Fast Laser

Cutting

What

is Fast Laser Cutting?

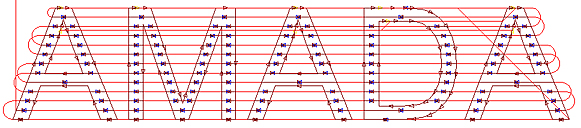

Using Fast Cut is like choosing to drive

on a freeway rather than on surface streets. Streets have so many stops

that

a driver can never attain the speed limit, but on the freeway a driver

can achieve and maintain the highest speed possible.

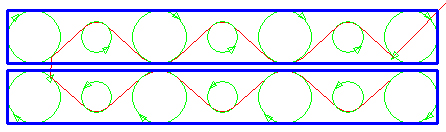

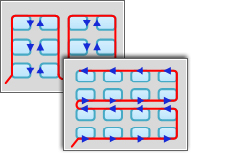

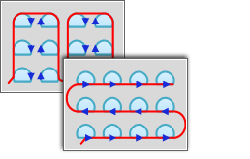

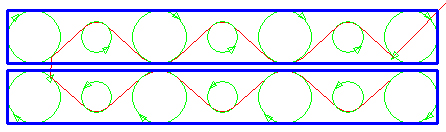

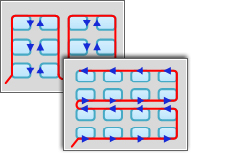

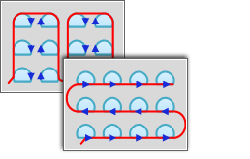

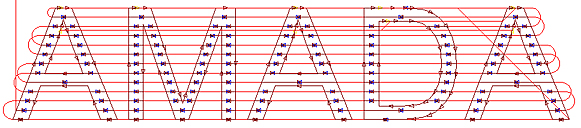

Usually

a laser head completely cuts out one pattern before moving on

to the next. But Fast Cut smoothly continues laser head motion

as though cutting out a figure 8. The laser head, moving in continuous

half-circles, cuts out the top of the first round (#1); the beam

then pauses while looping in a half-circle between patterns around

the lower half of the 8 (#2).

When

the laser head comes to the second round (#3), it powers up again,

cuts the top half, loops under #4 and continues in this way until

the upper half of all the rounds are cut (#5). Fast Cut then continues

around the last pattern to cut out the bottom halves (#5).

Entire

pattern groups can be cut in this manner, drastically reducing

overall laser cutting time. |

|

|

Note: The option

is only available for AP100US Premium users. Ask your sales consultant

for more information.

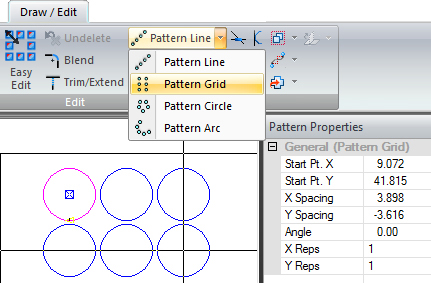

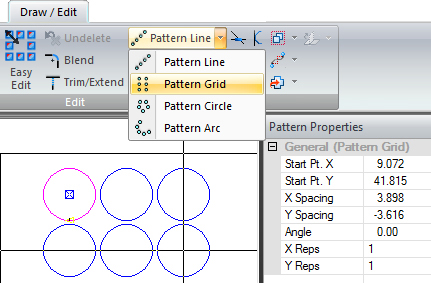

Create

a Pattern Grid

A good way

to begin is by dragging out a grid of similar patterns using options on

the Draw / Edit tab. The image here shows that one Round pattern was drawn

on a part and then the Round was gridded into a pattern using Pattern

Grid on the Draw / Edit menu. After the grid is placed the user

may then make adjustments in the Pattern

Properties pane. The user may first create a grid of patterns and

use Fast Cut directly on the grid, or if need be the grid may be Exploded,

because Fast Cut also works with patterns that are ungridded or ungrouped.

See Draw>Draw

Patterns and Edit>Edit Patterns

for more info. See also Cut

Sequence tab>Fast Cut on how to enable this feature from the AP100US

interface.

