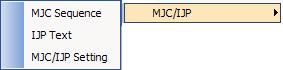

The option MJC/IJP

is found in the Modules menu. There are three options:

MJC Sequence, IJP Text and MJC/IJP Setting. |

|

Option |

Description |

MJC Sequence |

Defines the sequence the machine will use

to cut the microjoints. |

IJP Text |

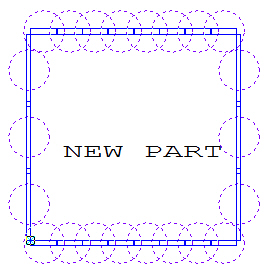

Print characters on the part(s) or sheet(s). |

MJC/IJP Setting |

Place the microjoint cut flags and the text

on the sheet. |

Notes: |

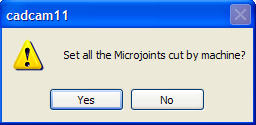

1. |

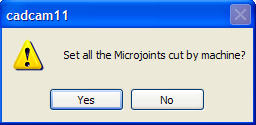

A message will prompt you

to select the MJC when selecting Apply in the Punching

Microjoints menu (Machine\Edit Material). The system

will generate the microjoints automatically according to the settings

in the Punching Microjoints panel when selecting Yes. |

|

|

2. |

You can add the microjoints

cut by the MJC machine manually using the Place Microjoint

option (Sequence Features/Punch Microjoint). |

3. |

The machine driver must

support the MJC function, or the MJC section in the Microjoint

properties window will be absent. |

|

|

|

Option |

Description |

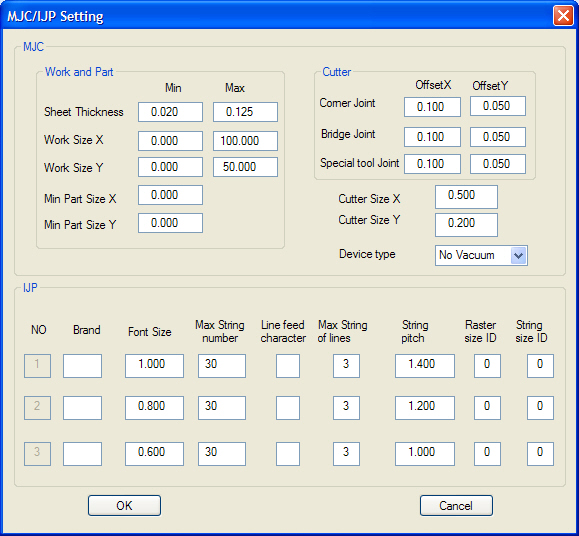

MJC |

Micro Joint Cutter |

Work and Part |

|

Sheet Thickness |

Specifies the thickness range for MJC cutting.

(Default Value: Min = 0.4, Max = 3.2.) |

Work Size X |

Specifies the work size for MJC cutting

in the X direction. (Default Value: Min X = 900, Max X = 2500.) |

Work Size Y |

Specifies the work size for MJC cutting

in the Y direction. (Default Value: Min Y = 900 and Max Y = 1250.) |

Min Part Size X |

Specifies the minimum part size for MJC

cutting in the X direction. (Default Value: X = 120.) |

Min Part Size Y |

Specifies the minimum part size for MJC

cutting in the Y direction. (Default Value: Y = 50.) |

|

Note: the part size is calculated

according to the overall rectangular size. |

Cutter |

|

Corner Joint |

Specifies the offset value of the MJC cutting

coordinate. The range can be set from 0.0 to 9999.9999. The offset

value is added according to the coordinate. If the cutter rotates,

the coordinate axis will also rotate (Default Value: X = 0.0,

Y = 0.0.) |

Bridge Joint |

This is the same as a microjoint. (Default

Value: X= 0.0 Y= 0.0.) |

Special Tool Joint |

This is the same as a microjoint. (Default

Value: X= 0.0 Y= 0.0.) |

Cutter Size X |

Specifies the horizontal cutter size. The

cutter is inserted into the hole that has been punched out. Defines

the hole for the MJC cutting coordinate in the X direction. (Default

value: X = 30.0.) |

Cutter Size Y |

Specifies the vertical cutter size. The

cutter is inserted into the hole that has been punched out. Defines

the hole for the MJC cutting coordinate in the Y direction. (Default

value: Y = 5.0.) |

Device Type |

This is the device type: No Vacuum/Vacuum.

