Designing

& Defining Special Tools & Cluster Arrays

A

special tool is any tool configured of a non-standard shape. A non-standard

shape indicates the tool is something other than a round, obround, rectangle,

square, single D, double-D, four-way radius, triangle, or rounded corner

rectangle.

Options

on the Tool Assign tab > Special Tool submenu allow you to create

and manage special tools quickly and easily. Once you create a special

or cluster tool and add it to a tool inventory, you can use the Place

Tool Hits option on the Group Pattern submenu (Draw

menu) to position the custom pattern on your part.

You

can use the Define Special Tool and Define Cluster Tool Array options

on the Special Tool submenu to create special tools and then assign those

special tools to identical cluster patterns.

Options covered on this page are -

|

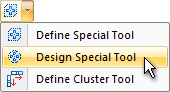

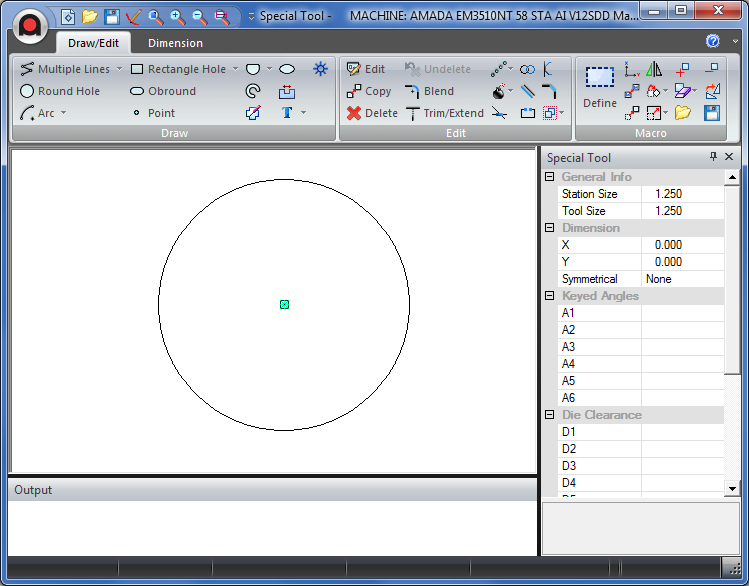

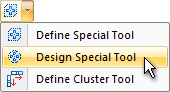

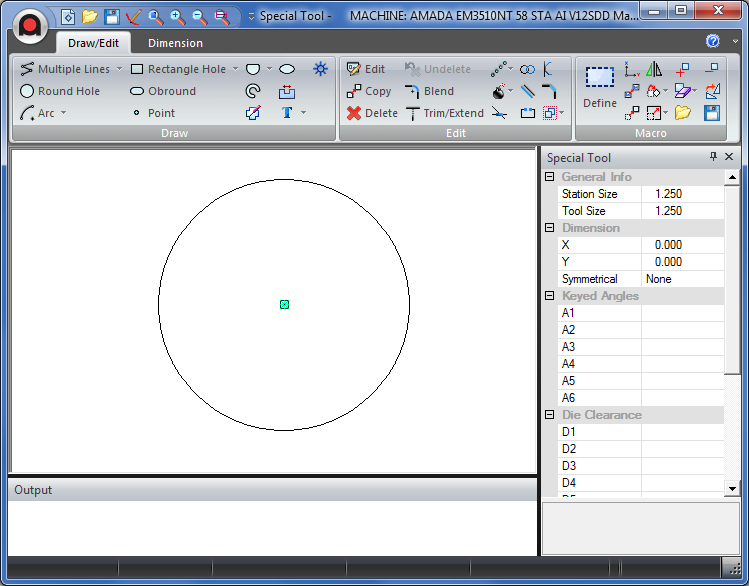

To draw a special tool, select

Design Special Tool from the Special Tool

submenu to open the Special Tool Designer window. The window displays

a circle having a reference point at its center, and the Special

Tool Information window. The circle represents the actual tool

size. If you modify the Tool Size value, the circle resizes accordingly

only after you place patterns within it. The Tool Size parameter

is saved with the special tool.

