Right Angle Shearing Manual

What is Right Angle Shearing?

|

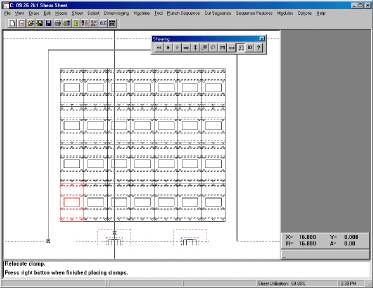

The Right Angle Shearing module is an optional

software package that enhances the functionality of the CAD/CAM

System. If your machine driver supports right angle shearing on

right angle shearing machines, or a machine with a right angle

shear, then you will want to review the information presented

in this manual.

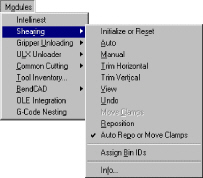

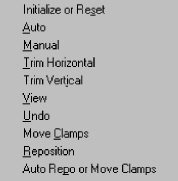

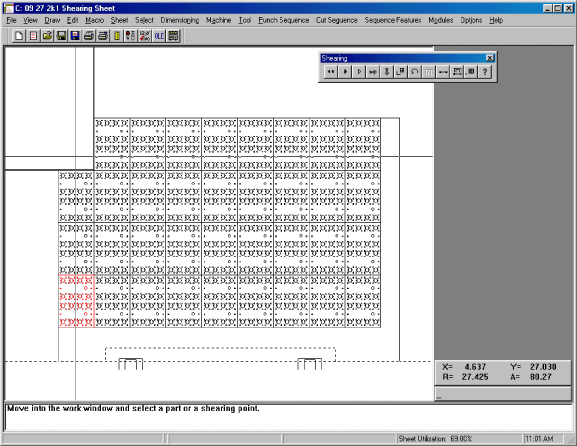

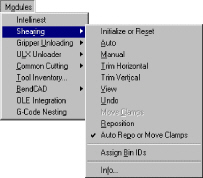

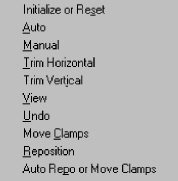

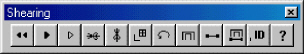

The Shearing option is located on the Modules menu. To access the

options on the Shearing submenu, you must first open the Modules

menu, and then select the option (using either the mouse or keyboard)

to list the commands.

To ensure the options on the Shearing submenu are active when you

begin your session, the following conditions must be in effect:

1. Your machine driver must support shearing

functions.

Sheet

view must be active. You cannot use the shearing options if

Part view is active. If the Info

option is active, but the remaining

options are disabled, you must first use the Info option

to specify the right angle shear information. |

Quick Start Guide

The Quick Start Guide summarizes the shearing

process. Review this outline of the Shearing features. For commands or

tasks you do not fully understand, reference the appropriate section.

Start Right

Angle Shearing

To

prepare for Right Angle Shearing, launch the CAD/CAM System. Select Sheet

from the View menu. Sheet view must be active before you can use any of

the options on the Shearing submenu.

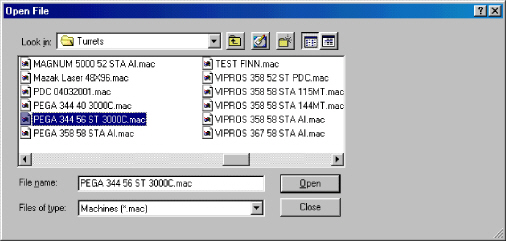

Load the Machine File

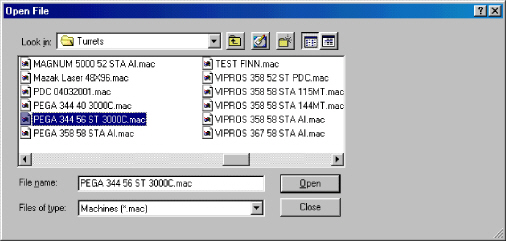

Select Open

from the File

menu, or click the Open File button in the

Standard toolbar. When the Open File dialog box appears, select

Machines (*.mac) from

the Files of type:

drop-down list. The system lists the machine files stored in the \Turrets

directory by default. If necessary, use the Look

in: drop-down list to navigate the

hierarchical folder structure. Scroll through the file list window and

click the name of the machine file. Click Open

to load the machine file. If necessary, edit

or load a material file. Click Close

to exit the Open File dialog box.

