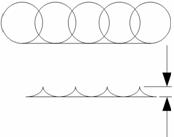

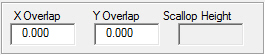

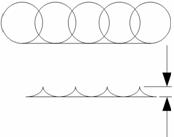

Overlap

describes the amount the tool hits should overlap in the horizontal

and vertical directions when punching patterns. Scallop height

is the amount of scallop created when the system nibbles patterns

with round tools. |

|

|

|

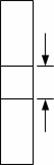

Tool

Overlap X |

Tool

Overlap Y |

Scallop

Height |

|

Option |

Description |

X Overlap |

For

non-round tools, the X Overlap value allows you to specify the

distance the tool should overlap in the X or horizontal direction. |

Y Overlap |

For

non-round tools, the Y Overlap value allows you to specify the

distance the tool should overlap in the Y or vertical direction. |

Scallop

Height |

For

round tools, Scallop Height allows you to define the height of

the scallop formed during a nibble process. The smaller the value,

the less the scallop. |

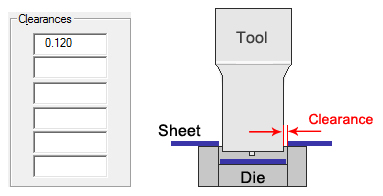

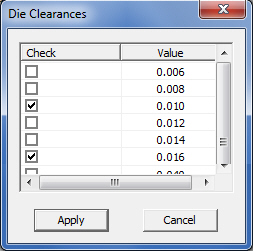

Die

Clearance is the space between the cutting edge of the punch and the cutting

edge of the die. The size of this space is defined by the thickness and

type of material being punched. For example, a 16-gauge blank may require

a value of 0.011.

Die

Clearance must be optimized for best performance. A clearance that is

too wide or too tight may spoil edge quality and even ruin the tool.

|

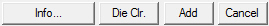

Info… |

The

Info… button displays the The Tool Information dialog.

Record supplementary preferences for the selected tool (such as

Travel Direction and Tool Comments) by enabling the Add

Additional Information to the Tool

option in the Tool Information window.

|

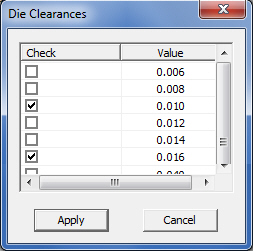

Die Clearances |

Click

to open the Die Clearances dialog. |

|

|

If

clearances are not manually entered, click Die

Clr. to open a dialog with common die clearance values.

Check one or more values to assign them to the tool.

Click

Apply to load these values into the Clearances fields

shown above. |

Add

Update |

After

a completely new tool has been created, click the Add

button to add it to the inventory. If you are editing an existing

tool, that same button will read "Update."

Click it to update the tool.

Note:

When exiting the main Tool Inventory window, it's still necessary

to hit Save. |

Cancel |

Click

Cancel to close the Add New Tool or Edit Tool dialog,

without saving any changes. |