Selecting Optimize Start Points on the Cut Sequence menu changes the location of the start points on the part, in order to optimize machine head travel.

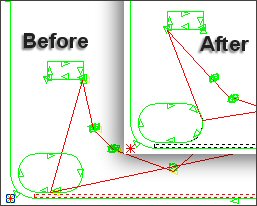

The Before image shows the original trace line (Head Movement of 180.9679) on the corner of a part

The After image shows the optimized trace line with a Head Movement of 177.6640

Optimize Start Points is enabled after the part/sheet has been sequenced. This will not impact the sequence order, as any changes that the function makes are based on the original sequence order.

This function can be used for auto or manually sequenced parts/sheets, after the trace line has been edited and when using subroutines (in Sheet View).

When optimizing start points, the system only considers the previous and next paths, and will not choose a corner as a start point.

Note: This feature is disabled if there is no Sequence on the Part/Sheet.

Compatibility with other AP100US functions:

Compare this feature to Start Point Optimization on the Machine>Sequence Features panel, which generates an optimized sequence from the start.

This option can be used in conjunction with Cutout Avoidance, as the system automatically takes into consideration Cutout Avoidance settings (if enabled) when optimizing start points.

This option only changes the location of the start point; the length and angle are the same as they were originally, except the “Lengthen Lead-In” property is removed. Split Cutouts will also be removed, but can be replaced manually on a part after optimization.

The use of Start Point Optimization will most likely remove macros (if used) and may not give the best Sheet Runtimes if subroutines are used. With subroutines (which control start points) individual part time estimates may improve, but overall sheet time may not be accurate or show noticeable improvement.