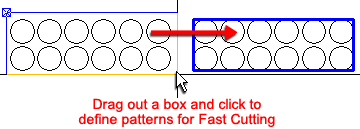

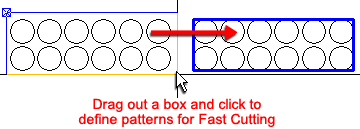

Define

Fast Cut

To define a

Fast Cut, the user must manually define a group of patterns by selecting

the Define Fast Cut option and then dragging out a box to enclose the

patterns to be Fast Cut. See the Cut

Sequence>Fast Cut options on the Cut

Sequence tab.

When this is done the system recognizes the pattern

shapes and applies the default Round pattern option set.

The user may

then select the specific type of Fast Cut by toggling through the option

buttons in the Fast

Cut Settings mini-window and choosing a different Round Hole option.

The program will then dynamically change the sequencing of the pattern.

Only patterns

that have been Fast Cut defined will be cut out using Fast Cut. All remaining

patterns will be bypassed, and the program will sequence these "undefined"

patterns according to default settings.

Different Pattern Sizes with Same Center

Point

Pattern groups may contain patterns of different sizes, but if they share

center-points that are in one line they can be defined and cut by Fast

Cut.

If

part sizes differ the program will default to inner-tangent

Fast Cutting regardless of the option selected by user

Notes:

Fast Cut focuses on smaller patterns that are nearer together. A grid of

larger patterns that are spaced farther apart may not be definable by

Fast Cut.

The Fast Cut

submenu will not display when a Combo machine is loaded.

Fast Cutting does not use lead-ins (except for the first pattern) or piercing.

Fast Cutting functions in both Part and Sheet views.

Amada

recommends these material specifications for Fast Cutting:

For 2kW & 3kW machines: Mild steel – Up to 1.6 mm. Stainless Steel

-1.0 mm. Aluminum -1.0 mm.

For 6kW or 9kW Amada FOL AJ or LCG AJ machines materials up to 12 gauge

can be Fast Cut.

Selecting

Fast Cut Options

Options chosen

will give results that can differ according to many different variables,

such as operator experience and machine characteristics when cutting a

certain arrangement of patterns/parts on a sheet. This section is intended

to serve as general guidelines.

The user may

view instructive Demo Videos for the

Fast Cut feature, in addition to other New Enhancements in this release.

|

|

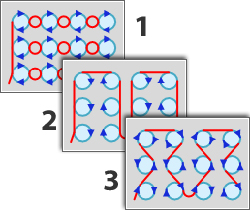

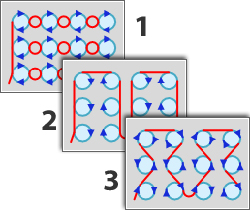

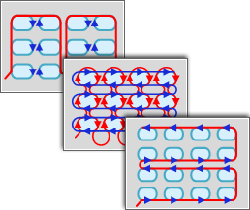

Round Hole Fast Cut Options

Sequence

1: Round hole with Arc tangent. Use with Amada's FOL Laser Machine.

Sequence

2: Round hole with Line tangent. Use with Amada's FOL Laser Machine.

Sequence

3: Arc and Line tangent. Use with Amada's LCG Laser Machine. Use

this option in conjunction with Area Fast Cut when ungridded (exploded)

Round patterns of different sizes are on a part.

Note:

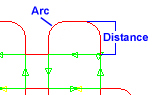

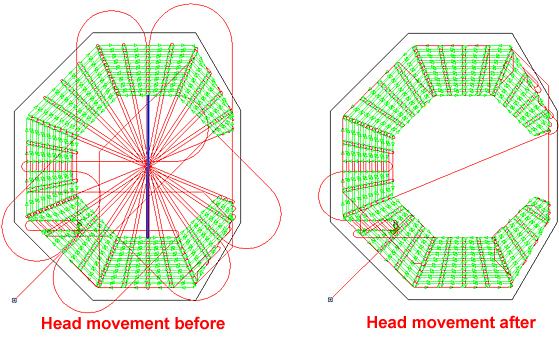

The red lines indicate laser head movement between patterns when

the laser is powered OFF. The laser head retains the same distance

from the part throughout the process. The laser head will loop

between patterns wherever the distance between patterns is less

(noticeable especially in Sequence 1).