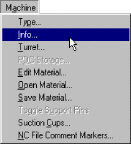

Load the Machine Driver

|

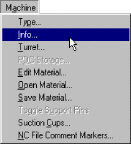

Select

Info from

the Machine menu

to open the Machine Setup window. Click the Driver File button.

The Open dialog box displays the machine drivers stored in the

\Machine directory by default. If necessary, use the Look in:

drop-down list to navigate the hierarchical folder structure.

Scroll through the file list window and click the name of the

driver file. If necessary, edit or load a material file. Close

the Machine Setup window.

|

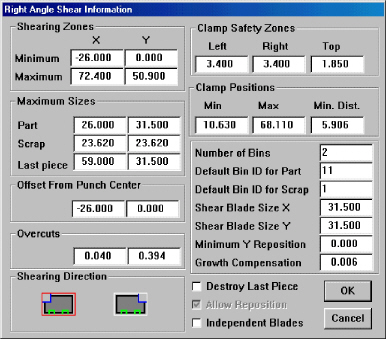

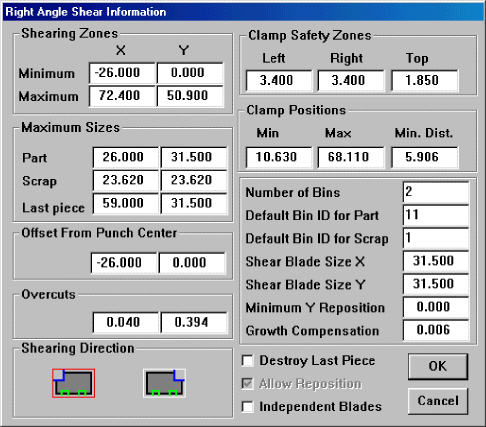

Specify the Right Angle Shear Information

Open the Modules

menu. Select Info

from the Shearing

submenu to open the Right Angle Shear Information

window. Specify the Shearing Zones, Maximum Sizes, Offset From Punch Center,

Overcuts, Shearing Direction, Clamp Safety Zones, Clamp Positions and

Bin ID data.

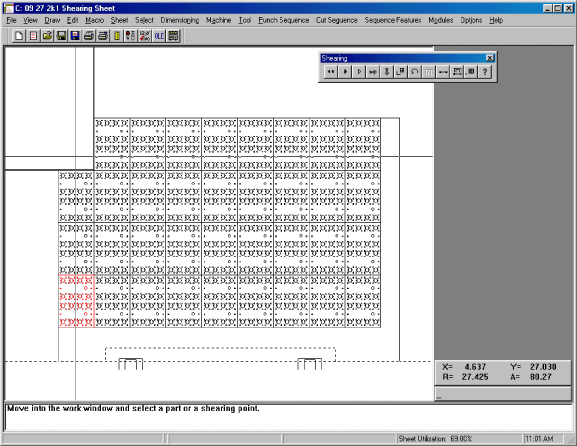

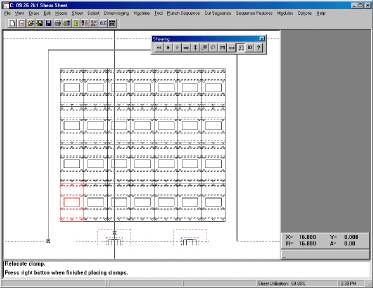

Create the Right Angle Shearing Sheet

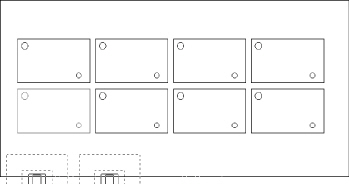

Load the parts on the sheet and grid them if

necessary. Assign the tools to the patterns. Assign the Bin IDs.

Load the parts on the sheet and grid them if

necessary. Assign the tools to the patterns. Assign the Bin IDs.

Use the Shearing Options

Use

the options on the Shearing submenu to define the shearing sequence.

Save the Shearing Sheet

Select Save

As from the File

menu, or click the Save As button in the Standard

toolbar to open the Save As dialog box. Select Sheets

(*.sht) from the Save

as type: drop-down list. Type an appropriate

name in the File name:

text box. Click the Save button to save the Shearing sheet. Click

Close to

exit the dialog box.

Select Save

As from the File

menu, or click the Save As button in the Standard

toolbar to open the Save As dialog box. Select Sheets

(*.sht) from the Save

as type: drop-down list. Type an appropriate

name in the File name:

text box. Click the Save button to save the Shearing sheet. Click

Close to

exit the dialog box.

