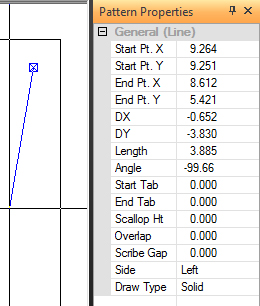

Option |

Description |

General

(Line) |

|

Start

Pt. X |

The X coordinate for the

starting point from the reference point of the part. Edit the

value by selecting the field and typing in a new value. Also,

when the field is hi-lited click the placement button that appears,

move the cursor into the work area and manually place the Start

point in x.

|

Start

Pt. Y |

The Y coordinate for the

starting point from the reference point of the part. Edit the

value by selecting the field and typing in a new value. Also,

when the field is hi-lited click the placement button that appears,

move the cursor into the work area and manually place the Start

point in y. |

End Pt.

X |

The X coordinate for the

ending point from the reference point of the line. Edit the value

by selecting the field and typing in a new value. Also, when the

field is hi-lited click the placement button that appears, move

the cursor into the work area and manually place the End point

in x. |

End Pt.

Y |

The Y coordinates for the

ending point from the reference point of the line. Edit the value

by selecting the field and typing in a new value. Also, when the

field is hi-lited click the placement button that appears, move

the cursor into the work area and manually place the End point

in y. |

DX |

The distance the line moves

in the X direction from its starting point. Edit the value

by selecting the field and typing in a new value. |

DY |

The distance the line moves

in the Y direction from its starting point. Edit the value

by selecting the field and typing in a new value. |

Length |

The overall length of the

line. Edit the value by selecting the field and typing in

a new value. |

Angle |

The angle of the line from

its starting point. Edit the value by selecting the field

and typing in a new value. |

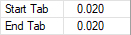

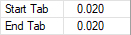

Start

Tab

End Tab |

The Start Tab text box allows

a tab to be specified for the starting point. To place tabs on

a line, move into the property window and edit the values for

the Start Tab (beginning of the line) or End Tab

(end of the line). To shorten the tool path or cutting path (make

the line shorter), use a positive number. To lengthen the tool

path or cutting path (make the line longer), use a negative number.

Note:

It may be best to wait and place tabs on individual part copies

after arranging the sheet. Tabs drawn on one part affect all the

copies made of that part. |

Scallop

Ht |

Type a value in the Scallop

Ht. text box to specify the scallop height for the line. The scallop

height is the distance formed by the scallop created by nibbling

tools. See Pitch/Overlap/Scallop

Info. |

Overlap |

The value in this text box

allows the user to control the distance between tool hits along

the length of the line. |

Scribe

Gap |

Use the Scribe Gap option to control the

pitch between hits for a designated scribe tool. Changes made

here will be reflected in the Tool

Info panel. |

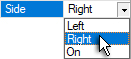

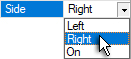

Side |

Change the side of the punched

line while adding or editing a pattern. Move into the property

window and select the Side option of your choice from the

drop-down list: Left, Right or On.

Learn how to use the Change

Line Side option on the Tool menu (punching) or Change Side on

the Cut Sequence menu (cutting) to change the line side after

assigning punch or cutting tools. When shearing or punching a

line, specify which side to cut or punch. When shearing or cutting

around the part in a clockwise direction, the line is processed

on the left side. When shearing or cutting around the part in

a counter-clockwise direction, the line is processed on the right

side. It functions like the positive and negative values of the

NC code; the left side is positive and right side is negative. |

Draw

Type |

The Solid and Construction

options control whether the line appears as a solid line (one

to cut or punch) or a construction line (for bending or reference

only). Construction lines appear as dashed lines. Use a solid

line for cut or punched patterns. |

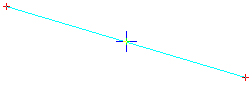

Line

Snap Points |

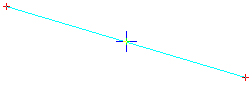

Once a line has been drawn

out, edit by clicking the Edit button.

When a line is ready to be edited, it will have three snap points:

one at the beginning, one in the center and one at the end.

|

![]() Select the Line option on the Draw / Edit tab to create

a line. When prompted, select a starting point and drag with the

mouse to the ending point. As the line is dragged out, notice

how the values update in the Pattern Properties panel. All values

for a line can be edited in the Pattern Properties panel.

Select the Line option on the Draw / Edit tab to create

a line. When prompted, select a starting point and drag with the

mouse to the ending point. As the line is dragged out, notice

how the values update in the Pattern Properties panel. All values

for a line can be edited in the Pattern Properties panel.