(Default Value: X = 0.0 Y = 0.0.) |

IJP |

Ink Jet Printer |

No |

This is the flow number. |

Brand |

The manufacturer of the IJP device. H =

Hitachi, U = Union. |

Font Size |

The size of the font. |

Max String Number |

Specifies the maximum number of characters

that can printed. |

Line Feed Character |

Specifies the line-feed code used in printing

several character strings. |

Max String of Lines |

Specifies the maximum number of lines that

can be printed. |

String Pitch |

Specifies the pitch for the character strings. |

Raster Size ID |

Character size information that is sent

to the IJP. The printer will use the raster size and string size

information to determine the actual character size and pitch when

printing. (This is used to draw the interference. Check with the

hole during simulation. The actual character size is determined

by this information.) |

String Size ID |

This is the character size ID that is sent

to the IJP. |

OK |

Applies the settings to the current session. |

Cancel |

Exits without saving the changes. |

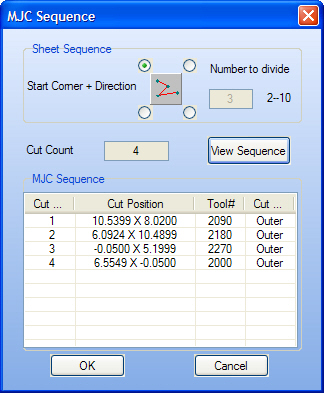

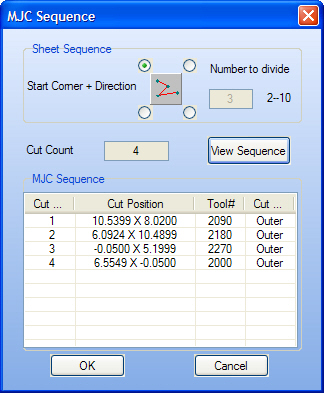

You

must define the MJC sequence after specifying the parameters.

Select MJC Sequence from the MJC/IJP submenu. The

options in this window allow you to define the parameters for

the micro-joint cutting. |

|

Option |

Description |

Sheet

Sequence |

Define the sheet sequence

for microjoint cutting. |

Start

Corner + Direction |

The radio buttons represent

the actual starting corner: Upper Left, Upper Right, Lower Left

or Lower Right. The button in the center functions as a toggle,

allowing you to specify the direction. |

Number

to Divide |

Set numbers of divided sections. |

Cut

Count |

Indicates the number of microjoints

to be cut. |

View

Sequence |

Select to view the sequence. |

MJC

Sequence |

Specifies the part processing

sequence. |

Cut

Sequence |

The cut sequence of the microjoint

on the sheet. |

Cut

Position |

The actual coordinates of

the microjoint. |

Tool

# |

The station number containing

the cutter tool. |

Cut

Type |

The type of cut. |

OK |

Applies the settings to the

current session. |

Cancel |

Exits without saving any

changes. |

Defining the text printed

on the part(s) involves selecting the field codes used to print

specific information on them. For example, if selecting the field

code that represents the Part File Name, the system will

print the name of the actual CAD file on the part. |

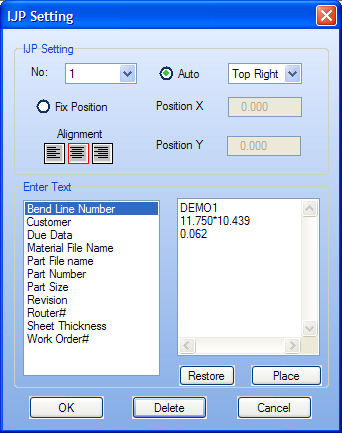

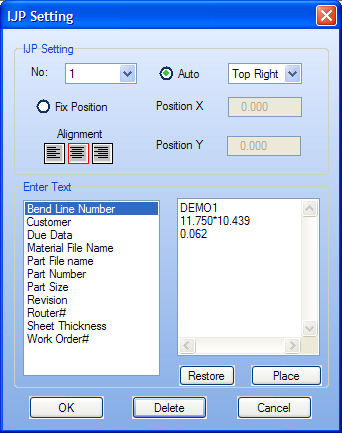

Select IJP Text from

the MJC/IJP submenu in order to define the text. The IJP

Setting window will appear. The options in this window allow

you to select which information you want printed on the part(s). |

|

Option |

Description |

IJP Setting |

|

No |

Select a machine number (No) from

the drop-down list: 1-3. |

Auto |

The system automatically places the text

according to your selection from the drop-down list: Top Right,

Top Left, Bottom Right or Bottom Left. |

Fix Position |

Specifies the exact position by typing coordinates

in the Position X and Position Y text boxes. |

Position X |

This option only becomes available if you

select Fix Position. (This is the IJP position in X direction.) |

Position Y |

This option only becomes available if you

select Fix Position. (This is the IJP position in Y direction.) |

Alignment |

Left, Center and Right alignment buttons

allow you to specify the origin output for the text. |

Left |

The text will be placed with the origin

output relative to the left. |

Center |

The text will be placed with the origin

output relative to the center. |

Right |

The text will be placed with the origin

output relative to the right. |

Enter Text |

The two lists in this section allow you

to select the text that will be placed on the part(s). |

Text List |

Double-click an item in the list to add

content to the Text Box on the right. |

Text Box |

Type the text that you want to print on

the part(s). |

Restore |

Recall any text previously typed in the

Text Box. |

Place |

Place the text on the part automatically

according to the Auto or Fix Position settings. |

OK |

Applies the settings to the current session. |

Delete |

Removes the text from the part. |

Cancel |

Exits without placing the text on the part. |