The Runtime Estimate feature will calculate the operating time for patterns, which have an assigned tool. This feature can be used in both sheet and part modes. With Run Time Estimate it’s possible to make decisions based on the calculated runtime. The Run Time Estimate panel also allows machine work chutes and trap doors to be defined and controlled. Some options are available for both Auto Sequence and manual sequencing. Note 1: Certain fields may be disabled, depending upon the type of driver that is loaded. Note 2: If an older Amada driver (previous to 2010) is loaded, the Run Time Estimate icon will not display, and these windows will not be available. Note 3: Only Amada machines can utilize JKA, JKAX, JKF, JKM, JKAM and JKMX files; machines from other manufacturers cannot use these files. |

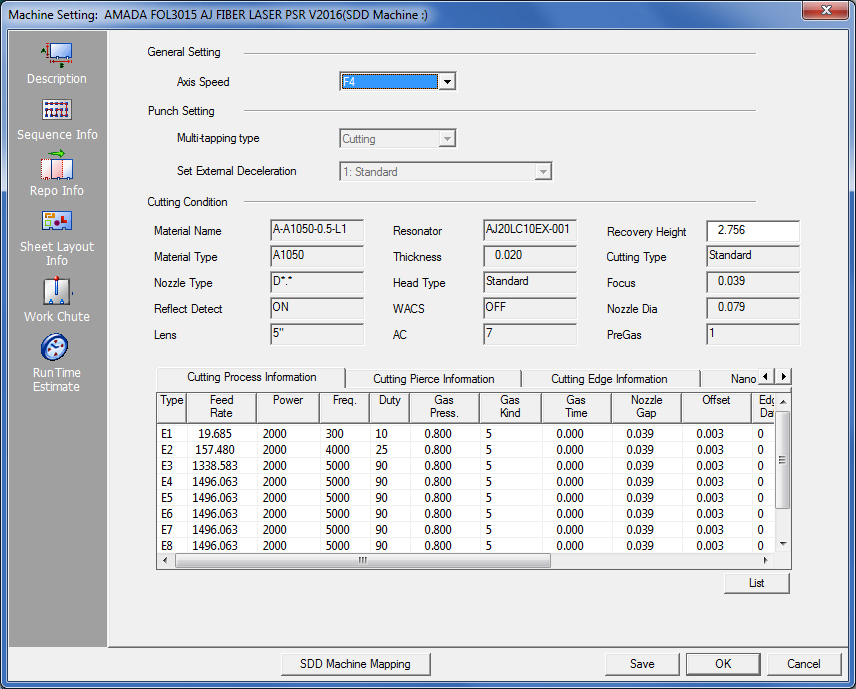

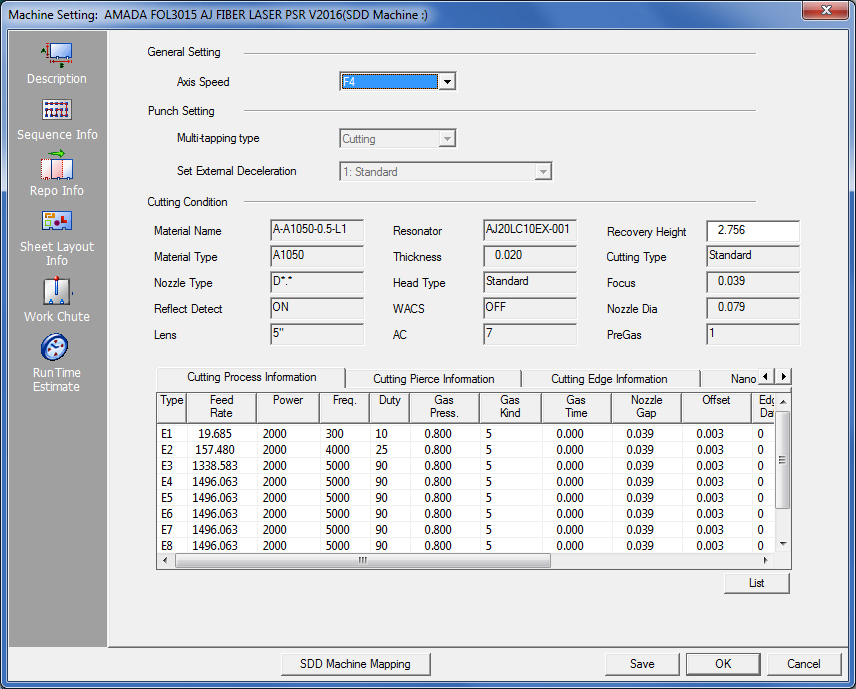

This Run Time Estimate Panel displays for AMADA Laser machines.

