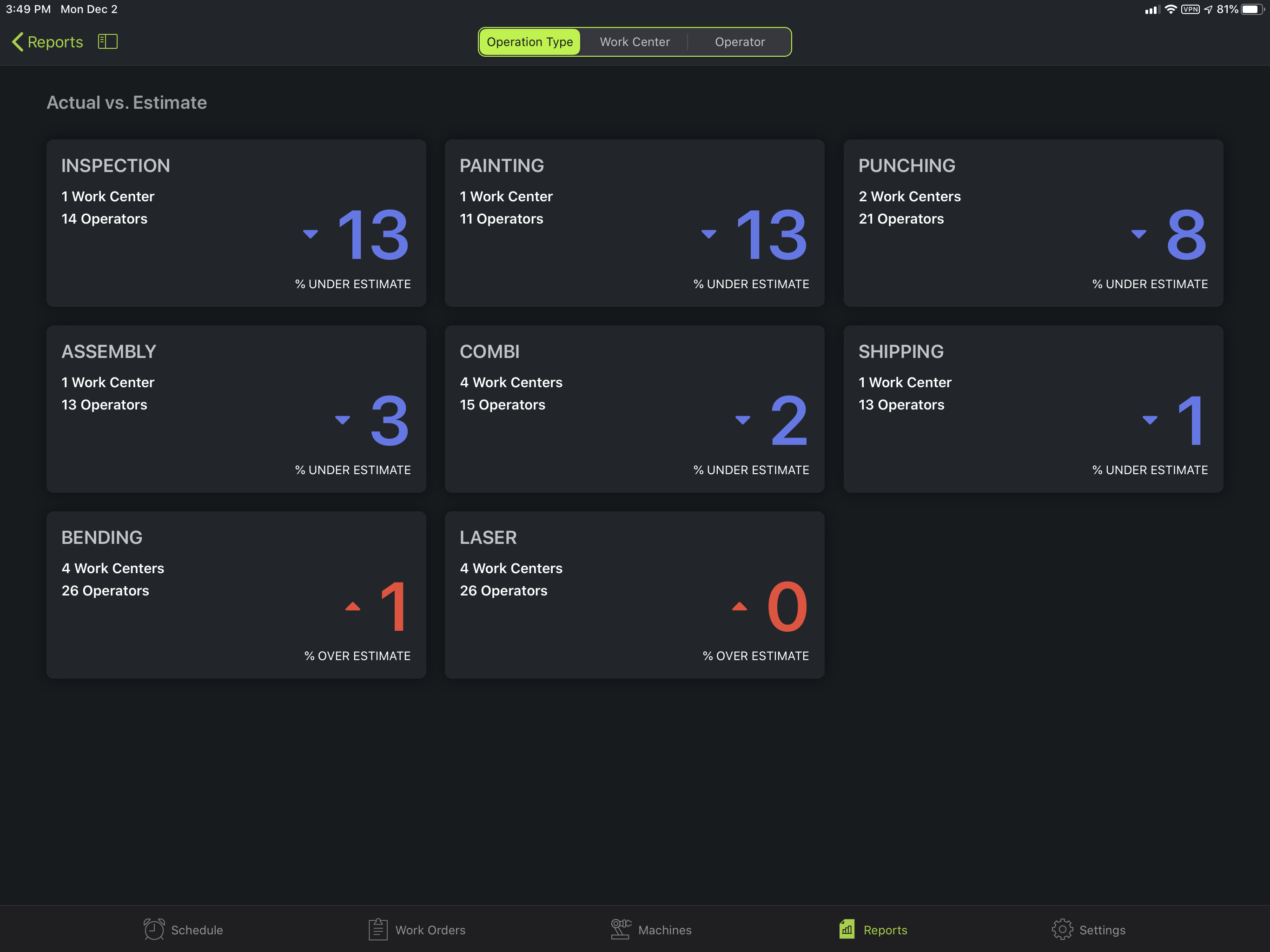

You can analyze quotation accuracy by Operation Type, Work Center, or Operator

which all aid in continuous quote improvement. Since Influent records actual times you can

easily compare these times to the estimates to help refine your quotes.

Provides detailed information about the actual production time at each work center versus the

estimated runtime from the ERP. View the report by Department, Work center, or Operator.