Note:

The Cutting panel itself is only available if a cutting or combo machine

is currently loaded.

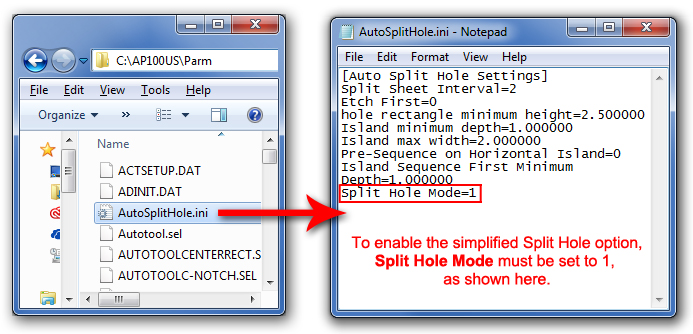

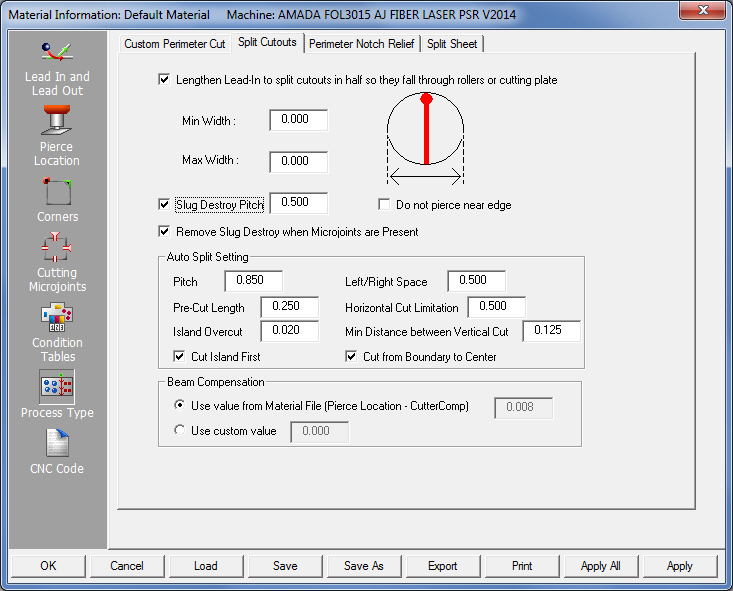

The Split Cutouts

submenu is switched OFF by default and does not display. To switch it

ON, go to the C:\AP100US\Parm folder and double-click the AutoSplitHole.ini

file to open it. The Split Hole Mode is set to 0 by default. Enter <1>

to switch it ON and then save the file. Restart the program and then check

ON the Enable Auto Split Menu

switch in Preferences>Cutting. The

Split Cutouts (Hole) submenu will then appear in the Cut Sequence tab.

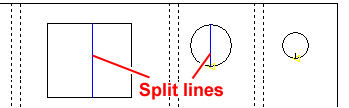

Similar

to the Split Sheet function, the Split Cutout option allows the user to

cut internal slugs into smaller sections in the X/Y directions to allow

them to fall through the slats of the shuttle table. There's no need to

reset the cutting sequence, because when the user places a split hole

cut, the system will automatically include this in the existing sequence.

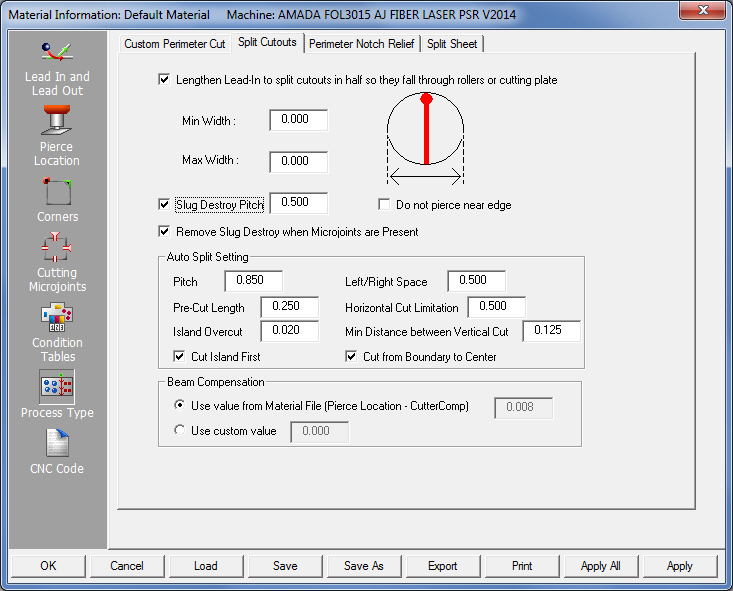

In

the Process Type window, open the Split Cutouts tab and

place a check in the Lengthen Lead-In to split cutouts

and/or other check boxes as in the image -

|

|

Min Width |

Enter a value

to control the minimum

size that the system will split in half. Any cutout that is smaller

than this value will remain uncut.

