Amada ULX Unloader

What is the Amada ULX Unloader?

|

The Amada ULX Unloader module is an optional

software package that enhances the functionality of the CAD/CAM

System. The procedure outlined in this manual only addresses the

general features of ULX Unloader. Specific procedures vary from

one machine to the next. Please contact your Amada representative

for information specific to your machines. The ULX Unloader option

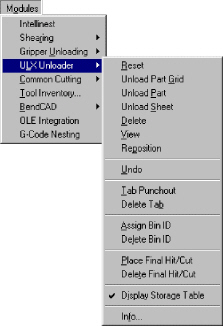

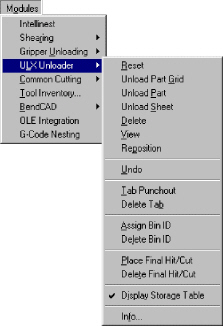

is located on the Modules menu. To access the options on the ULX

Unloader submenu, you must first open the Modules menu, and then

select the option (using the mouse or keyboard) to list the commands.

To ensure the options on the ULX Unloader submenu are active when

you begin your session, the following conditions must be in effect:

1. Your machine driver must support ULX

unloading functions.

Sheet

view must be active. You cannot use the gripper unloading

options if Part view is active. If the Info

option is active, but the remaining

options are disabled, you must use the Info

option first to specify the ULX

information. |

Quick Start Guide

The

Quick Start Guide summarizes the gripper unloading process. Review this

outline of the Gripper Unloading features. For commands or tasks you do

not fully understand, reference the appropriate section.

Start ULX Unloader

To prepare for ULX Unloader, launch the CAD/CAM

System. Select Sheet from the View

menu. Sheet view must be active before you

can use any of the options on the ULX Unloader submenu.

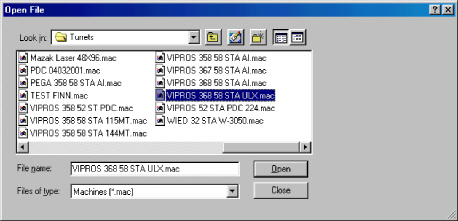

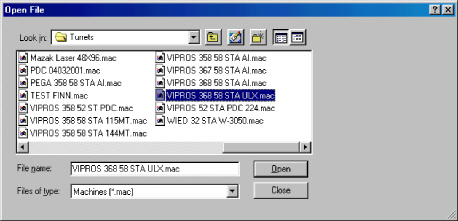

Load the Machine File

Select Open

from the File

menu, or click the Open File button in the

Standard toolbar. When the Open File dialog box appears, select

Machines (*.mac) from

the Files of type:

drop-down list. The system lists the machine files stored in the \Turrets

directory by default. If necessary, use the Look

in: drop-down list to navigate the

hierarchical folder structure. Scroll through the file list window and

click the name of the machine file. Click Open

to load the machine file. If necessary, edit

or load a material file. Click Close

to exit the Open File dialog box.

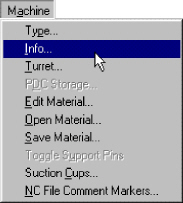

Load the Machine Driver

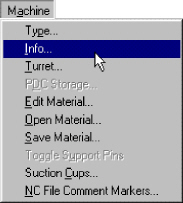

Select Info

from the Machine

menu to open

the Machine Setup window. Click the Driver File button.

The Open dialog box displays the machine drivers stored in the \Machine

directory by default. If necessary, use the Look

in: drop-

down

list to navigate the hierarchical folder structure. Scroll through the

file list window and click the name of the driver file. If necessary,

edit or load a material file. Close the Machine Setup window.

