Cut Microjoint

Options

Use the Auto Microjoint, Add Microjoints, Edit

Microjoints and Delete Microjoint

options to add microjoints to cutting paths and modify or delete existing

microjoints.

The

Auto Microjoint option on the Cut Features submenu will

automatically place bridge and corner microjoints using the parameters

you have specified in the Cutting Microjoints panel of the Material Information

window.

The

Auto Microjoint option on the Cut Features submenu will

automatically place bridge and corner microjoints using the parameters

you have specified in the Cutting Microjoints panel of the Material Information

window.

If

your machine is equipped with a MJC (Micro Joint Cutter) device, you can

choose whether to have the joints processed by the machine. Click Yes

in

the dialog, the

joints will be cut by the MJC device. The system will determine the joint

type (corner joint, bridge joint, special tool joint) and angle automatically.

Click No to have the

system will use the designated relief tool in the turret to cut the microjoints,

or adjust the tools along the paths using the parameters in the Punching

Microjoints panel to create the microjoints.

To add a microjoint to a cutting path, while in Part view select

Add Microjoints from the Cut Features submenu. Move into

the work area. Move the pointer to position the cutting microjoint along

the length of the pattern. If you want to choose a different pattern,

click the right mouse button. Select the correct pattern and click the

left mouse button. The positioning marker hesitates at the snap points

so you can easily select the point. The Microjoint flyout window appears.

You can specify the properties of the microjoint(s) at this point, or

edit the microjoint(s) using the Edit Microjoints option.

To add a microjoint to a cutting path, while in Part view select

Add Microjoints from the Cut Features submenu. Move into

the work area. Move the pointer to position the cutting microjoint along

the length of the pattern. If you want to choose a different pattern,

click the right mouse button. Select the correct pattern and click the

left mouse button. The positioning marker hesitates at the snap points

so you can easily select the point. The Microjoint flyout window appears.

You can specify the properties of the microjoint(s) at this point, or

edit the microjoint(s) using the Edit Microjoints option.

To modify

the microjoint attributes, when in Part view select Edit Microjoints

from the Cut Features submenu. Move into the work area. The pointer

toggles between the microjoints. When you click a microjoint, the Microjoints

flyout window appears and activates the interactive edit mode.

To modify

the microjoint attributes, when in Part view select Edit Microjoints

from the Cut Features submenu. Move into the work area. The pointer

toggles between the microjoints. When you click a microjoint, the Microjoints

flyout window appears and activates the interactive edit mode.

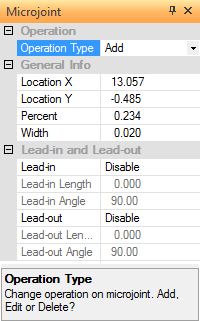

Whenever you add or edit

cutting microjoints, the Microjoint flyout window appears.

The window contains options that allow you to modify the attributes

of the selected microjoint, such as the width and the lead-in

or lead-out properties. |

|

Option |

Description |

Operation

Type |

There

are three options you can select from the drop-down list:

Add, Edit and Delete. |

Add |

The

Add option will appear by default when the system is in

Add Microjoints mode. Select Add from the Operation Type

drop-down list if you want to add microjoints, rather

than edit or delete microjoints. The system remains in

Add Microjoints mode until you select another option. |

Edit |

The

Edit option will appear by default when the system is

in Edit Microjoints mode. Select Edit from the Operation

Type drop-down list if you want to modify the microjoints,

rather than add or delete microjoints. The system remains

in Edit Microjoints mode until you select another option. |

Delete |

Select

Delete from the Operation Type drop-down list if you want

to remove microjoints. You can then move into the work

area and select those microjoints that you want to remove

from the patterns. The system remains in Delete Microjoints

mode until you select another option. |

General

Info |

This

section of the Microjoints flyout window displays

general information about the selected microjoint. |

Location

X |

This

field displays the X coordinate of the microjoint. A new

location button appears to the right of the

field when you select the label, allowing you to modify

the X coordinate of the microjoint. |

Location

Y |

This

field displays the Y coordinate of the microjoint. A new

location button appears to the right of the field

when you select the label, allowing you to modify the

Y coordinate of the microjoint. |

Percent |

The

paths on which you place microjoints are considered sets

of individual segments (line segments and arc segments).

The value that appears in this field represents the distance

of the microjoint from the beginning of the current segment

(this is not the distance from the start point of the

path). You can type a number to alter the position of

the microjoint. |

Width |

This

field displays the width of the microjoint. You can type

a new value to modify the width during either Add Microjoints

or Edit Microjoints mode. |

Lead-In

and Lead-Out |

The

options in the Lead-In and Lead-Out section of the Microjoints

window allow you to control the application of lead-in

and lead-out lines to the microjoints. The software automatically

places a lead-in or lead-out on every microjoint using

the settings from the Lead In/Lead Out section in the

Cutting Microjoints panel of the Material Information

window. |

Lead-in |

To

apply a lead-in line to the microjoint, select Enable

from the Lead-in drop-down menu. Select Disable from the

drop-down menu to suppress the application of a lead-in

line to the microjoint. |

Lead-in

Length |

Type

a length value for the microjoint lead-in line. |

Lead-in

Angle |

Type

an angle value for the microjoint lead-in line. |

Lead-out |

To

apply a lead-out line to the microjoint, select Enable

from the Lead-out drop-down menu. Select Disable from

the drop-down menu to suppress the application of a lead-out

line to the microjoint. |

Lead-out

Length |

Type

a length value for the microjoint lead-out line. |

Lead-out

Angle |

Type

an angle value for the microjoint lead-out line. |

|

Delete Microjoint

When

in Part view, left-click the icon and the cursor will be come a blue box

that snaps to the nearest microjoint when moved into the work area. Left-click

to delete.

To add a microjoint to a cutting path, while in Part view select

Add Microjoints from the Cut Features submenu. Move into

the work area. Move the pointer to position the cutting microjoint along

the length of the pattern. If you want to choose a different pattern,

click the right mouse button. Select the correct pattern and click the

left mouse button. The positioning marker hesitates at the snap points

so you can easily select the point. The Microjoint flyout window appears.

You can specify the properties of the microjoint(s) at this point, or

edit the microjoint(s) using the Edit Microjoints option.

To add a microjoint to a cutting path, while in Part view select

Add Microjoints from the Cut Features submenu. Move into

the work area. Move the pointer to position the cutting microjoint along

the length of the pattern. If you want to choose a different pattern,

click the right mouse button. Select the correct pattern and click the

left mouse button. The positioning marker hesitates at the snap points

so you can easily select the point. The Microjoint flyout window appears.

You can specify the properties of the microjoint(s) at this point, or

edit the microjoint(s) using the Edit Microjoints option. To modify

the microjoint attributes, when in Part view select Edit Microjoints

from the Cut Features submenu. Move into the work area. The pointer

toggles between the microjoints. When you click a microjoint, the Microjoints

flyout window appears and activates the interactive edit mode.

To modify

the microjoint attributes, when in Part view select Edit Microjoints

from the Cut Features submenu. Move into the work area. The pointer

toggles between the microjoints. When you click a microjoint, the Microjoints

flyout window appears and activates the interactive edit mode.![]()