![]()

Slug Destroy is a powerful feature that enables the user to specify the slugs that will be destroyed. and set parameters for how the slugs themselves will be cut up.

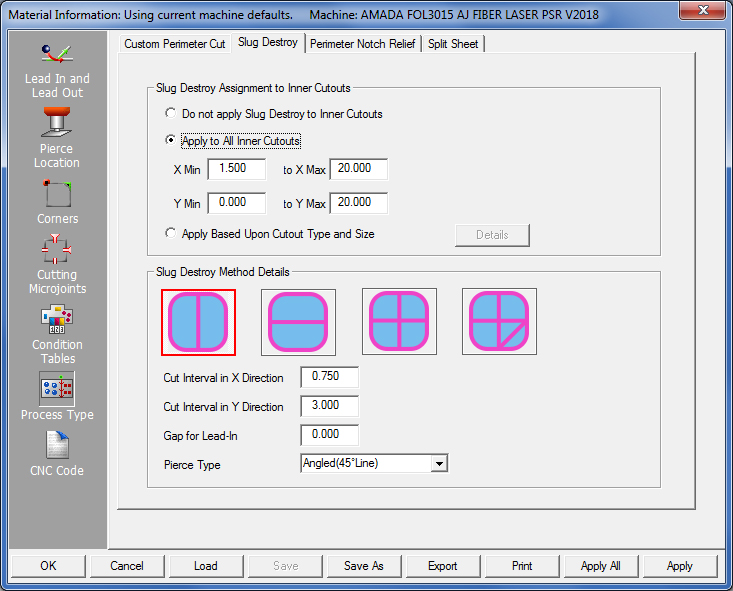

Open this window by going to the System Setting>Edit Material>Process type tab

Note: If Slug Destroy does not appear in the menu tab, enable the option by going to the C:\AP100US\Parm folder and double-clicking the AutoSplitHole.ini file to open it. If the Split Hole Mode is set to 1, enter <0> to switch it OFF and then save the file. Restart the program and Slug Destroy should appear in the menu.

| Slug Destroy Assignment

to Inner Cutouts

This section regulates the overall size and type of patterns that will be targeted by Slug Destroy. Options in this panel can be saved as default settings by clicking the Save button. Clicking OK keeps the settings for the current AP100US session. |

|

| Do not apply Slug Destroy to Inner

Cutouts

Selecting this option will disable Slug Destroy and the option will not be applied to any cutouts. This is the default setting. |

|

| Apply to All Inner Cutouts

Enter Minimum and Maximum size ranges for X and Y. All internal closed loops that fall within the specified size range will be destroyed. Range-checking and validation applies to these text boxes. Values cannot be negative. Max size for cutouts in X is set to 3.0, so the 4.0 Round Pattern was ignored |

|

| Apply Based Upon Cutout Type and

Size

The user may select which pattern types and sizes Slug Destroy will be applied to. Select the option and then click the Details button to open the Slug Destroy by Cutout Type - Details window, shown here -

Irregular Cutout includes non-standard shapes and special tools. |

|

Slug Destroy Method Details

This section gives the user fine control over the slug destroy cuts and the size/shape of slug scraps that will be created. The size of slug scraps will never exceed the value entered by the user. However, the program will determine and adjust the width and quantity of Slug Destroy cuts, so that the fewest number of cuts will be made.

|

Vertical Slug Destroy will

make slug destroy cuts in the vertical. This option is

useful

for making cutouts fall through the Cutting Plate (for sheet-draggers

such as Pulsar, EML & LCC1). This will make a series of vertical

Slug Destroy Cuts, with the final Slug Destroy Cut continuing

on to cut out the perimeter of the Inner Loop. Enter a

Max

Slug Size - X Direction to

control spacing between vertical cuts.

|

|

|

|

Horizontal Slug Destroy will make slug destroy cuts in the horizontal. This will make a series of horizontal Slug Destroy Cuts, with the final Slug Destroy Cut continuing on to cut out the perimeter of the Inner Loop. Enter a Max Slug Size - Y Direction to control spacing between horizontal cuts. |

|

Grid Slug Destroy This will make a series of horizontal and vertical Slug Destroy Cuts, with the final Slug Destroy Cut continuing on to cut out the perimeter of the Inner Loop. Enter a Max Slug Size in X & Y Direction to control spacing between horizontal cuts. | |