Overview

The

basic procedure for using right angle shearing includes:

Review or specify the right angle shearing

information.

Review or specify the information for

the clamp safety zones.

Choose the shearing method, either automatic

or manual.

Choose the trimming method, either vertical

or horizontal.

Use either automatic repositioning or

manual repositioning.

Adjusting the clamp placement.

If necessary, using the Undo option to

reverse unwanted results.

Using the View command to see the shearing

sequence.

Preparation

To

prepare your system to use the shearing features:

Load your machine file, record the shearing

information, and bin information. You will want to save the machine

file to record the information for future production sheets.

Install your shearing machine driver as

outlined in the directions that accompanied it. Note: Only Version 5.x and later versions of the

CAD/CAM System support right angle shearing features.

Load the Machine File

A machine file contains the physical parameters

of a machine. You must load the correct machine file before you can define

a sheet having shearing functions. Machine files have the filename extension

of *.mac,

and are stored in the \Turrets directory by default.

To load the machine file:

Select Open

from the File menu, or click the Open

File button in the Standard toolbar. The Open File dialog box appears.

Click the Files

of type: arrow and select

Machines (*.mac) from

the drop-down list.

If necessary, use the Look

in: list to navigate the hierarchical

folder structure.

Scroll

through the file list window and click the name of the machine file

you want

to load.

- Click Open to load

the machine file, and then click Close

to exit the dialog box.

Load the Machine Driver

|

The next step involves checking the machine

driver, and if necessary, selecting the correct driver that supports

shearing functions. Your machine driver must support shearing.

Please contact your CAD/CAM System representative for more information

on custom drivers.

Select Info

from the Machine

menu to open the Machine Setup

window. The Setup Values page displays by default. Click

the Driver File  button in Machine

Driver section. When the Open

dialog box appears, the name of the current driver displays

in the File name: text box. button in Machine

Driver section. When the Open

dialog box appears, the name of the current driver displays

in the File name: text box.

If the driver is correct, then click

the Close button to exit the Open dialog box.

To load an alternate driver, navigate through the file list

and click the name of the driver you want to load. Click the Open

button to load the driver. You

may be prompted to create or load a material file.

See the Material Files section

in Chapter 7: Machine Files of the CAD/CAM System manual for

more information. Click

Save in the Machine Setup window. |

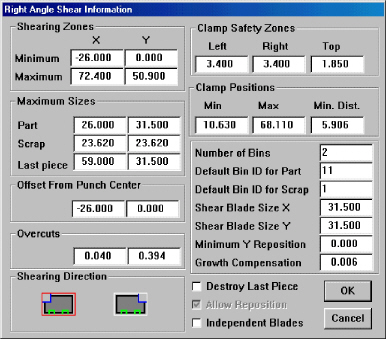

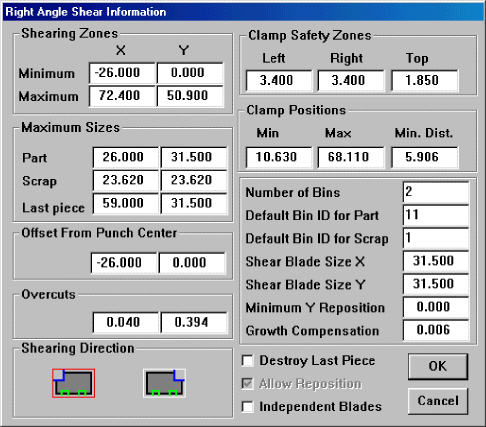

Right Angle Shear Information Window

You

must specify the right angle shear information before you can use any

of the options. If this information already exists in the machine driver,

then you only need to examine the values to ensure they are correct. If

necessary, you can view and edit the values using the Right Angle Shear

Information window.

To

display the Right Angle Shear Information window:

Make sure Sheet view is active. If necessary,

select Sheet from

the View menu.

Open the Modules

menu, and highlight (select) Shearing to

open its submenu.

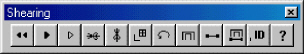

Select Info

from the Shearing

submenu, or click the Info button in the

Shearing toolbar. When the Right Angle Shear Information window opens,

the contents of the X Minimum

text box in the Shearing Zones section

are selected by default.

Type

the values in the text boxes. You can navigate the text box fields

within the window using a combination of the <Tab> and <Shift>

keys. Press <Tab> to move to the next field, or <Shift>

+ <Tab> to select the contents of the previous field.

When the information appears correct, click

the OK button

to save the changes and to exit the Right Angle Shear Information

window.