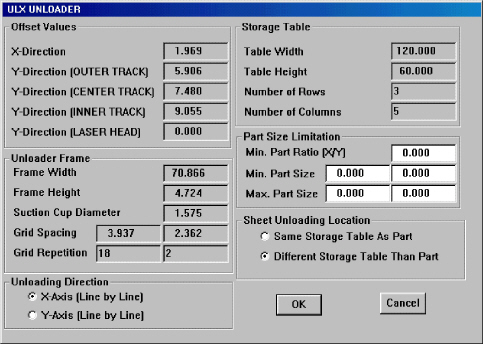

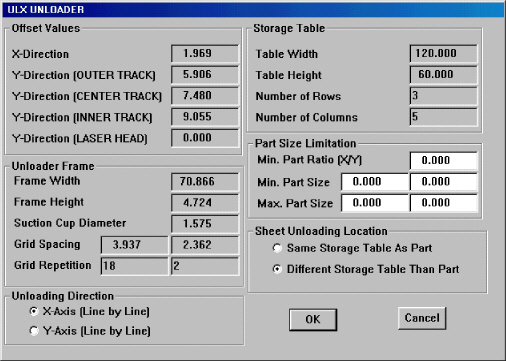

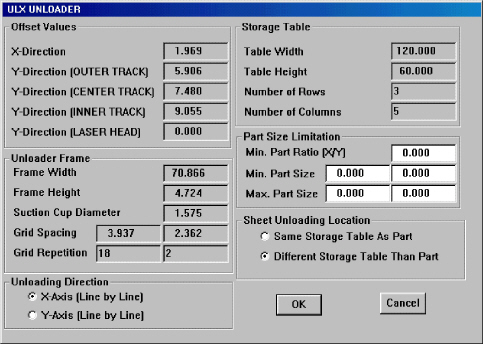

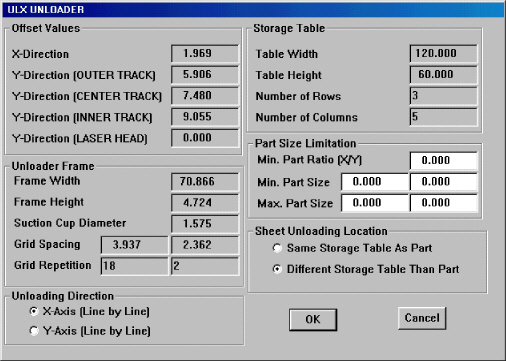

Specify the ULX Unloader Information

Open the Modules

menu. Select Info

from the ULX

Unloader submenu to open the ULX Unloader

window. Specify the Unloading Direction, Part Size Limitations, and Sheet

Unloading Location by either typing the values in the text boxes or by

selecting the appropriate option buttons. Click OK to save the ULX Unloader

information.

Create the ULX Unloader Sheet

Load

the parts on the sheet and grid them if necessary. Assign the tools to

the patterns. Place the final hits or cuts and assign the Bin IDs.

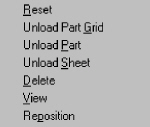

Sequence the ULX Functions

|

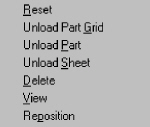

Use the

Reset,

Unload Part Grid,

Unload Part,

Unload Sheet,

Delete,

View and

Reposition options

on the ULX Unloader

submenu to remove the parts from the sheet.

You can also use the respective buttons on the toolbar to define

the

ULX unloading sequence.

|

Save the ULX Sheet

Select Save

As from the File

menu, or click the Save As button in the Standard

toolbar to open the Save As dialog box. Select Sheets

(*.sht) from the Save

as type: drop-down list. Type an appropriate

name in the File name: text box. Click the Save

button to save the ULX sheet. Click the

Close button

to exit the dialog box.

Overview

The

basic procedure for using the Amada ULX Unloader includes:

Review or specify the Amada ULX Unloader

information, especially the sheet values for part limitations.

Create a part or parts and assign tools.

Define the sheet(s) and arrange the parts

on the sheet(s).

Place final hits or cuts. Technical support

representatives recommend using last

hits,

rather than

last cuts,

to minimize machine movement when freeing a part from the sheet.

Assign Bin IDs.

Sequencing the sheet.

Tab Punchout (optional).

Unload part grid or parts.

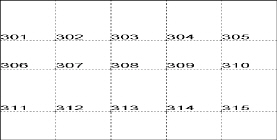

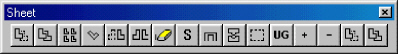

Amada ULX Sheet

When working

with an Amada ULX sheet, use

the Zoom In option on the View menu to enlarge

the details. Use Zoom All on the View menu to

see both the sheet and the storage

area. |

Amada ULX Storage

Area and Bin ID Numbers

|

Note: If you do not want to display the storage

area, remove the check mark from the Display

Storage Area option on the ULX Unloader

submenu. |

|

Preparation

Load the Machine File

A machine file contains the physical parameters

of a machine. You must load the correct machine file before you can define

a sheet having gripper functions. Machine files have the filename extension

of *.mac,

and are stored in the \Turrets directory by default.

To load the machine file:

Select Open

from the File

menu, or click the Open File button in

the Standard toolbar. The Open File dialog box appears.

