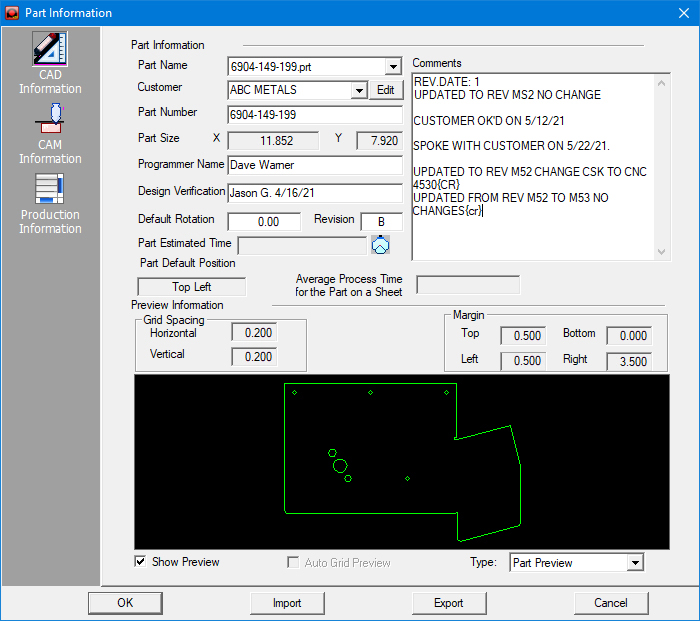

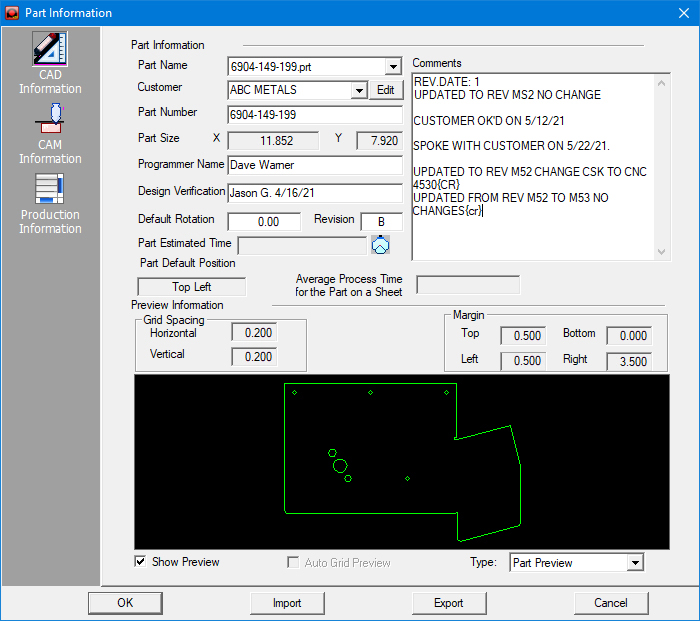

The options in the CAD

Information panel allow you to specify a part number, programmer

name, the default rotation and revision, and Part Default Position.

You can also add comments for the part. |

|

Notes: |

1. Margin,

Grid Spacing and Default Position values are transferred from

the Auto Grid Information section (Machine\Machine Info\Description)

setting |

2. The

system will select the corresponding margin value according to

the part Default Position. For example, if you choose Bottom Left

as the default part position, the system will apply the Left and

Bottom margin values for the part. |

3. The

Default Rotation angle range is from -180o to 180o.

If you type a position value, the part will rotate clockwise.

If the value is negative, the part will rotate counter-clockwise. |

4. The

part rotation will only appear if Sheet Preview (Type)

mode is active. The Default Rotation value can be saved after

you modify it. |

5. The

system will output the Part Number, Programmer Name and Comments

in the NC code file. |

|

Part

Name |

Optional. Type the part name

in the text box, or click the arrow and select a part name from

the drop-down list. When adding a new part name, the system automatically

stores it in the nesting database for future reference.

Also, the

Part Name pull-down list allows the user to switch between parts

on the sheet

that are in the pull-down list. |

|

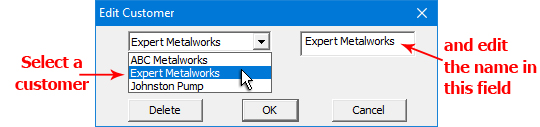

Customer |

Entering

a name directly in this field and clicking OK in the Part Info

panel will create a new database record for a new customer.