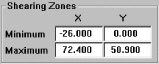

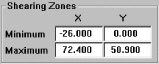

Shearing

Zones

|

The shearing zone

is the area that your machine driver can shear. The text boxes

in this section allow you to specify the minimum and maximum X

and Y values for the shearing zone. The CAD/CAM System measures

these values from the lower left sheet corner. |

Shearing

Zones Values |

Minimum

(X and Y) |

These

fields allow you to specify the X and Y values for the minimum

shearing boundary. Type the value that represents the furthest

left position for shearing in the X text box, and the value representing

the lowest

position available for shearing in the Y text box. |

Maximum

(X and Y) |

These

fields allow you to specify the X and Y values for the maximum

shearing boundary. Type the value that represents the furthest

right position available for shearing in the X text box, and the

value representing the highest position for shearing in the Y

text box. |

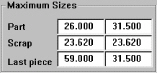

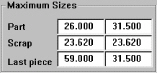

Maximum

Sizes

|

This section allows

you to specify the maximum sizes for parts,

remaining scraps and the last piece. |

Maximum

Sizes Values |

|

Part

(X and Y) |

Type

the maximum size for the largest part your machine can shear in

the X and Y fields following the label. |

|

Scrap

(X and Y) |

Type

the maximum size for the remaining scrap in the X and Y fields

following the label. |

|

Last

Piece (X and Y) |

Type

the maximum size for the last piece in the X and Y fields following

the label. |

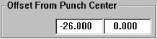

Offset

From Punch Center |

|

Type the X and Y

coordinates for the shear blade's offset from the punch center

in these text boxes. The distance is measured from the punch head

to the shear blade. (The punch head is considered “0, 0”.) You

must consult your machine's user guide or manual for this information. |

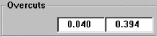

Overcuts |

|

The overcut is the

amount you want the blade to overlap hits when multiple hits are

required to remove the material. (This is similar to “nibbling”

in punching.) You must consult your machine's user guide or manual

for this information. |

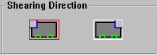

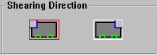

Shearing

Direction

|

The options in this

section allow you to specify whether shearing should proceed from

left to right or right to left.

to

shear from left to right. to

shear from left to right. |

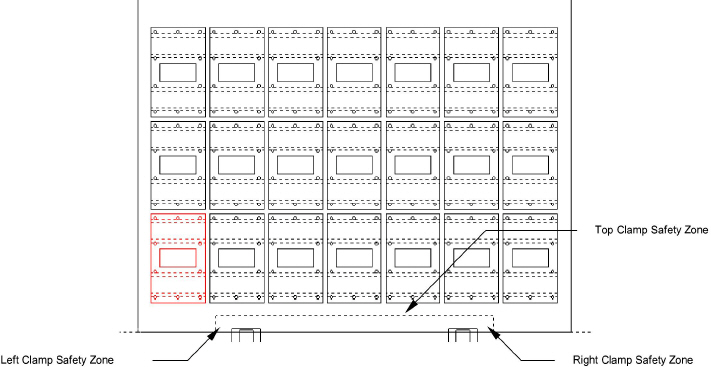

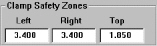

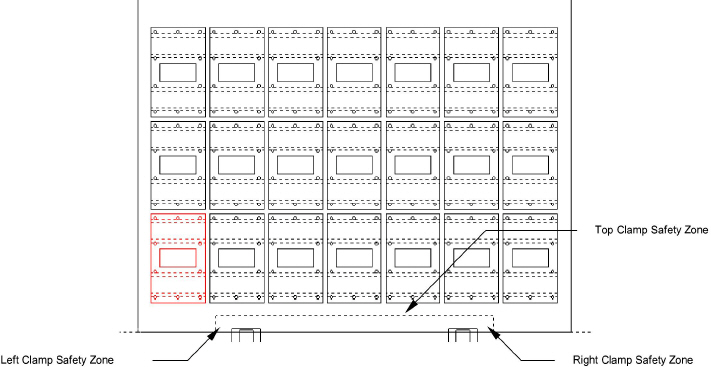

Clamp

Safety Zones

|

to

shear from right to left. to

shear from right to left.

You use this

section to specify the safety zone required to the left of left-hand

clamp, to the right of the right-hand clamp and above the tops

of the clamps. Note: The shear cannot cut between clamps. It

can only shear to the right or left side of the clamps. The system

moves the clamps

as needed when you use automatic shearing. |

Clamp Safety Zones

Values |

Left

Right

Top |

Type the amount of space required as a safety

zone on the left side of the far left clamp.