|

|

|

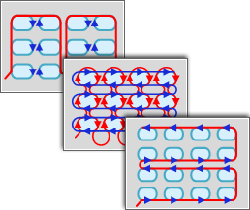

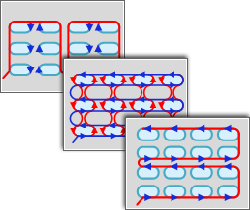

Double D Fast Cut Options

Sequence

1: Line tangent. Use with Amada's FOL Laser Machine.

Sequence

2: Arc and Line tangent. Use with Amada's FOL Laser Machine.

Sequence

3: Line tangent. Use with Amada's LCG Laser Machine.

|

|

|

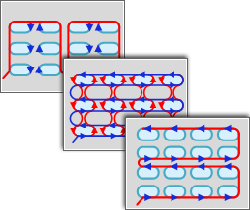

Obround Fast Cut Options

Sequence

1: Obround with Line tangent. Use with Amada's FOL Laser

Machine.

Sequence 2:

Obround with Arc tangent. Use with Amada's FOL Laser Machine.

Sequence 3:

Obround with Line tangent. Use with Amada's LCG Laser Machine.

|

|

|

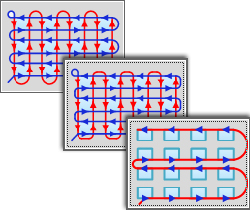

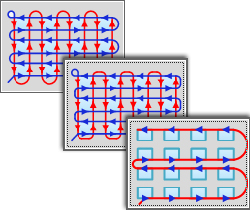

SQ/RE Hole Fast Cut Options

Sequence 1:

Square with Line tangent. Use with Amada's FOL Laser Machine.

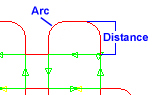

Sequence 2:

Square with Arc tangent. Use with Amada's FOL Laser Machine. With

this option Arc Radius and Distance values may be entered to avoid

conflicts with adjacent patterns.

Red line indicates

laser head movement

Sequence

3: Square with Line tangent. Use with Amada's LCG Laser Machine. |

|

|

Rounded Corner Hole Fast Cut Options

Sequence

1: Single D. Use with Amada's FOL Laser Machine.

Sequence

2: Rounded Corner Hole. Use with Amada's LCG Laser Machine.

|

|

|

Single D Fast Cut Options

Sequence

1: Single D. Use with Amada's FOL Laser Machine.

Sequence 2:

Rounded Corner Hole. Use with Amada's LCG Laser Machine.

|

|

|

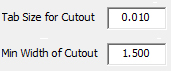

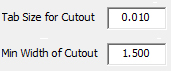

Use these

options to place a [microjoint] tab on cutout corners to prevent

loose cutouts from tilting and causing a collision or other stoppage.

Enter

a size for the tab on a cutout. A default of 0.010 is given, but

the user may adjust this as needed.

Enter

the minimum width of cutouts to be tabbed. If the cutout is smaller

than 1.5 (default), there is no need for a tab because a small

cutout should drop harmlessly from the table. User may adjust

this value as needed.

