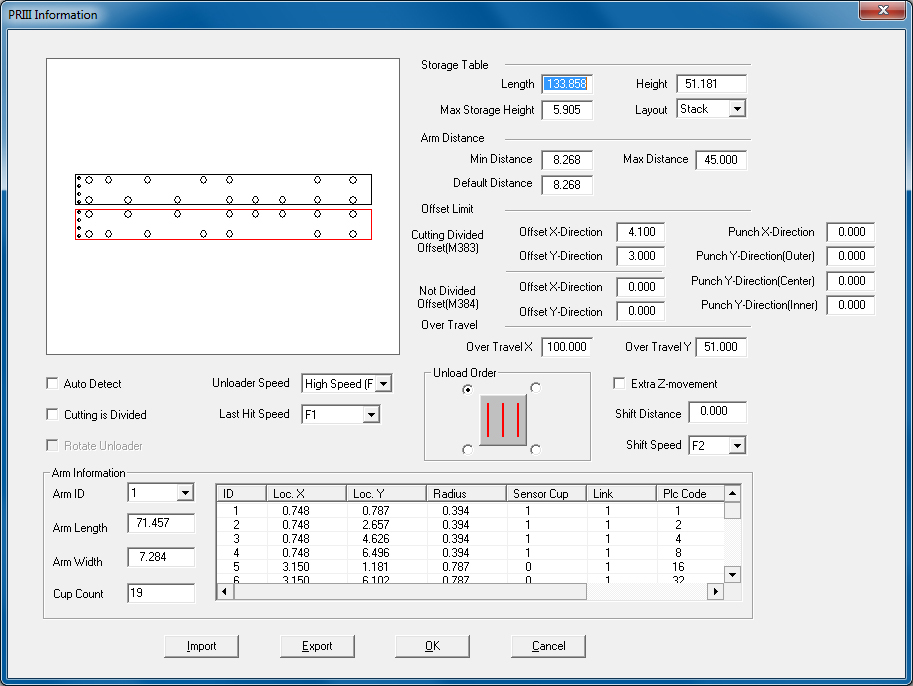

Whether you select Info from the PRII or PRIII Unloading submenu, the Information Setup window will appear. The options in the window allow you to specify the settings for the arms and storage table that compose the unloading device.

Notes:

1. When you select an arm, it will turn red in the preview area.

2. When you select a cup, it will turn red in the preview area.

3. Click the cells in the Arm Information table and make modifications to individual suction cups.

4. The options that appear in this window depend upon the driver/machine loaded.

A PRII window may have fewer options

Option

Description

Preview Area / Storage Table

The arm layout and suction cup layout will appear in the Preview area.

Length / Height

Location X / Y

Enter the location of the table.

Layout

Two different layout methods (Sheet/Stack) for auto unloading are supported. Sheet will place the parts as they appeared on the original sheet. Stack will stack the same parts (with the same rotation) one on top of the other within Max Storage Height limits.

Arm Distance

The settings in this section define the minimum and maximum distances between the arms.

Note: The Simulator supports part removal arms up to and longer that 70 inches.

Min Distance

The allowable minimum distance between the two arms.

Max Distance

The allowable maximum distance between the two arms.

Default Distance

The default distance between the two arms.

Offset Limit

The fields in the Offset Limit section display information for the offset from the punch head at the three track locations (or the laser head) as measured in the X and Y directions to the left bottom of the first arm.

Cutting Divided Offset(M383)

M383 will leave the last line uncut until the part remover arms come and stabilize the part, and then the last cut will occur.

Note: The Cutting is Divided check box must be enabled for this option to work.

Offset X-Direction

The offset from the turret station in the X direction.

Offset Y-Direction

The offset from the turret station in the Y direction.

Not Divided Offset(M384)

This option will cut out the last line first and then the part remover will comes to remove the part.

Note: Cutting is Divided must be unchecked.

Offset X-Direction

The offset from the turret station in the X direction.

Offset Y-Direction

The offset from the turret station in the Y direction.

Punch X-Direction

The distance from the tool to the part remover arms in the X direction.

Punch Y-Direction

The distance from the tool to the part remover arms in the Y direction.

Over Travel

Specify the vertical maximum over travel for the arms to ensure the arms are within the specified Y traveling range.

Over Travel X

Set the value for overtravel in X.

Over Travel Y

Set the value for overtravel in Y.

Note: If the Y value of the parts exceed the “Over Travel Y” value, AP100US will always set “arm2 (or B arm)” as the based arm.

Auto Detect

If you place a check mark in the Auto Detect check box, the system will detect the cup status (On/Off) automatically when you edit the arm.

Cutting is Divided

If the X coordinate of the last cut does not have any movement and this option is enabled, the outer loop of the part will be divided. If you remove the check mark, the outer loop will not be divided.

Rotate Unloader

Check this box to allow the arms of the TK Unloader to rotate.

Note: This is a driver-dependent option, and will not function with all drivers.

Last Hit Speed

If the machine speed is too fast, a loose part may crash the turret. Use the Last Hit Moved Speed function to control the machine speed to avoid this problem.

Select one of the four speed values - F1 is the fastest speed while F3 is the lowest. The system will output the selected last hit tool moved speed in the NC code.

Unloader Speed

Select the unloading speed from the drop-down list.