Type the amount of space required as a safety

zone on the right side of the far right clamp.

Type the amount of space required above

the clamps. |

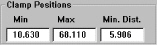

Clamp Positions

|

Use these settings

to specify the positions for clamps during right

angle shearing. |

Clamp Positions

Values |

Min |

Type the minimum

clamp position (as measured from the bottom left corner of the

sheet). |

Max |

Type the maximum

clamp position (as measured from the bottom left corner of the

sheet). |

Min. Dist. |

Type the minimum

distance between the clamps. |

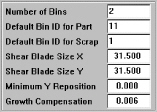

Bin

Information |

|

Bins

represent the destinations of the parts after shearing.

Notes:

You

cannot assign parts to bins until you specify the number of

bins. If

you specify a value of zero in the Number of Bins text box,

you cannot use the Assign Bin IDs option. |

Bin Information |

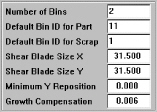

Number of Bins |

Type the number of bins used for shearing. |

Default Bin ID for

Part |

Type the bin number you want to use for

parts that are not assigned to any other bin. |

Default Bin ID for

Scrap |

Type the bin number for the bin you want

to use for scrap. |

Blade Size |

The Shear Blade Size X and Shear Blade Size

Y text boxes contain the X and Y dimensions for the size of your

machine's shearing blade. You must consult your machine's user

guide or manual to obtain these values. |

Shear Blade Size

X |

The X dimension of the machine's shearing

blade. The orientation is dependent on the sheet as it

appears within the program window. The X dimension is the measurement

from left to right. |

Shear Blade Size

Y |

The Y dimension of the machine's shearing

blade. The orientation is dependent on the sheet as it

appears within the program window. The Y dimension is the measurement

from bottom to top. |

Minimum Y Reposition |

This field contains the value for the lowest

position that can be sheared when repositioning is active. |

Growth Compensation |

The value you enter in this field allows

you to compensate for the amount the shear stretches the

metal. You must rely on your own experience with the materials

and machines to arrive at the correct value. Some shops use 0.005”

as a baseline and adjust the value as needed for various materials

and machines. You must experiment with this setting to determine

how it affects the other machine settings. Grids are often affected

by this setting. |

13 |

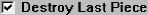

Destroy Last Piece

|

For auto-shearing, this option indicates

whether the last piece of scrap should be sheared down to a manageable

size. The option ensures that the last piece is smaller than the

maximum scrap size. |

Allow Reposition |

To destroy the last piece, make sure a check

mark is in the check box. If you want the last piece to remain

in whatever size naturally occurs, remove the check mark from

the check box. |

|

This option

indicates whether your machine is capable of repositioning the

sheet. If a check mark appears in the check box, your machine

allows repositioning. If the option is disabled, then your machine

does not allow repositioning.

Note:

The system examines the machine driver to determine whether repositioning

is allowed. However, to actually use repositioning, you must place

a check mark in the All Reposition check box. You must also select

the Auto Repo or Move Clamps option on the Shearing menu until

a check mark appears next to the option. |

Independent

Blades |

|

This option indicates whether the machine's

blades can function independently. The Salvagnini is an example

of this type of machine. If the machine's blades function independently,

make sure to place a check mark in the check box. If the machine's

blades work simultaneously, remove the check mark from the check

box. |

Bin IDs

|

Bins hold your

parts. You must specify the number of bins your machine uses and

an identification number for each bin. You must then assign a

part or parts to a particular bin. You use the Assign Bin ID option

for this purpose. Note: Before you attempt to assign the parts

to the bins, make sure to complete your bin information setup.

Select Info from

the Shearing submenu and enter a value in the

Number of Bins text box. You will also want to enter the

setup values for Default Bin

ID for Part and

Default Bin ID for Scrap. |

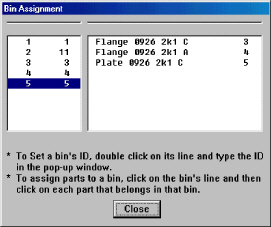

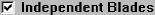

Assign Bin IDs

|

To

begin the process, select Assign

Bin IDs from the Shearing submenu,

or click the Assign Bin IDs button in the Shearing toolbar. The

Bin Assignment window is split into bin number and part list panes.

The bin numbers available for your machine appear in the pane

on the left; the parts are listed in the pane on the right.