|

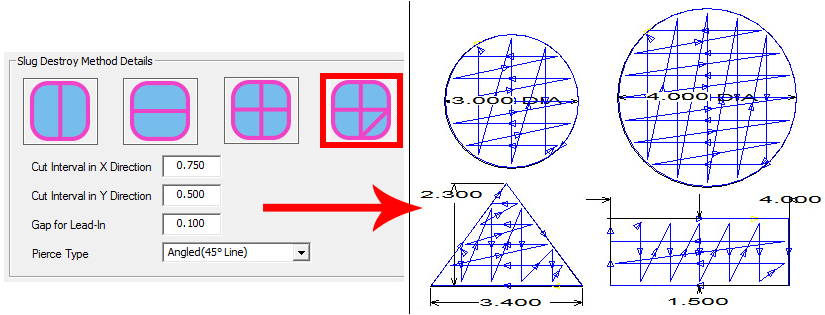

Continuous Slug Destroy will also make slug destroy cuts in a grid pattern, but when applying the method, the base assignment pattern begins with grid lines and then connecting cuts are added to make the cutting continuous. Note: When Continuous Cutting is applied by software and the "continuous" paths end up cutting across/through "good" sections of the part, then the program will automatically revert to the Grid method. |

Slug Destroy settings on the left give these

results on the patterns

(Gap for Lead-in value has been exaggerated for visual effect)

Cut

Interval in X/Y Direction

For the X direction,

enter a cut interval value (the distance between cuts). For the Y direction,

enter a cut interval value. When using Grid Slug Destroy, enter values

in both X & Y fields.

Gap

for Lead-In

This value allows the

user to fine tune the laser cut lead-in, in order to compensate for beam

diameter and other considerations that are unique to the machine in use.

The software will already compensate the Pierce Location of each

Slug Destroy Cut by the Beam Diameter, if a Beam Diameter value has been

entered elsewhere in Machine Settings. If it is set to 0.000, then

the Pierce will occur directly at the edge of the feature, compensated

solely by the Beam Diameter entered by user.

See Pierce Location panel for more info on Beam Diameter and Lead-In, Lead-Out for more info on Lead-Ins.

Pierce

Type

For the three types

of Lead-ins, the Lead-In length will be the value entered in the Material>Lead In & Lead Out

panel.

At Edge (No Lead-in)

For this pierce type the software will

pierce directly at the Slug Destroy cut line, only compensating for the

beam diameter. If there is a value in "Gap for Lead-In",

then there will be an additional compensation by the amount the user specified.

(ex: .006" Beam Diameter + .010" Gap for Lead-in Value

would result in 0.013" compensation pierce location)

Note: For Horizontal, Vertical, and Grid Methods, the final Slug Destroy cut will continue onwards to complete the cutting of the entire feature.

Angled (45° Line)

This Lead-in type will be a 45° line,

of the same length that the user has defined in the Material>Lead

In & Lead Out panel.

If a collision with the Lead-in is detected into the part, the software will attempt to flip the lead-in by 90 degrees (to the other side of the line, to remove the collision. If a collision cannot be resolved by rotating the lead-in angle, then that Slug Destroy Cut will be an At Edge (No Lead-In) pierce.

From Center Outwards

This Lead-in type will consist of a

central pierce, in the middle of the Slug Destroy Cut Line, and cutting

will occur from this central Pierce Location outwards in each direction

towards the edges of the cutout.

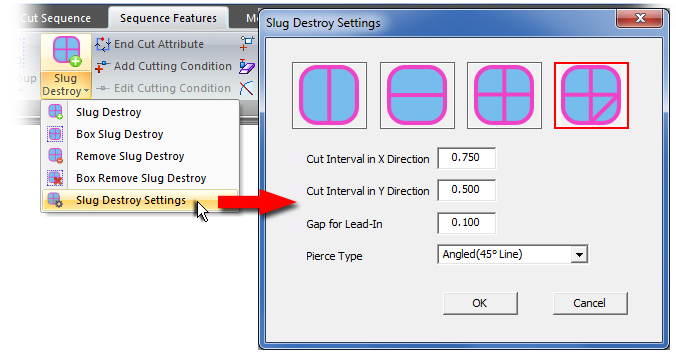

Slug Destroy Settings Mini-window

The main Slug Destroy window & the Mini Settings

window are dynamically linked

Updates done in one Input area will simultaneously appear in the other

Access the Slug Destroy pull-down menu to apply or remove Slug Destroy from patterns on an individual basis while in the work area. Open the mini-window to open a scaled-down version of the settings available in Process Type>Slug Destroy tab.

Note: The Slug Destroy option may be switched OFF, in favor of the Split Cutouts option. See Split Cutouts for more info.