|

|

|

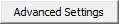

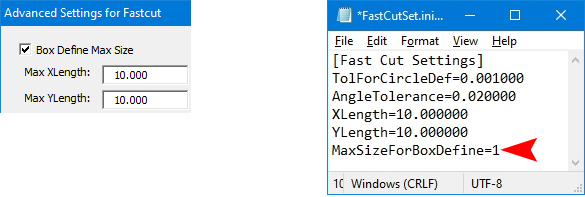

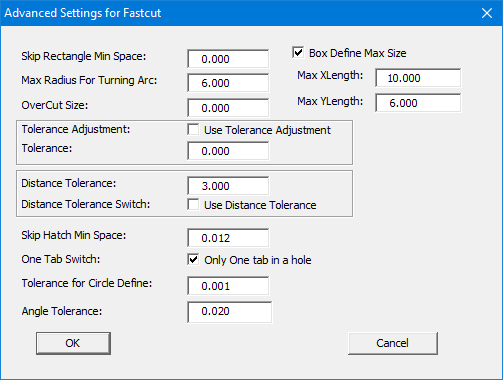

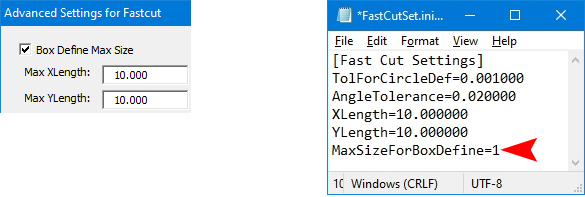

Click

Advanced

Settings to open the window shown here - |

Values entered here are passed to the C:\AP100US\Parm\FastCutSet.ini

file

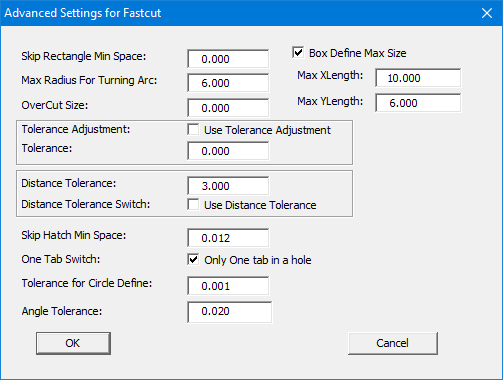

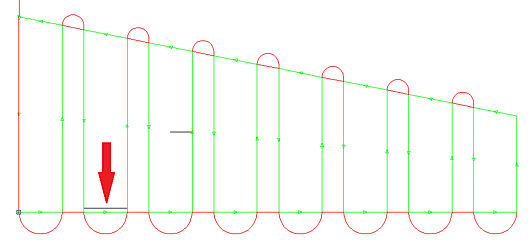

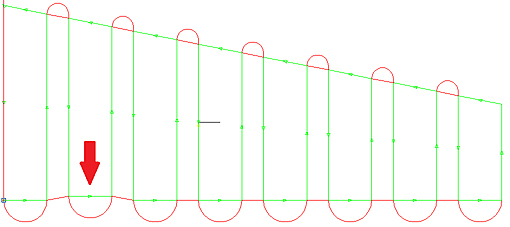

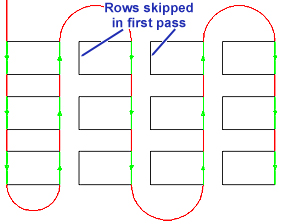

Skip

Rectangle Minimum Space

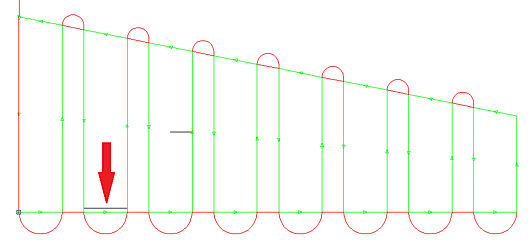

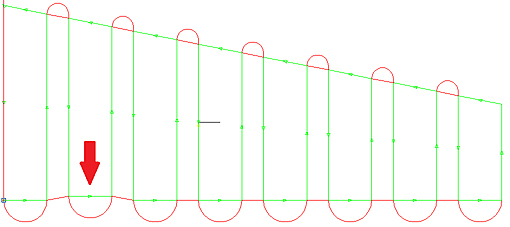

Using Fast Cut when distances between patterns are very close causes the

head to slow down between rows and also creates a lot of heat on the part

(for example, when etching bar codes on parts). To counteract these problems,

the user can enter a value in the Skip

Rectangle Minimum Space field to enable the “skip” option.

Distances in

X/Y between patterns that are equal to or smaller than the value entered

will be skipped by the program. When Fast Cut finishes the first pass,

it will return again to cut the skipped rows, but in reverse order. This

allows a steady laser head movement to be maintained, while allowing rows

to cool off after being cut.