Click the Files

of type: arrow and select

Machines (*.mac) from

the drop-down list.

If necessary, use the Look

in: list to navigate the hierarchical

folder structure.

Scroll

through the file list window and click the name of the machine file

you want to load.

- Click Open to

load the machine file, and then click Close

to exit the dialog box.

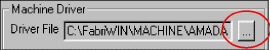

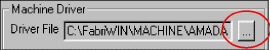

Load the Machine Driver

|

The next step involves checking the machine

driver, and if necessary, selecting the correct driver that supports

gripper-unloading functions. Your machine driver must support

gripper functions before you can use them. Please contact your

CAD/CAM System representative for more information on custom drivers.

Select Info

from the Machine

menu to open the Machine Setup

window. The Setup Values page

displays by default. Click

the Driver File  button in the Machine

Driver button in the Machine

Driver

section.

When the Open dialog box appears, the name of the current

driver displays in the File

name:

text box.

If the driver is correct, then click

the Close button to exit the Open dialog box.

To load an alternate driver, navigate through the file list

and click the name of the driver you want to load. Click the Open

button to load the driver. You

may be prompted to create or load a material file.

See the Material Files section

in Chapter 7: Machine Files of the CAD/CAM System manual for

more information. Click Save

in the Machine Setup window. |

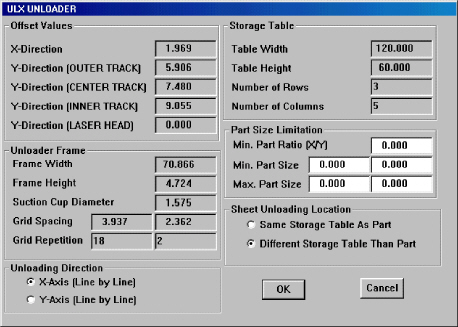

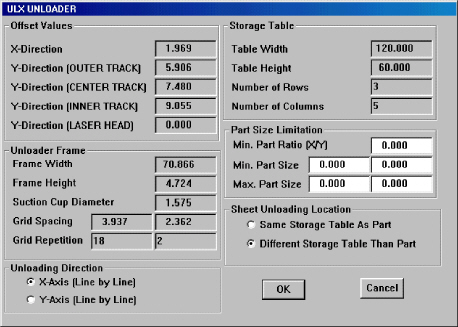

ULX Unloader Window

You

must specify the ULX Unloader information before you can use any of the

functions. If this information already exists in the machine driver, then

you only need to examine the values to ensure they are correct. If necessary,

you can view and edit the values for the part size limitations on the

sheet.

To

display the ULX Unloader window:

Make sure Sheet view is active. If necessary,

select Sheet from

the View menu.

Open the Modules

menu, and highlight (select) ULX Unloader to

open its submenu.

Select Info

from the ULX

Unloader submenu, or click the

Info button in the ULX toolbar. When the ULX Unloader window opens,

the contents of the X-Direction

text box in the Offset Values section

are selected by default.

Type

the values in the various text boxes. You can navigate the text box

fields within the window using a combination of the <Tab> and

<Shift> keys. Press <Tab> to move to the next field, or

<Shift> + <Tab> to select the contents of the previous

field.

When the information appears correct, click

the OK button

to save the changes and to exit the ULX Unloader window.

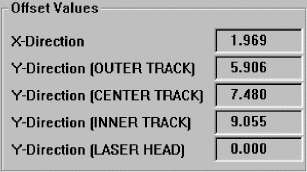

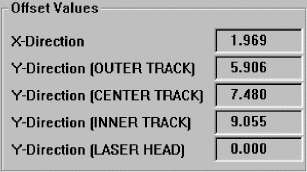

Offset Values

The

fields in the Offset Values section display information for the offset

from the punch head at the three track locations (or the laser head) as

measured in the X and Y directions to the center of the first pair of

suction cups.

Offset Values Information

X-Direction The offset from the

turret station in the X direction.

Y-Direction

(Outer Track) The offset from outer track stations in the Y direction.

(Outer

track stations are 300 through 399.)

Y-Direction

(Center Track) The offset from the center track stations in the Y direction.

(Center

track stations are 200 through 299.)

Y-Direction

(Inner Track) The offset from the inner track stations in the Y direction.

(Inner

track stations are 100 through 199.)

Y-Direction

(Laser Head) For combination machines, the offset for the laser head in

the Y direction

(usually a negative value).