Option |

Description |

General Setting |

These options are used for all types of Amada machines. |

Axis Speed |

Select a speed option from the drop-down list to specify the table movement speed. There are four options that range from F1 to F4 (F1 is 100%, F2 is %75, F3 is 50% and F4 is %25). |

Punch Setting These settings are for punching machines. The system will detect when a driver is loaded, and decide if the machine is only for cutting, punching or a combo. If the driver only supports cutting, then the entire Punch Time section will be disabled. |

|

Multi-tapping Type |

Cutting and Forming are included on the list. Select one Multi-tapping type from the drop-down list. |

Set External Deceleration |

Choose an External Deceleration value of 0: None, 1: Standard or 2: The second external deceleration speed from the drop-down arrow. |

Cutting Condition These read-only settings are for cutting machines. The system will detect when a driver is loaded, and decide if the machine is only for cutting, punching or a combo. If the driver only supports punching, then the entire Cutting Condition section will be disabled. See View Cutting Condition Table for Cutting Condition info. Note: For more info on the Cutting Process Info, Cutting Process Info, Cutting Process Info, Nano Joint and Append tabs, please call the Amada Call Center. |

|

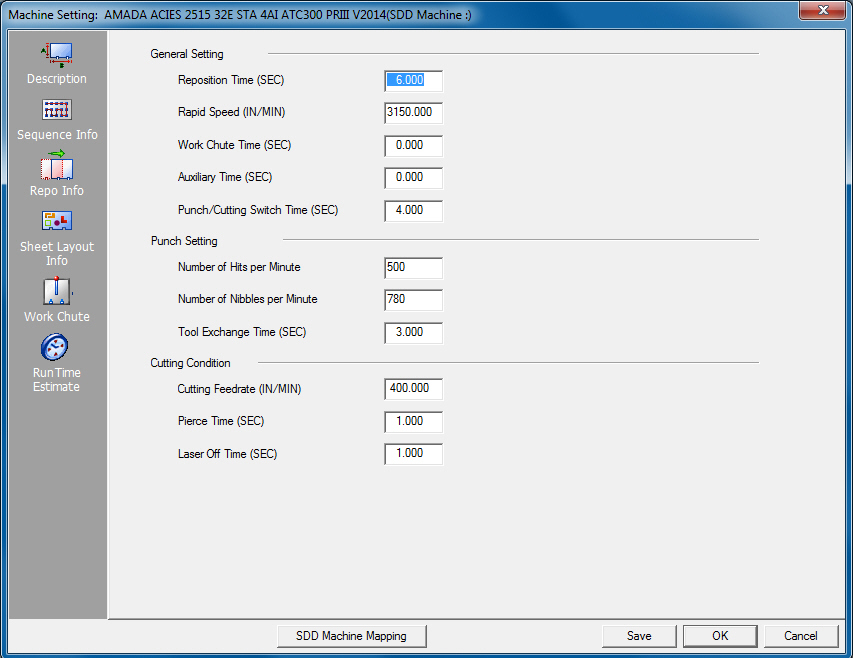

This Run Time Estimate Panel displays for AMADA combo machines.

Option |

Description |

General Setting Input general settings for other than AMADA machines. |

|

Reposition Time (SEC) |

Specify the sheet reposition time here, given in seconds. |

Rapid Speed (IN/MIN) |

Specify the axis speed to calculate the process time, given in inches per minute. |

Work-chute Time (SEC) |

The time that work-chute functions open and close, given in seconds. |

Auxiliary Time (SEC) |

Specify any other additional time not covered by the other options. |

Punch/Cutting Switch Time (SEC) |

For a combination machine; the time necessary for changing the machine. |

Punch Setting These settings are for punching machines. The system will detect when a driver is loaded, and decide if the machine is only for cutting, punching or a combo. If the driver only supports cutting, then the entire Punch Time section will be disabled. |

|

Number of Hits Per Minute |

Specify the quantity of hits per minute to be executed. |

Number of Nibbles Per Minute |

Specify the quantity of nibbles per minute to be executed. |

Tool Exchange Time (SEC) |

Specify the speed used to exchange tools, in seconds. |

Cutting Condition These settings are for cutting machines. The system will detect when a driver is loaded, and decide if the machine is only for cutting, punching or a combo. If the driver only supports punching, then the entire Cutting Condition section will be disabled. |

|

Cutting Feedrate (IN/MIN) |

The feed rate of the cutting condition, given in inches per minute. |

Pierce Time (SEC) |

The time used for piercing, given in seconds. |

Laser Off Time (SEC) |

Specify the laser head off time, given in seconds. The value should be the time required to end the cut. It should be from the time the head reaches the end of the cut to the time when the machine starts moving to the next pierce. |

SDD Machine Mapping |

Clicking this button links the current machine in AP100US to a Machine registered in SDDJ. Data from the programs that have been stored into SDDJ can be linked to other products that link to SDDJ (such as AP100G CAM or Dr.ABE_Blank). Contact Sales Support to learn how to activate the SDDJ Server. Click for complete SDD information. |

Save / OK / Cancel |

Clicking Save after making changes will save those changes as the default. Click OK to save changes only for this session (system reverts to default settings when program is closed). Click Cancel to cancel any changes and close the window. |