To ascertain

the size of cutouts use options on the Dimensioning

menu.

Note: Generally

a cutout that is one inch or smaller doesn’t need to be split,

as it will easily fall between the workchute rollers.

|

Max Width |

Enter a value

to control the maximum

size that the system will split. Any cutout larger than this value

will remain uncut. Larger cutouts should be split, so choose a

value that takes in to account the largest cutout on the part.

Note: If

the cutout is not a standard shape (irregular), then the overall

bounding width (in X) of the rectangle is used to determine if

that cutout should be split or not.

|

Slug Destroy Pitch |

Enable

the checkbox and enter a value to destroy internal cutout slugs

as in the illustration. This option may be used together with

Lengthen Lead-In. This option also takes effect when Fast

Cutting.

Note:

Length and angle values for lead-ins and lead-outs (if used) on

internal cutout slugs are pulled from the Lead In / Lead Out section

on the Split Sheet tab. To avoid

cutting into the part itself, be sure to check the length and

angle values for the lead-in/out carefully!

|

Do not pierce near edge |

To avoid

having the program pierce a cutout on its edge, check this box.

1)

The pierce will begin at the center of the cutout (a lead-in property

may be enabled in Split Sheet),

move down in the Y towards the edge of the cutout and stop short

of the perimeter (by a distance which equals the internal lead-in

geometry length).

2)

A second cut (no pierce) moves up in the Y and stops short of

the perimeter (distance equals the beam diameter value).

3)

The last cut pierces near the bottom (lead-in

may be applied) and then finishes cutting out the slug along the

cutout perimeter.

Note:

Slug Destroy Pitch must be switched on for this feature to work.

|

Remove Slug Destroy when

Microjoints are Present |

When

this is checked ON, if the system detects microjoints on a cutout,

it will bypass the microjoints and leave them intact and functional,

while cutting out the remainder of the slug.

|

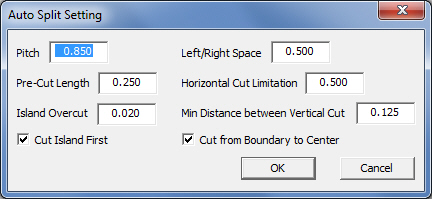

| Auto

Split Setting |

|

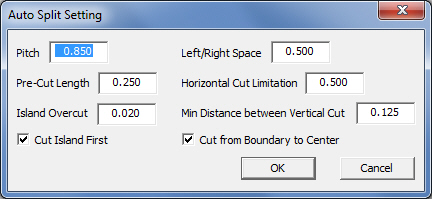

The

Auto Split Setting dialog shown here is identical to the one accessible

by clicking the gear icon on the Cut Sequence>Split Cutouts

submenu.

|

|

Note: Options outlined

in this dialog are generally used for

lightweight materials (ex: aluminum, 20 gauge or less) and

allow the user to place very small and precise split cuts.

|

|

Pitch: This controls the distance

between splits in the cutout.

Left/Right Space: Distance from

the edge of the hole on both left and right sides of the cutout.

Pre-Cut Length: Very thin gauge

materials sometimes require a centrally located vertical precut

before other vertical cuts can occur.

Horizontal Cut Limitation: This

option is used when there are vertical split lines, which have

been cut into smaller line segments. If the lengths of the vertical

cuts are shorter than the user-entered value, horizontal pitch

cuts between vertical cuts will not be cut.

Island

Overcut: This value controls

the size of the overcut when cutting the remaining boundary on

an island. It takes affect only when Cut Island First is checked ON.

Min

Distance between Vertical Cut: This

value is the minimum distance between the vertical boundary and

the split line in the vertical direction.

Cut Island First: If an island

exists on the part, the system will cut it out first. Check the

box ON to enable this option.

Cut from Boundary to Center:

If pre-cuts have already been cut, full cuts will start at the

edge of the hole and move toward the center.

Click

OK to save or Cancel

to close out the dialog without saving any changes. |

|

|

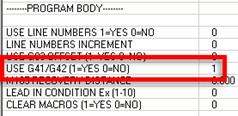

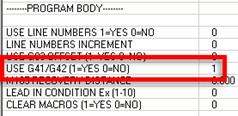

Beam

Compensation

|

Use value from Mat. File |

The value in

this read-only field is entered in the Pierce

Location>Cutter Compensation fields. This option is

typically selected when the G41/42 code is switched OFF (0) in

the CNC Code panel,

because the user requires more control over the cutout. Be sure

to specify exact values to ensure accurate cuts.

|

Use Custom value |

Enter a value here

for Beam (width) Compensation. Use this option when the G41/42

is switched ON (1), which allows the system to automatically calculate

beam compensation.

