In previous versions of the CAD/CAM System, the software maintained the sequencing if the machine types were the same. However, due to changes in the machine driver and material file formats, the processing functionality now varies depending on the situation. If necessary, the system will prompt you for further action. The following scenarios address the issues surrounding attributed parts and sheets that you load into the system.

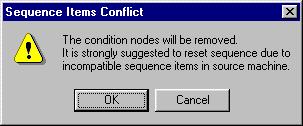

Sequence Items Conflict

In this scenario, a cutting sheet has special sequence items that are incompatible with an alternate machine file and machine driver that you are loading. The software maintains the sequence order start points, features and microjoints, but detects the conflicting sequence items. The Sequence Items Conflict dialog box appears after you load the machine but before you select the material file:

If you click OK, the software removes the special sequence items and conditions, but does not reset or reprocess the sheet or parts. It is recommended that you do reset the sequence. If you click Cancel, the system returns to the previous machine settings.

Note: If there are no material files associated with the machine, the software will use the material defaults of the current machine to process the sheet and/or sequence the part.

Processing in Part View

If you retrieve a part from the Part View window, and that part has the Keep Attributes flag, the Process button is disabled. However, when you open new parts, or *.dxf, *.dwg, and *.igs files, the Keep Attributes function is disabled and the Process button becomes available.

Note: When using a punching machine, the Keep Attributes function is disabled. The attribute only applies to cutting and combination machines.

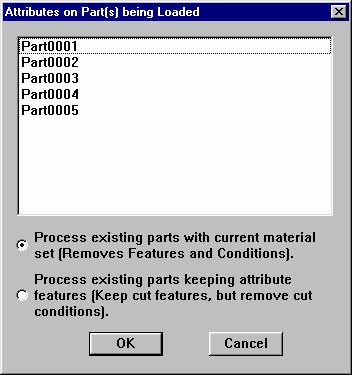

Processing in Sheet View or Importing

In this scenario, when you import parts having a different machine driver and material settings, you must decide whether you want to process the parts with the current material parameters, or process the parts while maintaining the attribute features.

If you select Process existing parts with current material set, the software will clear all the attributes on the part(s) and process for the current material settings contained within the current driver. If you select Process existing parts keeping attribute features, the system maintains the cutting features, such as microjoints, corner features, etc., but removes any cutting conditions (including any conditions assigned to the corners).

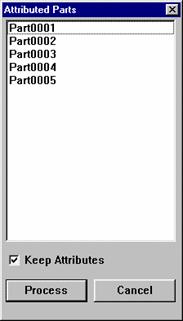

Processing in Sheet View using the Same Driver

When the Keep Attributes flag is enabled, and the same driver is used on all the parts, but some of the parts were saved with Keep Attributes enabled while others were not, the system does not adjust any attributes or conditions of the attributed parts. It does, however, proceed to process the remainder of the parts. If the Keep Attributes flag is disabled for any particular parts, and you click the Process button in the Part View window, the Attributed Parts window appears.

The Attributed Parts window essentially allows you to escape from the Process function, thereby preventing it from affecting the pre-attributed parts. If you want to maintain the attributes for the part(s), make sure a check mark appears in the Keep Attributes check box and click Process. If, however, you want to apply the current material settings to the part(s), remove the check mark from the Keep Attributes check box and click Process.