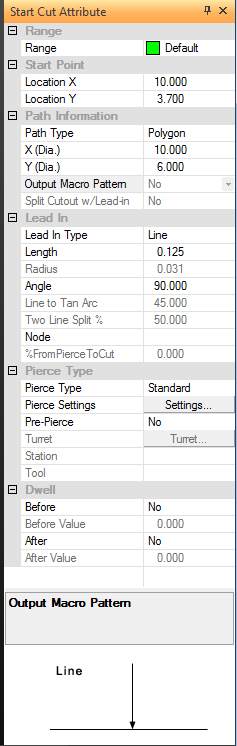

Option |

Description |

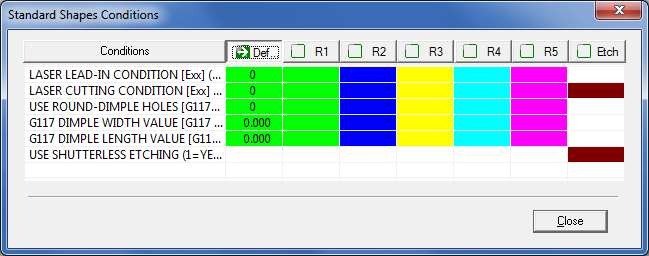

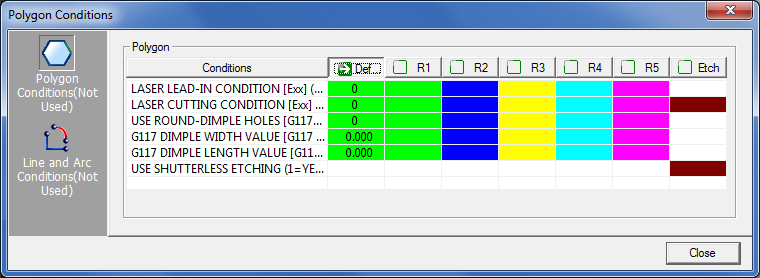

Range |

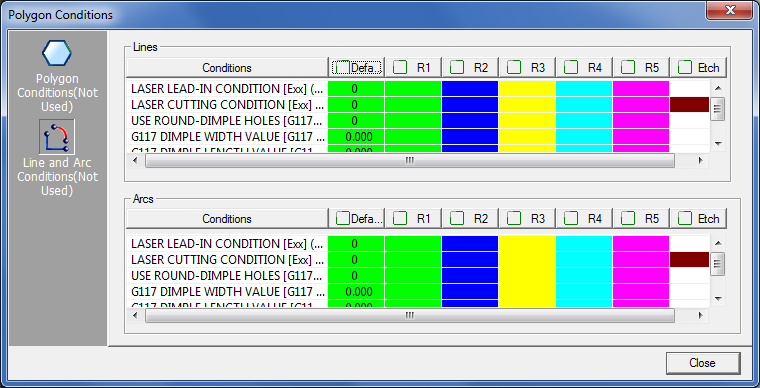

The Range option in the Range

section allows you to display the conditions assigned to the specific

patterns. Double-click the Range label or the navigation button

to open the Polygon Conditions window. |

Range |

Start

Point |

If you want to modify the

actual coordinates for the start point, click either the Location

X or Location Y labels in the window to activate the New Location

buttons. Click the New Location button and move into the work

area. As you move the selected start point around the path, the

values in the Location X and Location Y fields update to indicate

the new coordinates. |

Location

X |

The X coordinate for the

start point. |

Location

Y |

The Y coordinate for the

start point. |

Path

Information |

The Path Information section

of the window displays the path type and size that you have selected

for editing. |

Path

Type |

This field displays the selected

path type, i.e., Round Hole, Rectangle Hole, etc. |

X

(Dia.) |

The X dimension or diameter

of the path. |

Y

(Dia.) |

The Y dimension or diameter

of the path. |

Output

Macro Pattern |

This option allows you to

change the macro status for the path. The status is either True

or False. If you select True from the drop-down list, software

will output macro code for the pattern. It also determines the

conditions and ranges to apply to the path. The range data is

extracted from the material file. |

Split

Cutout w/Lead-in |

Choose Yes to enable the

Split Cutouts option,

which lengthens existing lead-ins to split a cutout in half so

that it can drop safely between the workchute rollers. |

Lead

In |

The Lead In section of the

window allows you to view and edit the lead-in properties for

the start cut attribute. |

Lead

In Type |

You can change the Lead-In

type by selecting Line, Two Line, Line and Arc,

Hook, Cross Cut or None from the drop-down

list. Make sure to specify the appropriate values for the selected

lead-in using the Length, Radius, Angle and

Line to Tan (Tangent) Arc fields. |

Length |

Use this field to specify

the length of the lead-in line. |

Radius |

Use this field to specify

the arc radius of the lead-in line. |

Angle |

Use this field to specify

the angle of the lead-in line. |

Line

to Tan Arc |

Use this field to specify

the tangent arc value. |

Two

Line Split % |

Use this field to specify

the split percentage for the Two Line lead-in. |

Node |

Use the Node option to specify

a cutting condition. |

%

From Pierce To Cut |

Type a percentage value for

the cutting condition node. |

Pierce

Type |

The Pierce Type section of

the window allows you to specify the pierce type and pierce parameters

for the start cut attribute. |

Pierce

Type |

Select the desired pierce

type from the drop-down list: Standard, Shutterless, Power, Quick,

Peck, Power, Other or Pre-Punch. See

Pierce Type in Material Files. |

Pierce

Settings |

You can use this option to

view the current pierce settings for the start cut attribute. |

Pre-Pierce |

This option allows you to

change the pre-pierce status for the path. The status is either

True or False. If you select True from the drop-down list, the

system sequences a pre-pierce hole for the selected path. |

Turret |

If you select Pre-Punch as

your pierce type, you can use the Turret option to designate a

tool in the turret as a pre-punch tool. |

Station |

This field displays the station

number of the designated pre-punch tool in the turret. |

Tool |

This field displays the tool

type and size of the designated pre-punch tool in the turret. |

Dwell |

The options in the Dwell

section of the window allow you to specify a dwell before, after

or before and after the pierce. |

Before |

