![]()

Manual Trace, which is ON by default, allows the laser head to sense the surface of the material (sheet) and maintain a specified distance from the sheet during cutting; this is done to account for uneven sheet surfaces that may disrupt the laser cutting process.

This feature may be switched ON by enabling the Trace off for notch switch in Common Cutting Settings.

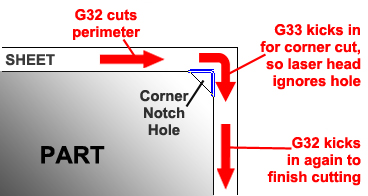

If the laser head encounters part corner notches on the sheet that may have fallen out beforehand, the sensor detects the hole, and the head drops down in an effort to maintain distance from the material, thus causing a collision.

Note: Process Parts/Grids in the Common Cutting sub-menu first to enable the option. Also, check ON Straight Edge Cut in Common Cutting Settings.

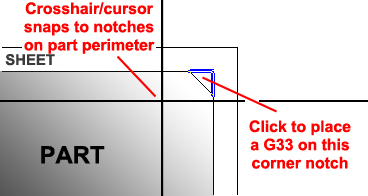

The user must select the Manual Trace off option and then click on parts on the sheet that have corner notches and may possibly have this problem.

The system still continues to cut out part perimeters using a standard G32 (Manual Trace ON), allowing the laser head to sense the surface of the sheet. However, when the laser head approaches a corner notch with a G33 (Manual Trace OFF), the head will ignore the hole in the sheet. After the laser head passes the corner, the G32 will kick in again and the part perimeter will be cut out.

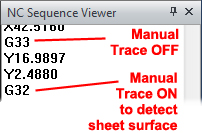

NC View code generated

after sequencing

Click for info on the NC Sequence Viewer.