See Bin Number and Bin ID. See

also Part Name and Bin ID. |

Bin Number and Bin

ID |

|

To assign an ID number for each bin, double-click

any line in the left pane of the Bin Assignment window. The Bin#

window appears in the lower left corner of the Bin Assignment

window. Type a code number in this window and press <Enter>.

Repeat this procedure for each bin. |

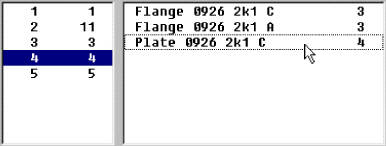

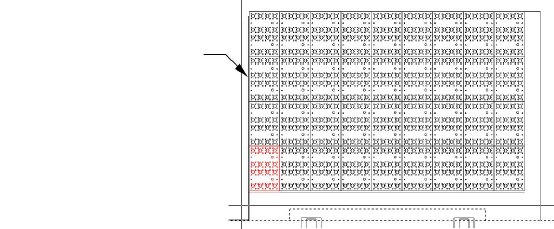

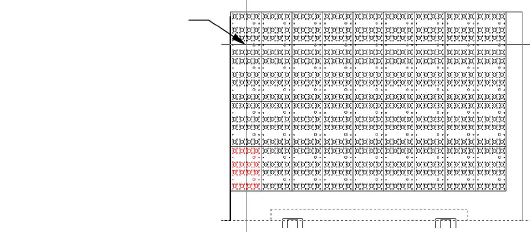

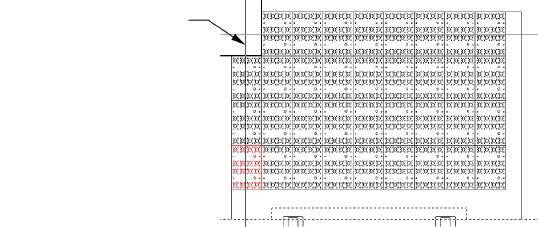

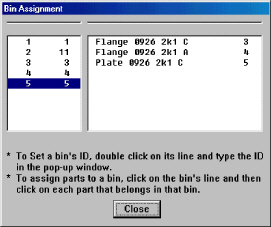

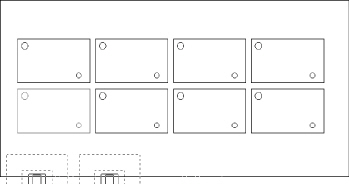

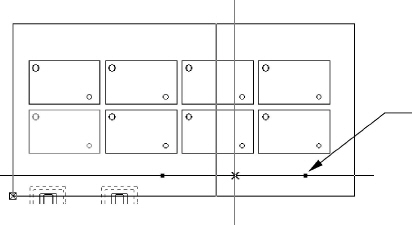

Part Name and Bin ID

The

next step involves assigning the parts to the bins. You want to click

a bin number in the left pane, and then click each part name you want

to assign to that bin. The following illustration indicates that the first

two parts are assigned to Bin# 3, while the third part is assigned to

Bin# 4.

To assign parts to a different bin, click the

next bin

number in the left pane, and then click the name of the part in the right

pane.

When

you have completed your bin assignments, click Close

to exit the Bin Assignment window.

When

you have completed your bin assignments, click Close

to exit the Bin Assignment window.

Shearing Options

You

have the choice of using either automatic or manual shearing. If time

is at a premium, then you may want the system to automatically shear the

sheet. If control over the shearing process takes priority, then try manual

shearing.

Automatic Shearing

If you choose to use automatic shearing, the

software determines how to shear the sheet. You can also choose to have

the system automatically reposition and move the clamps as needed, or

you can manually reposition the sheet. See

Using Automatic Repositioning and Using Manual Repositioning.

To

use automatic shearing:

Arrange

the parts on the sheet, and define the tool assignments and sequencing.

Select

Initialize or Reset from

the Shearing submenu,

or click the Initialize or Reset Shearing button in the Shearing

toolbar. The system prompts you to confirm. Press <Y> to reset

the shearing sequence or <N> to cancel.

|

|

Using Automatic

Repositioning |

|

Using Manual

Repositioning |

|

Manual Shearing

Manual shearing allows greater control the

shearing process. The overall procedure involves initializing the

sheet for shearing, choosing a trimming option, or manually shearing

the parts from the sheet.

Initialize or

Reset Shearing

You must first initialize the sheet before performing

any manual shearing. If necessary, select Initialize

or Reset from the Shearing submenu,

or click the Initialize or Reset Shearing button in the Shearing toolbar.