This option allows you to

change the dwell status before the system pierces the material.

The status is either Yes or No. If you select Yes from the drop-down

list, the system will insert a pause code before the actual pierce

command. |

Before

Value |

Use this field to specify

the actual dwell time in seconds. |

After |

This option allows you to

change the dwell status after the system pierces the material.

The status is either Yes or No. If you select Yes from the drop-down

list, the system will insert a pause code after the actual pierce

command. |

After

Value |

Use this field to specify

the actual dwell time in seconds. |

Node

Display |

This panel displays the currently

selected cutting conditions. |

Lead

In Type Display |

This panel provides a graphical

display of the currently selected lead-in type. |

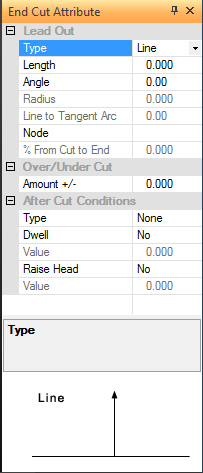

The End

Cut Attribute flyout window functions much like its counterpart,

the Start Cut Attribute window. It allows you to view and modify

the end point information for a path. You can modify the lead-out

properties, view the currently assigned condition range value,

specify overcut and undercut amounts and after cut conditions.

The options found in this window function like their counterparts

in the Lead In/Lead Out and Pierce Location folders of the Material

Information window. See Material Files. |

|

Option |

Description |

Lead

Out |

The Lead Out section of the

window allows you to view and edit the lead-out properties for

the end cut attribute. |

Type |

You can change the Lead-Out

type by selecting Line, Arc, Line and Arc,

or None from the drop-down list. Make sure to specify the

appropriate values for the selected lead-in using the Length,

Angle, Radius and Line to Tan (Tangent) Arc fields. |

Length |

Use this field to specify

the length of the lead-out line. |

Angle |

Use this field to specify

the angle of the lead-out line. |

Radius |

Use this field to specify

the radius of the arc. |

Line

to Tan Arc |

Use this field to specify

the tangent arc value. |

Node |

Use the Node option to specify

a cutting condition. |

%

From Cut to End |

Type a percentage value for

the cutting condition node. |

Over/Under

Cut |

The Over/Under Cut section

of the window allows you to specify the extent of the overcut

or undercut. |

Amount

+/- |

The default value is zero.

If the value is zero, the cut ends where it started. If you type

a positive value, the cut extends beyond the starting point. Conversely,

if you type a negative value, the cut stops short of the starting

point. |

After

Cut Conditions |

The options in the After

Cut Conditions section allow you to add code to the program after

each cut. |

Type |

There are three options on

the drop-down menu: None, Program Stop and Optional

Program Stop. Select None if you do not wan the system

to stop after each cut. Select Program Stop to output a

program stop. Select Optional Program Stop to output an

optional program stop. |

Dwell |

The Dwell option allows you

to specify a dwell after the cut. The status is either Yes or

No. If you select Yes from the drop-down menu, the system will

insert a pause after the cut. |

Dwell

Value |

Use this field to specify

the actual dwell time in seconds. |

Raise

Head |

The Raise Head option allows

you to raise the cutting head after the cut. The status is either

True or False. If you select True from the drop-down menu, the

system will raise the head to the preferred head-up height of

the machine unless you specify a raise head value in the field

below. |

Raise

Head Value |

Use this field to specify

the actual head-up height that you want to use after a cut. |

Option

Display |

This panel displays the currently

selected End Cut Attribute option in the window. |

Lead

Out Type Display |

This panel provides a graphical

display of the currently selected lead-out type. |