Note:

The system automatically begins a new special tool each time you

start the Special Tool application.

Note: When defining a Special

Tool and assigning tools, AP100US can snap not only to the default

point, but also to an additional point placed by the user.

Note: Changes saved to a

Special Tool in the Special Tool Designer module will automatically

be passed to the Tool Inventory.

The Draw/Edit/Macros

and Dimension

menus function as they do in AP100US.

|

|

|

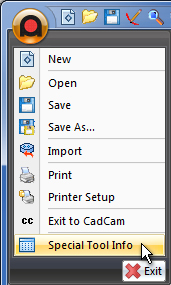

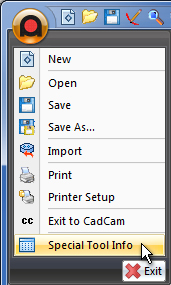

If

the Special Tool properties window is not open, click the Amada

"A" to open the main Special Tool menu.

Click

on Special Tool info as shown in the image.

|

|

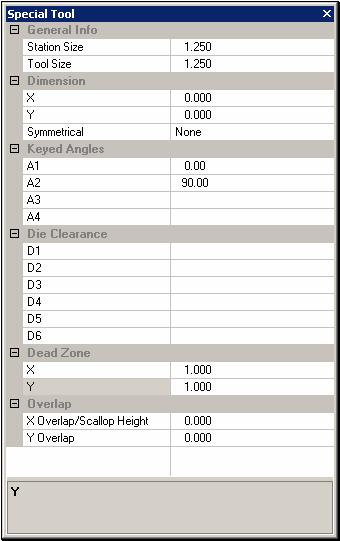

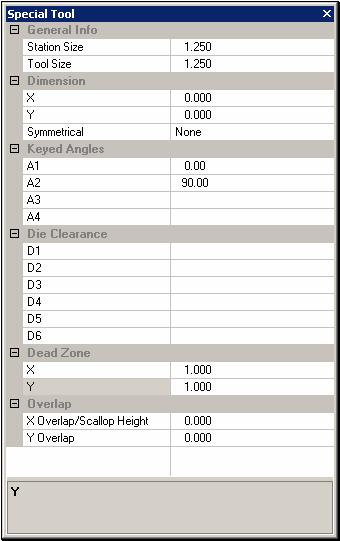

Use

the Special Tool properties window to define the tool. The window

disappears if you select another option. Open the window by selecting

Special Tool Info in the menu bar. You can

draw the tool after you have typed all the values.

When

defining a special tool, the system should use the overall X and

Y values of the Define box and transfer them to the X and Y values

in the Dimension fields. This will at least give the user the

overall size of the tool.

Notes

on snapping to points:

The point

or pattern in the Shape Definition can be used as the Center of

the Tool.

Actual

coordinates can be entered in the Coordinates

panel when placing a snap point on a special tool. It's also

possible to manually place a snap point by selecting Draw>Point

and then clicking on the part and editing coordinates in the Pattern

Properties panel that displays on the right side of the work area.

Note:

When a Special Tool is edited here in the Special Tools Designer,

changes made will automatically be updated to the Tool

Inventory. |

Option |

Description |

General Info |

|

Station Size |

Type the station size required

for the tool. |

Tool Size |

Type the size of the work

area required to draw the special tool. You want to specify the

Tool Size before drawing the tool. The value loads with the tool

and determines the size of the work area. |

Dimension |

You can record an X and Y

dimension (X is the smaller dimension; Y is the larger) for the

tool. |

X |

Type the X dimension for

the tool. |

Y |

Type the Y dimension for

the tool. |

Symmetrical |

There are three options you

can select from the drop-down list: None, Square and Rectangle.