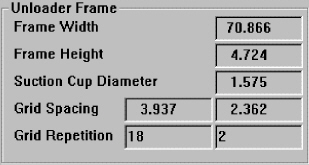

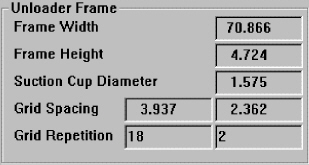

Unloader Frame

The

fields in the Unloader Frame section display information for the size

of the unloader frame that removes the parts.

Unloader Frame Information

Frame

Width The X measurement or width of the gripper frame.

Frame Height The Y measurement

or height of the gripper frame.

Suction

Cup Diameter The diameter of the suction cups.

Grid

Spacing The two fields following the label display the spacing of the

suction

cups in the X and Y directions respectively.

Grid

Repetition The two fields following the label display the number of suction

cups in

the X direction and Y direction respectively.

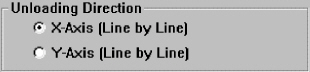

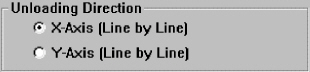

Unloading Direction

The

X-Axis (Line by Line) and Y-Axis (Line by Line) options in the Unloading

Direction section determine the direction the Amada ULX Unloader should

move when unloading grids of parts.

Unloading Direction Information

X-Axis

(Line by Line) This option instructs the system to move the unloader in

the X- axis before moving in the Y-Axis.

Y-Axis

(Line by Line) This option instructs the system to move the unloader in

the Y- axis

before moving in the X-Axis.

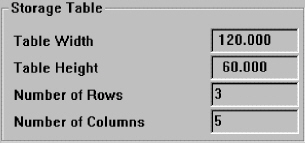

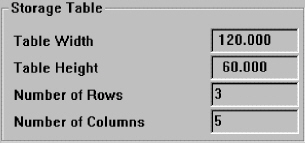

Storage Table

The

Storage Table section displays the parameters of the storage table that

holds the parts after unloading.

Storage

Table Information

Table Width The width or X dimension of the table.

Table

Height The height or Y dimension of the table.

Number

of Rows The number of rows available for storage on the table.

Number

of Columns The number of columns available for storage on the table.

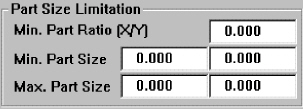

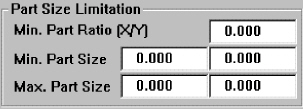

Part Size Limitation

The

Part Size Limitation information is critical.

Part Size Limitation Information

Min.

Part Ratio (X/Y) Type a ratio between the X dimension and Y dimension

of the part that the gripper can handle during

unloading. Divide the part's X by the Y, and then type the fraction that

results. A part having a ratio larger than this number can be unloaded.

This ratio ensures the weight of the part is supported when suction cups

cover the part's surface.

Min.

Part Size The minimum X and Y dimensions of the part the unloader can

handle.

Max.

Part Size The maximum X and Y dimensions of the part the unloader can

handle.

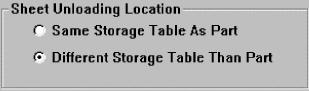

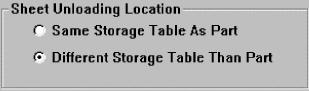

Sheet Unloading Location

This

section allows you to specify where the sheet should be unloaded.

Sheet Unloading Location Information

Same Storage Table As Part If

you select this option, the unloader stores the sheet

with the part.

Different

Storage Table Than Part If you select this option, the unloader stores

the sheet

in a different storage table than the part.

Save the Machine File

To save

the changes you made to the machine file:

To save

the changes you made to the machine file:

Select Save

As from the File

menu, or click the Save As button in the

Standard toolbar. The Save As dialog box appears.

Select Machines

(*.mac) from the Save

as type: drop-down list.

Type an appropriate name in the File name: text

box.

Click the Save

button to save the machine file.

Click the Close

button to exit the dialog box.

Creating a Sheet with ULX Functions

Once

you have loaded the correct machine file and ULX driver, and specified

the correct values in the ULX Unloader window, you can add the actual

ULX functions to the sheet. This involves placing the final hits/cuts

and assigning the Bin IDs.

Note: Make

sure to check the gripper information before you begin. Use the

Info option

on the ULX Unloader submenu

to open the Unloading Gripper window.