You must first initialize the sheet before performing

any manual shearing. If necessary, select Initialize

or Reset from the Shearing submenu,

or click the Initialize or Reset Shearing button in the Shearing toolbar.

The system prompts you to confirm. Press

<Y> to reset the shearing sequence. Press <N> to cancel.

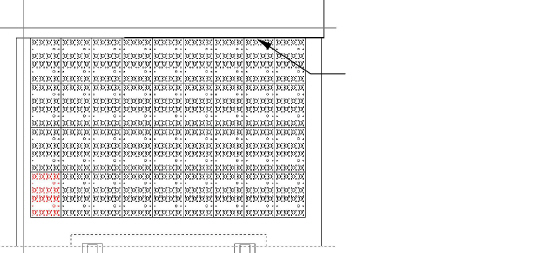

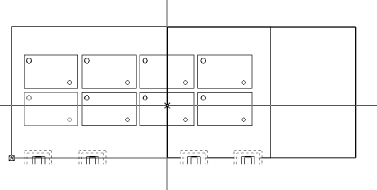

Trimming the Sheet

You must trim any material surrounding the

parts from the sheet before you can manually shear individual parts.

The Trim Horizontal and Trim Vertical options are used for this purpose.

Trim Horizontal

To trim the sheet

horizontally, select Trim Horizontal

from the Shearing

submenu, or click the Trim Horizontal

button on the Shearing toolbar. Move into the work area and position

the crosshair over the top row of parts. Click the right mouse button

to snap to the top edge. Click the left mouse button to shear the

sheet along the top.

Note: If the sheet is large enough to require repositioning,

you cannot trim horizontally. You will have to manually shear the

tops of the parts instead.

Choose Trim Horizontal and move into the

work area. If necessary, click the right mouse button to snap to the

top edge of the row of parts. Click the left mouse button to trim.

Trim Vertical

To trim the sheet vertically, select Trim

Vertical from the Shearing submenu, or click the Trim Vertical button

on the Shearing toolbar. Move into the work area and position the

crosshair over the left column of parts. Click the right mouse button

to snap to the left edge. Click the left mouse button to shear the

sheet along the left.

Choose Trim Vertical and move into the work

area. If necessary, click the right mouse button to snap to the left

edge of the column of parts. Click the left mouse button to trim.

Shearing Individual

Parts

The Manual option on the Shearing submenu

allows you to manually shear individual parts or portions of scrap

from the sheet.

To shear individual

parts out of the sheet, select Manual

from the Shearing

menu, or click the Manually Shear Sheet

button in the Shearing toolbar. You can now shear manually using one

of three methods:

To

shear along the top of a part, click the right mouse button to

snap to the top right corner, and then click the left mouse button.

To

shear along the left of a part, click the right mouse button to

snap to a line on the left side of the part, and then click the

left mouse button.

To

shear the part, move the crosshair over the part and click the

left mouse button. (As an alternative, you can use the right mouse

button to snap onto the bottom right corner of the part and then

click the left mouse button to shear.)

Select Manual from the Shearing submenu,

and click the part you want to shear manually.

The system shears the part from the sheet.

The part disappears from the work area.

Undo

|

To reverse

the last shearing sequence, select Undo

from the Shearing

submenu, or click the Undo Shearing

button in the Shearing toolbar. The option allows you to eliminate

the last function added to the shearing sequence without resetting

the entire sequence. Note: Be careful using the Undo command.

While the option is capable of reversing multiple shearing

operations, it can also remove the original punch or cut sequencing

you assigned to the inside patterns. |

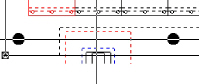

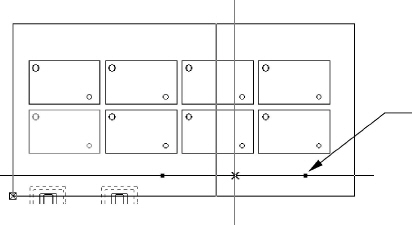

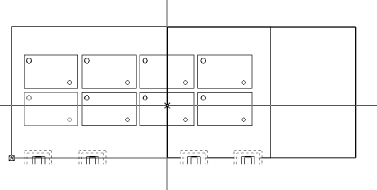

Move Clamps |

|

The Move Clamps option is available

only if the machine driver supports moving the clamps during

sequencing or shearing.