You can specify whether the tool reacts to angles like a square

or rectangular tool. |

None |

No symmetrical setting. |

Square |

If you select Square, you

could assign the tool to patterns having the same direction, but

at different angles. For example, 0°, 90°, 180° and 270° would

be the same direction to a square tool. As long as the special

tool is in the turret at one of specified angles, it can also

be assigned to any other special tool that was at 90° intervals. |

Rectangle |

If you select Rectangle,

you could assign the tool to patterns having the same direction,

but at different angles. For example: 0° and 180° would be the

same direction, as would 90° or 270°. |

Keyed Angles |

You can input up to four

keyed angles for the tool.

After the keyed angles are

entered, the corresponding key angle marker will be displayed

in the workspace.

Note: It's best to define

at least on Key Angle, even if it is only 0.

|

A1 – A4 |

Die Clearance |

You can record up to four

die clearances. |

D1 – D4 |

Dead Zone |

Dead zones indicate the no-punch

safety area reserved around each tool within the system. The values

are half of the desired overall dead zone. Type the X and Y dimensions.

When the dead zone value

is specified on the special tool properties window on the right,

the system will show the dead zone in construction lines. |

Overlap |

You can record the overlaps

and scallop height. |

X Overlap/Scallop Height |

For non-round tools, the

X Overlap value allows you to specify the distance the tool should

overlap in the X or horizontal direction. For round tools, Scallop

Height allows you to define the height of the scallop formed during

a nibble process. The smaller the value, the less the scallop. |

Y Overlap |

For non-round tools, the

Y Overlap value allows you to specify the distance the tool should

overlap in the Y or vertical direction. |

|

|

|

Save a special

tool as you would any other part file. Save or Save As may be selected

from the File menu. Note: Changes saved to a Special Tool in the

Special Tool Designer module will automatically be passed to the Tool

Inventory.

You can easily

examine or modify a special tool you previously saved. Select Open

from the File menu. When the Open dialog box appears, type a file

name in the File name: text box, or navigate through the list and select

the name of the special tool. Click Open to load the special tool

into the work area.

You can also

import tool designs saved as DXF, IGES and DWG files. Click the Files

of type: arrow and select DXF (*.dxf), IGES (*.igs)

or DWG (*.dwg) from the drop-down list. The dialog box updates,

listing the files having the selected filename extension in the \Spectool

folder by default.

Type a file

name in the File name: text box, or navigate through the list and select

the name of the tool design file. Click Open to load the tool into

the work area. The software automatically converts the selected DXF, IGES

or DWG file to the Special Tool (*.spt) format when you load it.

Note: When

you load a DXF, IGES or DWG tool, the bottom left corner of the geometry

is placed at the center of the tool. You must relocate the tool to the

correct origin.

The Define

Special Tool option on the Tool menu allows you to select part

patterns and define them as special tools. To define a special tool requires

three overall steps: you must draw a marquee around the pattern(s), determine

the center point, and then edit the information in the Define Special

Tool window.

Notes: Use in Tool View.

The system uses the overall rectangular

zone of the selected patterns to calculate the tool size and to determine

the default center origin.

If you specify a center point

other than the default, the system multiplies the overall rectangular

zone by twice the distance specified for the center origin.

When patterns

are defined as a Special Tool, these patterns are automatically changed

to a group.

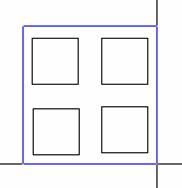

Example:

Define Special Tool

You have four center rectangles that

you want to define as a special tool. Select Define Special Tool

from the Special Tool submenu. Move into the work area. The system

prompts you to select the patterns you want to define as a special tool.

Move the crosshair to a point that is above and to the left of the four

rectangles. Click the left mouse button to start the marquee. Move the

crosshair down and right to enclose the patterns. When all the patterns

are enclosed within the box, click the left mouse button.

Selecting the patterns for

the special tool.

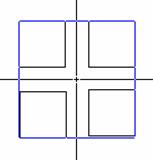

The

system now prompts you for the center point. Press <Enter> to accept

the default center point, or input the X and Y Offset coordinates and

press <Enter>. Click the right-mouse button to complete the operation.

The Define Special Tool window appears.

Selecting the center point

for the special tool.