Parts and Tool Assignments

To

begin the process, create the parts you want to arrange on the sheet and

assign tools to the patterns.

Notes:

See Chapter

8: Tool Assignment, in the CAD/CAM

System manual, for more information regarding tool assignments for

punching systems.

See Chapter

11: Cut Sequence, in the CAD/CAM

System manual, for information regarding tool assignments for cutting

and combination systems.

Layout the Sheet

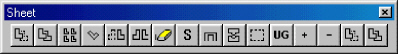

Use the options on the Sheet menu or Sheet toolbar

to create the part layout. See Chapter

5: Sheet Layout, in the CAD/CAM System

manual, for more information.

Final Hits and

Cuts

Final

Hits are the last hits (or cuts) on the part. The system uses these hits

to break the part free from the sheet. You have two options: Place Final

Hit/Cut and Delete Final Hit/Cut. If you choose punched patterns, you

are defining the last hit. If you have a combination machine and select

cut patterns, you are defining the last cut.

Notes:

Before

placing final hits, you must assign tools to the last hit pattern

on each part.

When

choosing the last cut for a combination system, you cannot choose

a path having a start point or bridge microjoint. Technical support

recommends that you use last hits instead of last cuts.

A

sequenced single hit cannot be the final hit until you first reset

or remove the sequence.

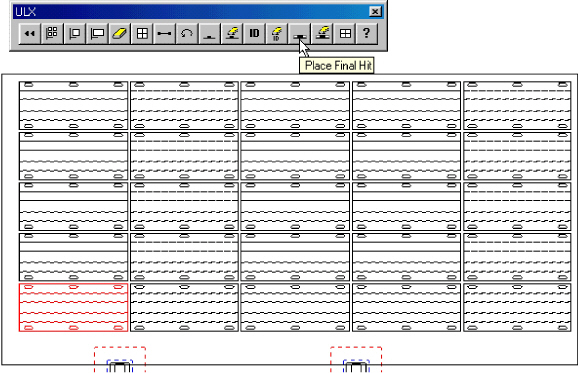

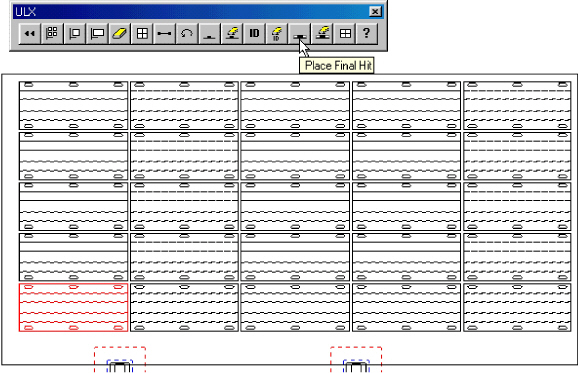

Place Final Hit/Cut

To

place a final hit or cut:

To

place a final hit or cut:

Select Place

Final Hit/Cut from the ULX Unloader submenu,

or click the Place Final Hit button in the ULX toolbar.

Move

into the work area and click a pattern (a line, arc or tool hit placed

using Place Tool Hit) to assign the final tool hit or cut.

Slide

the mouse along the pattern to position the suction frame (the suction

frame is represented as a rectangle) and suction cups over the part.

Click

the left mouse button to select the position, and then use the left

mouse button to toggle the individual cups either on or off (active

cups appear in a solid color; inactive cups appear as concentric outlines).

When

you have activated the suction cups you want to use, click the right

mouse button.

Delete Final Hit/Cut

|

To remove a final

hit or cut: |

|

Select Delete

Final Hit/Cut from the

ULX Unloader submenu,

or click the Delete Final Hit button in the ULX toolbar. |

Bin IDs |

Move

into the work area and click each part from which you want

to remove the final hit. |

The

system uses Bin IDs as cross-references, assigning each part a particular

area on the storage table after it is broken out of the sheet. Your options

include assigning and deleting bin identification numbers.

Note: If

you do not assign bin identification numbers, the system prompts you for

the Bin IDs when you unload the parts or part grids. For part grids, you

can use this technique to unload the parts in different bins.