Note: The

driver divides the entered value in half and adds or subtracts

it from the actual geometry.

|

|

Further Notes:

This

function only applies to paths that cut on the in-side; If

there is Microjoint on the cutout, the system will not split

the cutout; This

function does not apply if another part is nested within the

cutout; Split

Cutouts cuts from the downside to up, so the pierce location

will be at the bottom of the cutout.

|

|

|

To save and

apply changes click the Apply

or Apply All button at the bottom of the Material

Information window (Hot Key: F6) and then OK.

|

|

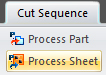

Back in the

work area, you may need to click Process

Part/Sheet on the Cut Sequence menu, to refresh the view

and include any new changes.

Note: Processing

resets the cutting sequence for the selected part or sheet.

|

|

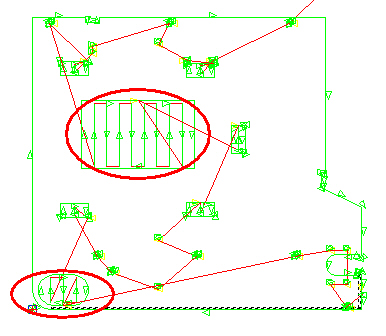

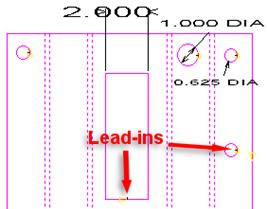

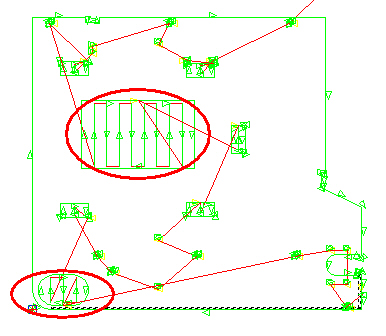

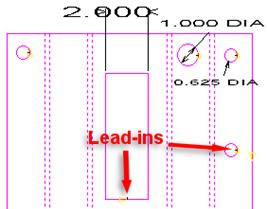

A view

of the part before Split Cut-outs

is enabled.

Notice that the Lead-ins are

visible

on each pattern. |

|

|

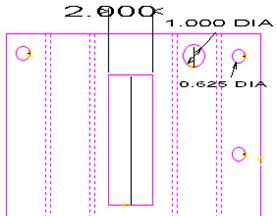

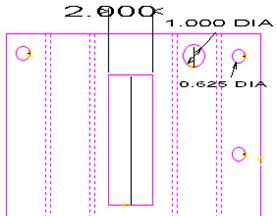

A view

of the same part after Split Cut-outs is enabled. The lead-ins

on two patterns have been lengthened according to user specifications.

Max

Width for

the cutouts was given as 2, so the two larger cutouts have been

included.

Min

Width was

specified as 0.7, so the smallest holes were ignored. |

|

|

|

|

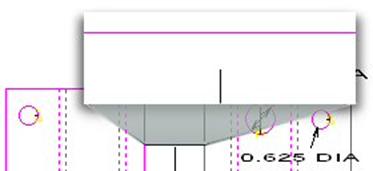

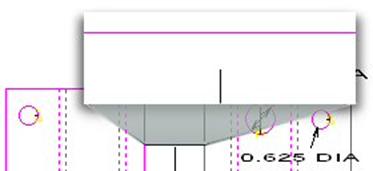

The close-up

here shows the lengthened lead-in and the gap created by the beam compensation,

which was set at 0.1. |

|

|

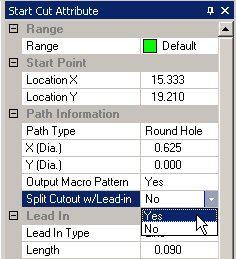

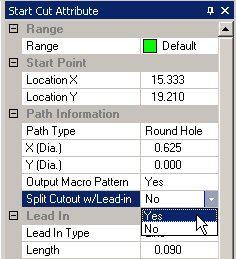

Enable

through Start Cut Attribute panel |

|

Users may also

enable this feature manually by going to Sequence

Features>Start/End Cut Attribute>Start Cut Attribute

and then selecting a pattern in the work area.

Individual

cutouts on separate patterns on a part or sheet can be switched

on or off here.

Changing

a Split Cutout through this panel does NOT automatically update

the settings in the Split Cutouts tab.

|

|

|

|

| |

|

|