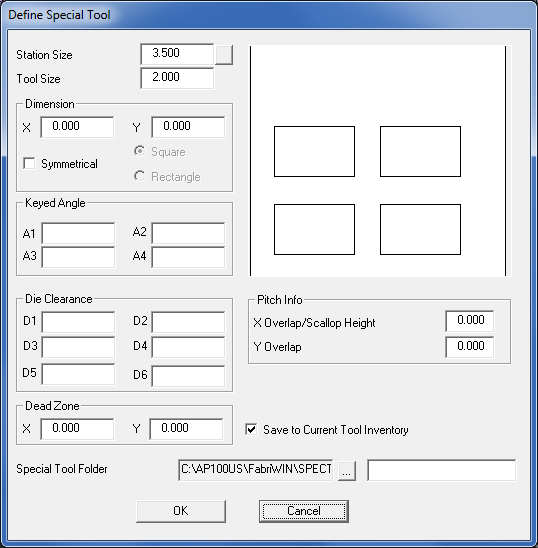

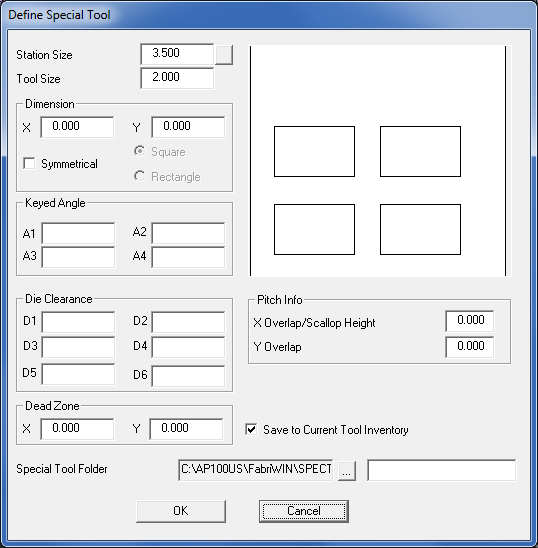

When you have

selected the patterns and specified the X/Y Offset for the special tool,

the Define Special Tool window appears. The preview pane to the right

displays a thumbnail image of the selected patterns.

Option |

Description |

Station Size |

Type the station size required

for the tool. |

Station Size Toggle Button |

|

The toggle button next to

the Station Size text box allows you to toggle through the available

keyed or auto-index station sizes of the currently loaded turret.

The software will analyze the overall size of the patterns and

automatically select the next largest station size, but you can

also type a new value in the Station Size text box to overwrite

the calculated value. |

Tool Size |

The software automatically

calculates the tool size according to the overall rectangular

zone of the selected patterns from the center origin or X and

Y offset. You cannot edit this value. |

Dimension (X and Y) |

You can record an X and Y

dimension (X is the smaller dimension; Y is the larger) for the

tool. |

Symmetrical |

If you enable Symmetrical,

you can specify whether the tool reacts to angles like a square

or rectangular tool. |

Square |

If you select Square, you

could assign the tool to patterns having the same direction, but

at different angles. For example, 0°, 90°, 180° and 270° would

be the same direction to a square tool. As long as the special

tool is in the turret at one of specified angles, it can also

be assigned to any other special tool that was at 90° intervals. |

Rectangle |

If you select Rectangle,

you could assign the tool to patterns having the same direction,

but at different angles. For example: 0° and 180° would be the

same direction, as would 90° or 270°. |

Keyed Angle (A1-A4) |

Use the text boxes, A1 to

A4, to record up to four angles at which the tool can be keyed. |

Die Clearance (D1-D4) |

Use the text boxes, D1 to

D4, to record up to four die clearances. |

Dead Zone (X and Y) |

Dead zones indicate the safety

area reserved around each tool within the system will not punch.