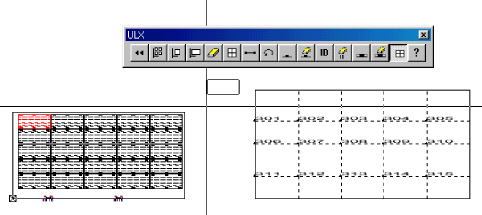

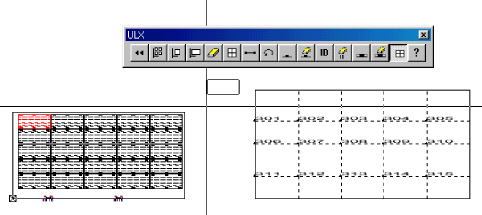

Assign Bin ID

To

assign bin identification numbers:

To

assign bin identification numbers:

If necessary, display the storage table and

bin numbers. Make sure that Display

Storage Table on the ULX Unloader submenu

has a check mark, or click the Display Storage Table button in the

ULX toolbar.

Select Assign

Bin ID from the ULX

Unloader submenu, or click the

Assign Bin ID button in the ULX toolbar.

Move

the crosshair over a part or part grid that requires a bin identification

number and click the left mouse button. An outline of the part begins

to follow the crosshair.

Drag

the part into the storage area over the desired bin and click the

left mouse button. The part outline appears on the Bin ID.

The

Bin ID number assigned to each part displays within its part boundaries.

You can view these Bin ID numbers any time you select Delete Bin ID or

Assign Bin ID.

Delete Bin ID

To

remove bin identification numbers:

Make

sure Sheet view is active.

Select

Delete Bin ID from the ULX Unloader submenu, or click the Delete Bin

ID button in the ULX toolbar.

Move

into the work area. The Bin IDs appear on each part or part grid having

a bin identification assignment.

Click

each part or part grid from which you want to delete the Bin ID.

Sequencing the ULX Sheet

Once

you have placed the final hits/cuts and assigned bin IDs to the parts,

you are ready to sequence the ULX sheet. The Reset, Unload Part Grid,

Unload Part, Unload Sheet, Delete, View, Reposition, Undo, Tab Punchout

and Delete Tab options allow you to control the sequencing process.

Unload Part Grid

The

Unload Part Grid command allows you to unload an entire grid of parts.

If you have not yet punched bridge microjoints, this command sequences

them and the last hit before unloading all the parts in the selected grid.

If you want to control the sequencing order for the microjoint tabs, use

the Tab Punchout command.

Note: You

must assign the last hit before you can use this option.

To

unload a part grid:

Select Unload

Part Grid from the ULX Unloader submenu,

or click the Unload Part Grid button in the ULX toolbar.

Move

into the work area and click a part on the sheet belonging to the

grid.

If

the parts have Bin IDs, the system displays a series of driver-related

questions

in the message window and unloads the parts.

If the parts were not assigned Bin IDs, the system requests a bin

identification number for each part in the grid. Type the Bin ID number

and press <Enter>.

Unload Part

This command allows you to unload individual

parts. The bridge microjoints and last hit are sequenced before the system

unloads the part (See Unload Part

Grid). Use the Tab Punchout command

if you want to control the sequencing order for the microjoint tabs.

Note:

You must assign the last hit before you can use this option.

To

unload a part:

Select Unload

Part from the ULX

Unloader submenu, or click the

Unload Part button in the ULX toolbar.

Move

into the work area and click the part you want to unload.

If

the part has a Bin ID, the system displays a series of driver-related

questions in the message window and unloads the part. If the part

does not have a Bin ID, the system requests a bin identification number

for the part. Type the Bin ID number and press <Enter>.

Tab Punchout

|

Use this option

before unloading parts if you want more control over the sequencing

order for bridge microjoints. You must place bridge microjoints

on the part in Part view before you can use this option. Use Tab

Punchout after completing your sequencing and just before unloading

the part or part grid.

Note:

If you choose not to use Tab Punchout to sequence microjoints,

the Unload Part and Unload Part Grid options sequence the microjoints

using the same order as when they were originally added to the

part. The microjoints are sequenced just before the last hit is

punched.