To move the clamps:

Select

Move Clamps from

the Shearing

submenu, or click the Move

Clamps button on the Shearing toolbar. Move the crosshair into the

work area. Two round markers that represent the reposition

posts begin to follow the crosshair.

Move the crosshair onto a clamp

and click the left mouse button. The system prompts you

to select the clamp. Click the left mouse button again.

The system prompts you to relocate the clamp. Move the

mouse along the X-axis of the sheet edge to position the

clamp. Repeat this step for each clamp. See the illustration

below. When you have relocated each

clamp, click the right mouse button to continue with other

sequencing activities.

|

Reposition

|

Repositioning

allows you to use sheet sizes longer than your machine's maximum

X travel. The Reposition option opens the clamps and moves

them so you complete the remainder of the sheet. You can also

reposition in the reverse direction to return the clamps to

their original position so the sheet does not hang off the

edge of the table.

To reposition the clamps during a shearing sequence, select

Reposition from

the Shearing

submenu, or click the Reposition

button on the Shearing toolbar. The prompt instructs you to

move into the work area and set the reposition location. As

you move the pointer across the sheet, the reposition line

appears and the prompt asks you to choose its location. The

location of the reposition line relative to the lower left

corner of the sheet indicates the direction and distance you

want the clamps to move. As you move closer to the edge of

the sheet, you will see a rectangle following the pointer.

This represents the machine bed.

The patterns

that appear inside this rectangle are within range. When the

patterns you want to sequence with shearing functions appear

inside the rectangle, click the left mouse button. The repositioning

line locks onto the sheet, and two solid blocks that represent

the positioning posts appear. The repositioning posts follow

the pointer around the work area and a prompt instructs you

to choose their placement. Make sure the posts do not fall

inside a cutout on the part. When you are satisfied with the

location, click the left mouse button. You can continue to

sequence the sheet. To reposition back to the original location,

place the left position line at X=0.000; the clamps return

to their original location.

Notes:

For the minimum reposition,

place the right position line as close to the farthest

pattern as possible. The pattern is within range while

inside the reposition lines. When repositioning multiple

parts, you should place out-of-range parts in a separate

grid. |

|

You must reposition if your sheet

extends beyond the table limits. While

the Add option is active, select

Reposition from the Sequence Options

window. |

|

Use the mouse and crosshair to locate

the reposition line, and then click the left mouse button. |

|

Use the mouse and crosshair to position

the holddowns. Make sure not to locate the posts over a large

hole on the sheet, and then

click the left mouse button. |

Auto Repo or Move

Clamps

|

The Auto

Repo or Move Clamps option controls whether the system automatically

repositions or prompts you for a reposition. If you want the

system to perform an automatic reposition, select Auto Repo or Move Clamps on the Shearing

menu until a check mark appears

next to the option. If you want the auto shearing process

to stop and prompt you for a reposition when the sheet requires

a clamp movement or reposition, remove the check mark from

the option. Note: The Activate Repo button on the Shearing

toolbar is a toggle. |

Initialize or

Reset |

|

This option

prepares the sheet for shearing and resets any existing shearing

sequence. It does not affect any cutting or punching sequencing

you defined before the shearing. However, any punch or cut

sequencing you perform after shearing is reset when you select

the option. You must use Initialize or Reset before choosing

either Auto or Manual from the Shearing menu. Select

Initialize or Reset from the Shearing

submenu, or click the Initialize

or Reset Shearing button in the Shearing toolbar. The system

prompts you to confirm. Press <Y> to reset the shearing

sequence. Press <N> to cancel. |

View Shearing

|

To

see the shearing sequence, select View

from the Shearing

submenu, or click the View Shearing

button on the Shearing toolbar. Note: Use the Viewing Speed command on the

Options menu to control the redraw rate of the sequence. |

Saving the Shearing

Sheet |

|

You should

save your sheet frequently to prevent data loss during power

outages or computer crashes. If you press the <F10>

key while in Sheet view, the system saves your sheet under

its assigned name in its default folder. Note:

If you have not yet named the sheet, pressing <F10>

saves the sheet with the default name of NEW SHEET.

To save the sheet:

Make sure you are in Sheet

view. To save the sheet under a new name, select Save

As from the File menu, or click the Save As button in

the Standard toolbar. The Save As dialog box appears. If

necessary, select Sheets

(*.sht) from the

Save as type:

list. Type a name in the File name: text box. You need

not add the filename extension; the system automatically

adds the *.sht

extension. Click

the Save button to save the sheet. Click

the Close button to exit the Save As dialog

box. |