Skip Fast Cutting in the Y direction

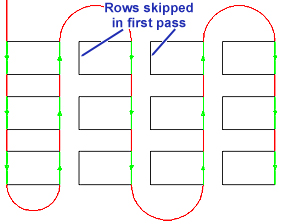

Max

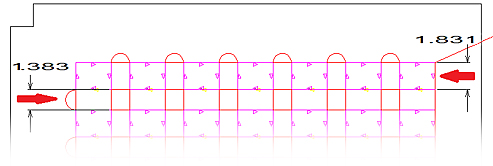

Radius for Turning Arc

When Fast Cut turns to the next pattern using a tangent arc, if the turning

arc is too large laser head movement may exceed the table size. If the

arc is larger than the value given, the system will use a direct line

cut to go to the next point.

For example,

if a value of 1.5 is entered we can see that the distance between lines

on the left is 1.383, smaller than the value entered. This means that

Fast Cut will use an arc. But because the distance on the right is larger

than 1.5, Fast Cut will turn the arc using straight lines.

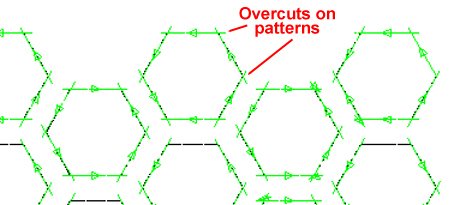

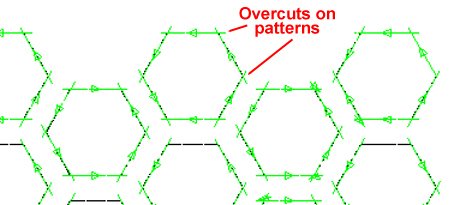

OverCut

Size

The purpose of this option is to make sure that a cutout has been fully

cut and will easily drop from the sheet. The option will make an oversized

(longer) cut, based on the value set in the OverCut Size field.

Box Define Max Size

Define the maximum length

of a Defining box in X and Y. The user must enable the option in the C:\AP100US\Parm

folder by placing a "1" as indicated.

Note:

Based on the Max values entered for Fast Cut boxes, the system will coordinate

and even out the size of each box for a neater sheet.

Tolerance

When Fast Cut is cutting a group of patterns,

if one line is a little “off” (maybe longer or shorter) it will be ignored

by Fast Cut. After the patterns have been cut, the system will then have

to send the laser head back to make that one cut. There are two methods

to resolve this -

Tolerance

Adjustment - Use Tolerance Adjustment

If the user checks ON the Use Tolerance Adjustment switch and also enters

a value in the Tolerance field, if the lines are within the given tolerance,

the pattern will be adjusted in the X or Y direction to make sure it is

in the same line along with the other patterns.

Fast Cut straightened out (moved) the

uneven line and made an even cut

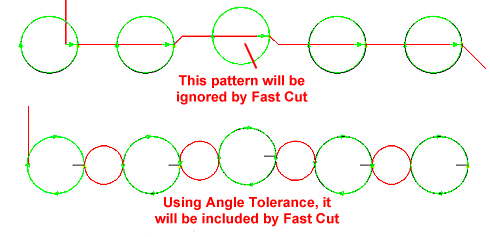

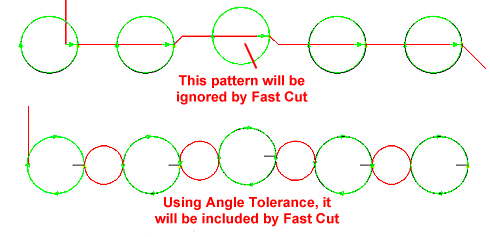

Tolerance

Tolerance allows Fast Cut to adjust the cutting line, to include an uneven

line in the fast cut as in this image. To enable enter a tolerance value

in the Tolerance field. The Use Tolerance Adjustment checkbox should be

switched OFF for this option.