To use the Tab Punchout option:

Select Tab

Punchout from the

ULX Unloader submenu,

or click the Tab Punchout button in the ULX toolbar. Move

the crosshair into the work area. Click

the part with microjoints that you want to sequence. The

pointer bounces between the bridge microjoints on the selected

part. Click each microjoint you want to punch using the left

mouse button in the order you want them punched. (The first

microjoint you click is punched first; the second is punched

second, and so on.) When

you finish sequencing the punch outs for tabs on the first

part, click the right mouse button so that you can continue

onto the next part. Click

the next part with microjoints that you want to sequence. Repeat

these steps for each part on the sheet for which you want

to control the sequencing of bridge microjoints. |

Delete

Tab |

|

The Delete Tab option removes the tab sequencing

you defined using the Tab Punchout command. To remove the tab

sequencing:

Select

Delete Tab from the ULX Unloader submenu, or click the Delete

Tab button in the ULX toolbar. Move

the crosshair into the work area. Click

the part with microjoints that you want to unsequence. The

pointer bounces between the sequenced bridge microjoints on

the selected part. Click each microjoint you want to unsequence

using the left mouse button. Click

the right mouse button when you want to unsequence microjoints

on a different part. Click

the next part with microjoints that you want to unsequence

and repeat these steps. |

Undo

|

Use the

Undo command

on the ULX Unloader

submenu, or click the Undo button

on the UXL toolbar, to reverse the last ULX sequencing command

you selected. |

Delete |

|

To erase an

unloading sequence for a part or part grid, select Delete from

the ULX Unloader

submenu, or click the Delete button

in the ULX toolbar. Move into the work area and click the part

or grid of parts. The sequence is removed from the part or part

grid. |

View |

|

To see the ULX

unloading sequence, select View

from the ULX

Unloader submenu, or click

the View Sequence button on the ULX toolbar.

Note:

Use the Viewing Speed command on the Options menu to control the

redraw rate of the sequence. |

Reposition |

|

Repositioning

allows you to move the work area to punch or unload parts that

are out of range. The repositioning function opens the clamps

and moves them so you can complete the remainder of the sheet.

You can also reposition in the reverse direction to return the

clamps so the sheet does not hang off the edge of the table.

To reposition the clamps during a ULX unloading sequence, select

Reposition from

the ULX Unloader

submenu, or click the Reposition button

on the ULX toolbar. The prompt instructs you to move into the

work area and set the reposition location. As you move the pointer

across the sheet, the reposition line appears and prompt asks

you to choose its location. The location of the reposition line

relative to the lower left corner of the sheet indicates the direction

and distance you want the clamps to move.

As you move closer to the left edge of the sheet, you will see

a rectangle following the pointer. This represents the machine

bed. The patterns that appear inside this rectangle are within

range. When the patterns you want to sequence with gripper functions

appear inside the rectangle, click the left mouse button. The

repositioning line locks onto the sheet, and two solid blocks

that represent the repositioning posts appear. The repositioning

posts follow the pointer around the work area and a prompt instructs

you to choose their placement. Make sure the posts do not fall

inside a cutout on the part. When you are satisfied with the location,

click the left mouse button. Use the other options to complete

the gripper sequencing after repositioning.

|

Reset |

|

The Reset option on the ULX Unloader submenu

allows you to clear any previous ULX unloading sequences. To clear

the unloading sequence, select Reset form the ULX Unloader submenu,

or click the Reset button in the ULX toolbar. The system prompts

you to confirm the action. Press <Y> for “Yes” to reset

the sequence, or <N> for “No” to cancel. |

Unload Sheet

|

When the sequencing

is complete, use the Unload Sheet command on the ULX Unloader

submenu, or click the Unload Sheet button on the ULX toolbar,

to unload the sheet. Note: You may want to review the Sheet Unloading

Location options in the ULX Unloader window to determine whether

the sheet unloads to the same storage area or to a different storage

area. See ULX Unloader Window

and Sheet Unloading Location. |

Display

Storage Table |

|

Display Storage Table is a toggle. It either

displays or hides the storage table when Sheet view is active.

If you enable the option, the storage table displays if you have

a ULX machine file loaded. To hide the display of the storage

table, remove the check mark. |

Saving the ULX Sheet

You

should save your sheet frequently to prevent data loss during power outages

or computer crashes. If you press the <F10> key while in Sheet view,

the system saves your sheet under its assigned name in its default folder.

Note: If

you have not yet named the sheet, pressing <F10> saves the sheet

with the default name of NEW SHEET.

To

save the sheet:

Make

sure you are in Sheet view. To save the sheet under a new name, select

Save As from the File menu, or click the Save As button in the Standard

toolbar. The Save As dialog box appears.

If necessary, select Sheets

(*.sht) from the Save

as type: list. Type a name in the

File name: text box. You need not add the filename extension; the

system automatically adds the *.sht

extension.

Click the Save

button to save the sheet. Click the

Close button

to exit the Save As dialog box.