The values are half of the desired overall dead zone. Type the

dimensions in the X and Y text boxes. |

Save to Current Tool Inventory |

If there is a check mark

in the Save to Current Tool Inventory check box, the system

adds the special tool to the currently loaded Tool Inventory. |

Special Tool Folder |

|

The system saves the special

tool to the default \Spectool folder, but you can click the navigation

button to the right of the path information to choose an alternate

directory or new setup directory. |

|

To save the special tool

that you have defined, click in the File Name field and type a

name for the special tool. The system will automatically add the

*.spt filename extension. |

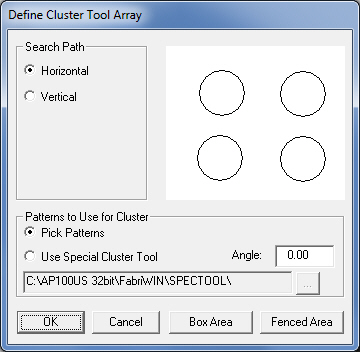

The Define

Cluster Tool Array… option on the Special Tool submenu allows

you to determine the center points of cluster tools (more than two tools

in a group) to generate perforated sheets or part areas. This option allows

you to select a pattern set, define a special tool from that set, and

then search the part or sheet for identical cluster patterns. The system

then assigns the tool as a single hit and continues to search for matching

patterns.

You can use

two methods to define a cluster tool array. You can select a pattern array,

define it as a special tool, and then have the system apply it to the

patterns. The other method involves the system searching for array patterns

and assigning an existing special tool.

Notes: As a rule, the system

attempts to apply the special tool to the array according to the Horizontal

or Vertical options in the Define Cluster Tool Array window. The software

essentially ignores any irregular shapes, thereby reducing the amount

of processing time.

When prompted to select the cluster

array area, the patterns in the array must match those of the special

tool.

The system displays the “No cluster

patterns match selected area” message if it cannot find any matching patterns

during the first search path.

If there are common distances

between the centers of the special shape, the system will group the pattern

as a pattern line, otherwise, a single hit placement is assigned to the

grouped special tool.

The system displays a message when

it completes the processing of the cluster area.

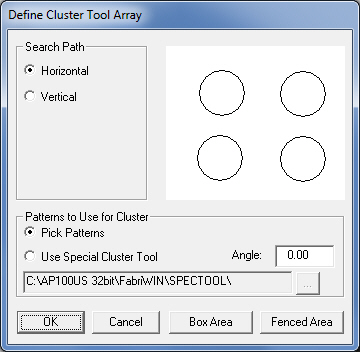

The options in the Define

Cluster Tool Array window allow you to select cluster array patterns

to define as special tools, and then assign the selected patterns

as tools, or assign a previously defined special tool to a pattern

array. |

|

Option |

Description |

Search Path |

Use the options in this section

to specify the search path. |

Horizontal |

Select Horizontal if you

want the system to search for matching cluster patterns horizontally

row-by-row. |

Vertical |

Select Vertical if you want

the system to search for matching cluster patterns vertically

column-by-column. |

Preview Pane |

The Preview Pane to the right

of the Search Path options displays a thumbnail image of the selected

cluster array or of the currently selected special tool. |

Patterns to Use for Cluster |

Use the options in this section

to choose the selection method. |

Pick Patterns |

Select this option if you

want to draw a rectangular marquee around the patterns. The Box

Area and Fenced Area options become available. |

Use Special Cluster Tool |

Select this option if you

want to use the previously defined cluster tool or to choose an

alternate cluster tool for the array. |

Angle |

Special Cluster Tool can

now process pattern array with this given angle

|

Path Information |

This field displays the current

path and filename for the cluster tool. You can click the navigation

button to the right and select an alternate cluster tool to apply

to the array patterns. |

OK |

Click OK to begin the selection

process. |

Cancel |

Click Cancel to exit the

Define Cluster Tool Array window. |

Box Area |

Click Box Area to draw a

rectangular marquee around the patterns you want to define as

a special cluster tool. |

Fenced Area |

Click Fenced Area to draw

a freehand rectangular marquee around the patterns you want to

define as a special cluster tool. Make sure to snap the end point

of the last line to the start point of the first line to complete

the fence. |