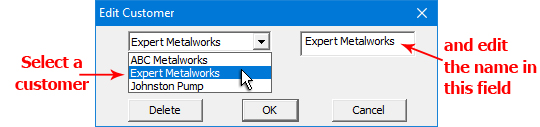

To

modify the name of an existing customer (database record) click

the Edit button to open the dialog. Select the Customer's name

from the pull-down and edit the name in the field.

To delete a selected customer

click Delete

|

|

Part

Number |

Required field. Type the

part number in the text box. |

|

Part

Size |

Default field. The overall

dimensions for the part appear in the X and Y text

boxes. |

|

Programmer

Name |

Optional. Type the name of

the person responsible for programming the part. |

|

Design

Verification |

Here the user may enter the

name and/or number of the person who has verified the design of

this part. |

|

Default

Rotation |

The default angle of the

part when it is loaded into the system. You can type a new angle

value in the text box. |

|

Revision |

Optional field. If a part

has been revised (edited) type the revision number or letter in

this text box. A value entered here will be available in the Sheet Wizard>Parts List for Nesting,

Revision column and in the Open

File window. |

|

Part Estimated

Time |

Once

the run time for a part is calculated, the time will display in

the Part Estimated Time text-box. To update the estimate, click

the Run Time button  . .

Note: The Run Time button

is enabled only when a Driver, Tool Inventory, Machine and Part

with assigned tools or cutting path exist.

See View Run Time

for more information. Note:

The NC code must be re-generated when any changes have been made

to the part/sheet. |

|

Part

Default Position |

The default position is the

bottom left of the sheet. You can open the drop-down list and

select an alternate position: Top Left, Bottom Left, Top Right

or Bottom Right. |

|

Average

Process Time

for the Part on a Sheet |

This read-only text box displays

the Average Process Time for the Part when it is being cut/punched

on a Sheet along with other parts. The system will average out

the Part time based on various factors, such as the number of

tool hits, tool change time and repositioning. |

|

Comments |

Enter any relevant notes

that should be saved with the part in this box. |

|

Grid Spacing |

The Horizontal and Vertical

spacing for the parts in the grid.

Specify the Horizontal

and Vertical spacing for the parts in the grid. |

|

Margin |

The intervals between the

part and sheet sides. Specify the parameters for the Left,

Right, Top and Down edges for the auto grid. |

|

Show Preview |

This option is a toggle.

If you place a check mark in the check box, the Preview area will

display the part or the part in relation to the sheet. |

|

Auto Grid Preview |

This option is a toggle.

If you place a check mark in the check box, the auto grid result

will appear on the sheet. |

|

|

|

|

Type |

Select the desired Preview

type from the drop-down list: Part Preview or Sheet Preview. |

|

OK /

Cancel |

Click OK to apply the settings

to the current part and to exit the Part Information window.

Click Cancel to exit without saving any changes. |

|

Import |

Clicking the Import button

displays the Open>Parts dialog box.

In addition to standard inv

files, the user may choose to load from Tool Inventory files in

.XLS or .CSV formats. From here it is also possible to create

and edit .xls and .csv files. See Export

below for more info on this. |

|

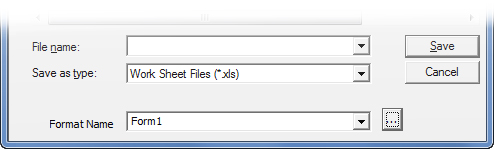

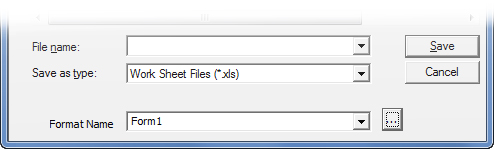

Export |

To export Tool files in .XLS

or .CSV formats, click Export.

The Save As dialog will open allowing the user to save directly

to the TOOLINV folder in the AP100US installed folder in either

.xls or .csv format.

The Save As folder contains

a Format Name and button. The user may select from existing formats,

or click the button to open the Format Options window to create

or edit formats.

See Exporting Files

in XLS or CSV formats in the Material Files folder for more

info on creating and editing .xls and .csv files. |