Notice that the uneven line indicated by the

red arrow was included in the Fast Cut

Distance

Tolerance

If the distance

of the trace line for Fast Cut is very large, the head movement may take

up too much time when fast cutting. In order to resolve this problem,

add a distance tolerance value. If the distance between patterns is greater

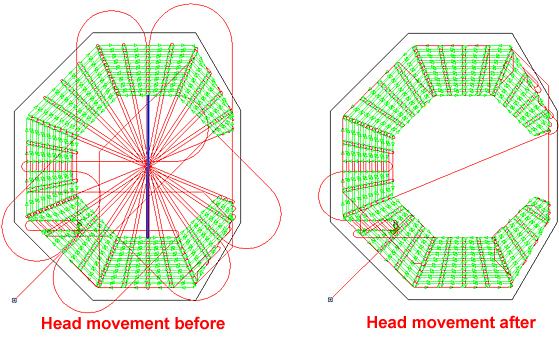

than the given Distance Tolerance value, then Fast Cut will not be enabled.

In the image on the left the system is trying to Fast Cut the entire array

of patterns; notice the amount of head movement. The image on the right

shows how much head movement was decreased after enabling this option.

Distance

Tolerance

A large Distance Tolerance value allows Fast Cut to cut an array of patterns

as one cut, but the head movement may take up too much time. Entering

a smaller value allows Fast Cut to divide the pattern array into several

manageable sections, thereby controlling head movement.

Distance

Tolerance Switch

To enable Distance Tolerance, check ON the Use Distance Tolerance checkbox.

Skip

Hatch Minimum Space

This option allows Hatch Etching and Fast Cut properties to be used together.

If the value in Skip Hatch Min Space is larger than the Hatch Interval

value set in Hatch Etching, Fast Cut will

skip the next hatch etch line and cut the line after that one instead.

Since the distance

between patterns when using the Hatch Etching

option is also very close, the skip method can make the cutting speed

faster and is good for heat dissipation. If the value in “Skip Hatch Min

Space” is larger than the Hatch Interval value set in Hatch Settings,

Fast Cut will skip the next hatch line and cut the line after that one

instead (similar to Skip Rectangle Min Space above).

One

Tab Switch

If this option is checked ON, Fast Cut will leave only one tab in a cutout.

With the option checked OFF, the program may add several tabs in one cutout.

This option works in conjunction with the Tab Size for Cutout and Min

Width of Cutout value fields shown above.

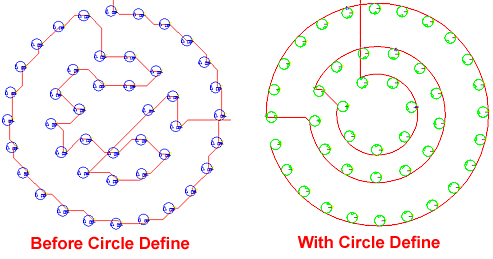

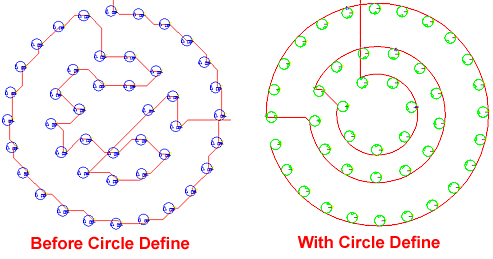

Tolerance

for Circle Define

When defining a pattern circle, Fast Cut will attempt to place patterns

in a group. To do this, a circle center point or points between patterns

must be identified by the program. Entering a tolerance value means that

Fast Cut will assign a common center point to multiple center points that

are within a certain distance from each other (within the tolerance value).

Center points outside of that distance will be recognized by the system

as separate center points.

Note: Using

a large tolerance value allows the program to regard multiple center points

as one center point. In such cases Fast Cut can only guarantee the accuracy

of the cut on the first pattern - cuts on following patterns may become

increasingly inaccurate (off center).

Angle

Tolerance

Fast Cut will calculate the spacing between patterns. If one pattern is

off center, Fast Cutting will be interrupted. For example, when trying

to define a circle line, Fast Cut will notice that one circle is not directly

in line with the others. To counter this the user may then enter an Angle

Tolerance value, enabling Fast Cut to define all the circles as one line.